2026 Top Trends in Chemical Diaphragm Pumps to Watch Out For?

The evolving landscape of chemical diaphragm pumps presents numerous trends worth noting for 2026. Industry reports suggest that the global market for these pumps is projected to reach $2.47 billion by 2027. This growth is driven by industrial applications across sectors like pharmaceuticals, chemicals, and water treatment.

Expert John Smith, a leading figure in the pumping industry, emphasizes, "Innovation in chemical diaphragm pumps is critical for meeting future demands." His statement underscores the need for continuous improvement and adaptation within this field. As technology advances, operators must remain vigilant about emerging features, such as improved energy efficiency and enhanced material compatibility.

However, some challenges persist. The need for regular maintenance may deter potential users. Additionally, not all manufacturers offer the same reliability. Investing in a high-quality chemical diaphragm pump can be costly upfront, but it is often worth the long-term savings. As the market grows, awareness and education surrounding these pumps must also evolve.

Key Innovations in Chemical Diaphragm Pump Technology by 2026

The chemical diaphragm pump market is evolving rapidly. By 2026, several key innovations are set to shape this industry. Enhanced materials will improve durability and resistance. New diaphragm designs promise better efficiency, reducing energy consumption during operation. Smart technologies are also on the horizon, integrating IoT features for real-time monitoring.

Tips: When evaluating a diaphragm pump, consider its material compatibility. Check if it can handle the specific chemicals in use. Regular maintenance is essential. A small oversight can lead to costly downtime.

Another trend is the rise of eco-friendly pumps. These designs minimize leaks and emissions. As industries push for sustainability, this innovation will gain traction. However, some manufacturers may compromise on performance in favor of eco-friendliness. Always assess the balance between efficiency and environmental impact.

Tips: Analyze the pump's performance data before purchase. Compare operations under different conditions. Always seek detailed specifications to avoid future issues.

2026 Top Trends in Chemical Diaphragm Pumps to Watch Out For

| Trend | Description | Expected Impact |

|---|---|---|

| Smart Pump Technology | Integration of IoT and AI for real-time monitoring and predictive maintenance. | Increased efficiency, reduced downtime, and enhanced operational safety. |

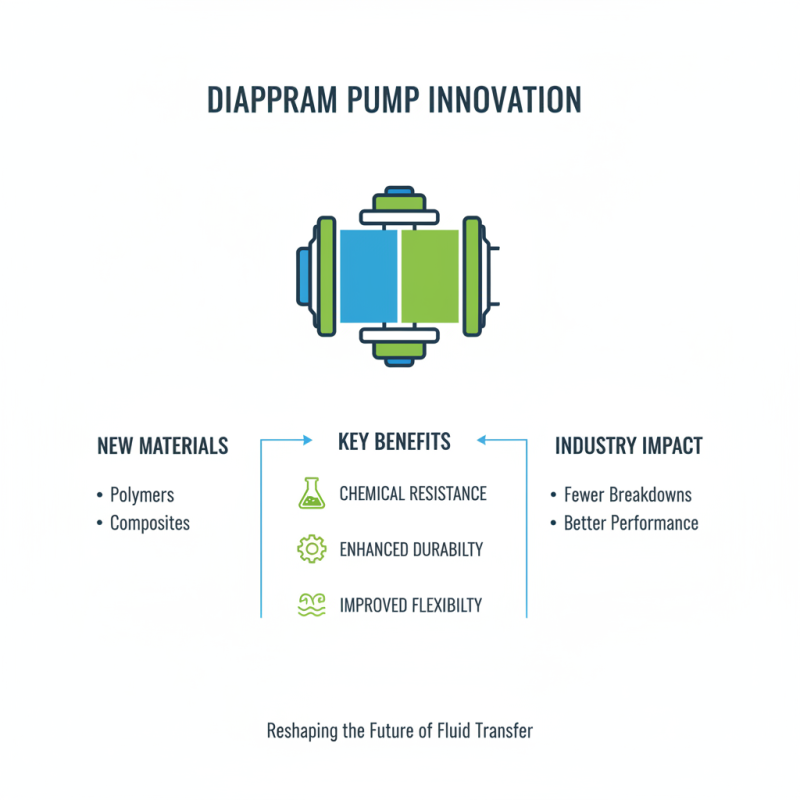

| Material Advancements | Use of advanced polymers and composites to improve chemical resistance and longevity. | Longer service life and reduced maintenance costs. |

| Energy Efficiency | Focus on reducing the energy consumption of pump systems. | Lower operational costs and reduced environmental impact. |

| Modular Design | Design innovations that allow for easy upgrades and customization. | Enhanced flexibility and adaptability in various applications. |

| Sustainability Initiatives | Focus on eco-friendly materials and processes in production. | Positive brand image and compliance with environmental regulations. |

Impact of Sustainability Standards on Diaphragm Pump Design and Usage

Sustainability is shaping the future of diaphragm pump design. Compliance with environmental standards is no longer optional. A recent report indicates that 70% of manufacturers prioritize eco-friendly practices. They focus on reducing energy consumption and minimizing waste. This shift enhances pump efficiency and performance.

In 2026, expect materials used in diaphragm pumps to evolve. Leading manufacturers are exploring biodegradable and recyclable materials. This creates a significant reduction in the environmental footprint. The market demand for such innovations is evident, with companies reporting a 30% increase in sustainable product requests.

**Tip:** Evaluate product certifications when choosing a diaphragm pump. Check if they meet the latest sustainability standards.

Design changes are also emerging. Pumps are now being designed for easier maintenance and longevity. This reduces the need for replacements and lowers overall resource use. Companies that adopt these practices report higher customer satisfaction and loyalty. Still, the journey to complete sustainability is ongoing.

**Tip:** Regularly assess your diaphragm pump's efficiency. Small improvements can lead to significant savings in energy and costs.

Market Growth Projections for Chemical Diaphragm Pumps: 2026 Forecast

The chemical diaphragm pump market is set to grow significantly by 2026. Several factors contribute to this growth. Industries are increasingly prioritizing safety and efficiency. This shift drives demand for technologically advanced pumps. These pumps minimize leaks and enhance reliability.

Tips: Regular maintenance is crucial. Ensure that diaphragm pumps are inspected often. This will help prevent unexpected breakdowns. Pay attention to wear and tear signs. Early detection can save costs.

The focus on sustainability is also shaping the market. Companies are looking for environmentally friendly options. There is a growing preference for materials that reduce environmental impact. However, some manufacturers struggle to adapt to these new standards. This requirement can create challenges in production and design.

Tips: Consider energy-efficient models. They can help lower operational costs. Analyze your current workflow to identify potential improvements. Investing in training for staff can enhance overall performance.

Emerging Materials in Diaphragm Pumps: Enhancing Performance and Safety

Emerging materials in diaphragm pumps are reshaping the industry. New polymers and composites are now available. These materials offer better chemical resistance. Enhanced durability means fewer breakdowns during operation. Improved flexibility allows for better performance under varying conditions.

Consider the benefits of lightweight materials. They reduce the overall weight of the pump. Lower weight can lead to easier installation and maintenance. However, lightweight does not always mean lower strength. It’s essential to choose wisely based on the application.

One tip is to keep an eye on advancements in nanotechnology. These materials can improve performance and safety. Testing new compounds can be costly. Yet, the investment may prove worthwhile over time. Another consideration is assessing how these materials perform under stress. Longevity is key, and some newer options may not deliver as promised. Evaluate options carefully before making changes to existing systems.

Integration of IoT and Smart Technology in Diaphragm Pump Operations

The integration of IoT and smart technology in diaphragm pump operations is reshaping the industry. By enabling real-time data monitoring, operators can optimize performance and enhance efficiency. Imagine sensors continuously collecting data on pressure, flow rate, and temperature. This information can be invaluable for predictive maintenance.

However, the implementation of these technologies is not without challenges. Connectivity issues might disrupt data transmission. Security concerns also arise with increased digital integration. Companies must invest in robust cybersecurity measures to protect their systems.

Moreover, not all facilities are ready for this transition. Some may struggle with the technology’s complexities. Training staff to understand and utilize these advancements can be daunting. Still, the potential benefits make this journey worthwhile. Embracing IoT in diaphragm pumps may well define the future of fluid management.

2026 Trends in Chemical Diaphragm Pumps: IoT and Smart Technology Integration

Related Posts

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

-

2026 How to Choose the Right Diaphragm Pump Diaphragm for Your Needs?

-

Why You Need a Laboratory Pump for Efficient Fluid Transfer

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Why Are Micro Pumps Essential for Modern Technology Applications?