Top 10 Direct Pumps: Key Features and Buying Guide for 2023

In the ever-evolving landscape of fluid transfer technology, direct pumps have become a cornerstone for various industries, ranging from agriculture to manufacturing. As these systems simplify the pumping process with their straightforward design, understanding their key features is essential for making informed purchasing decisions. Industry expert Dr. Emily Johnson, a leading authority on fluid dynamics, notes, "The efficiency and reliability of direct pumps are paramount for operations that depend on seamless fluid management." This insight underscores the importance of choosing the right direct pump in today’s competitive market.

As we delve into the top 10 direct pumps of 2023, we'll explore the defining characteristics that set these pumps apart, including flow rate, energy efficiency, and maintenance requirements. This guide aims to equip buyers with the knowledge necessary to select a direct pump that meets their specific needs, ensuring optimal performance and longevity. From their application in industrial settings to their role in residential use, understanding the core attributes of direct pumps is crucial for leveraging their full potential in various operations.

Top 10 Direct Pumps: Overview of Market Trends and Applications in 2023

The direct pump market is experiencing significant trends in 2023, primarily driven by advancements in technology and an increasing focus on energy efficiency. As industries prioritize sustainability, manufacturers are developing pumps that minimize energy consumption while maintaining optimal performance. Innovations such as variable frequency drives and smart sensors are becoming commonplace, allowing for real-time monitoring and enhanced control over pump operations. This transition not only reduces operational costs but also helps businesses meet environmental regulations more effectively.

Moreover, the applications of direct pumps are broadening across various sectors including agriculture, water treatment, and manufacturing. In agriculture, for instance, direct pumps are essential for irrigation systems, ensuring consistent water supply while optimizing resource usage. In water treatment facilities, these pumps are pivotal in managing the filtration and distribution processes, thus enhancing overall water quality. The versatility of direct pumps in such diverse environments illustrates their growing importance and adaptability in response to evolving market demands. As industries continue to integrate smart technologies, the role of direct pumps as a key component of efficient systems is set to expand further.

Key Features to Consider When Choosing Direct Pumps for Specific Needs

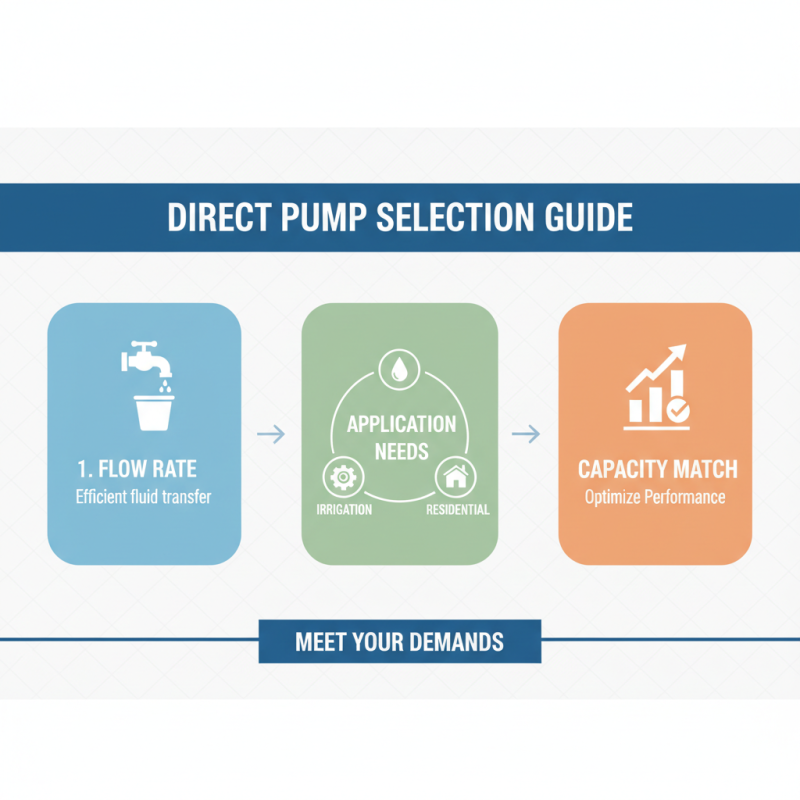

When selecting direct pumps, it's essential to consider several key features tailored to your specific needs. First, assess the flow rate, as this determines how efficiently the pump will move fluids. Different applications, such as irrigation, industrial processes, or residential uses, may require various flow rates. Understanding the required capacity will help narrow your choices to pumps that can meet your demands without over- or under-performing.

Another critical feature to evaluate is the pump's construction material. Depending on the fluid being pumped—whether it is corrosive, abrasive, or high-temperature—you may need materials such as stainless steel, plastic, or specialized alloys. The compatibility of the pump with the fluid ensures durability and longevity, reducing the risk of leaks and maintenance issues. Additionally, consider the pump's energy efficiency, as this not only affects operational costs but also contributes to environmental sustainability.

Lastly, it's important to think about the pump's ease of installation and maintenance. Look for designs that allow for straightforward setup and require minimal downtime for servicing. Features such as integrated monitoring systems or user-friendly interfaces can significantly enhance the user experience, making it easier to oversee the pump's performance and intervention when needed. By prioritizing these aspects, you can find a direct pump that effectively meets your unique requirements.

Comparative Analysis of Performance Metrics Across Leading Direct Pump Models

When selecting the best direct pumps for your needs, a comparative analysis of performance metrics is critical. Key features to consider include

flow rate,

pressure output,

energy efficiency,

and durability.

Evaluate each model’s specifications such as maximum head height and GPM (gallons per minute) ratings, ensuring they align with your intended application.

Reviewing user feedback can also provide insights into real-world performance and reliability, helping you make a more informed decision.

Tips for selecting the right direct pump include assessing your specific requirements and environment. For optimal efficiency, choose a model with adjustable settings that can adapt to varying workloads.

Additionally, consider maintenance requirements; a pump with easier access to parts can save you time and repair costs in the long run. Always check for warranties or customer service options,

as these factors play a crucial role in your investment's longevity.

Finally, conducting a side-by-side comparison of energy consumption can highlight which models not only perform well but also save costs in the long haul.

Pay attention to noise levels, especially if the pump will be situated in a noise-sensitive area. Taking these performance metrics into account will guide you toward the

direct pump that best fits your needs for 2023.

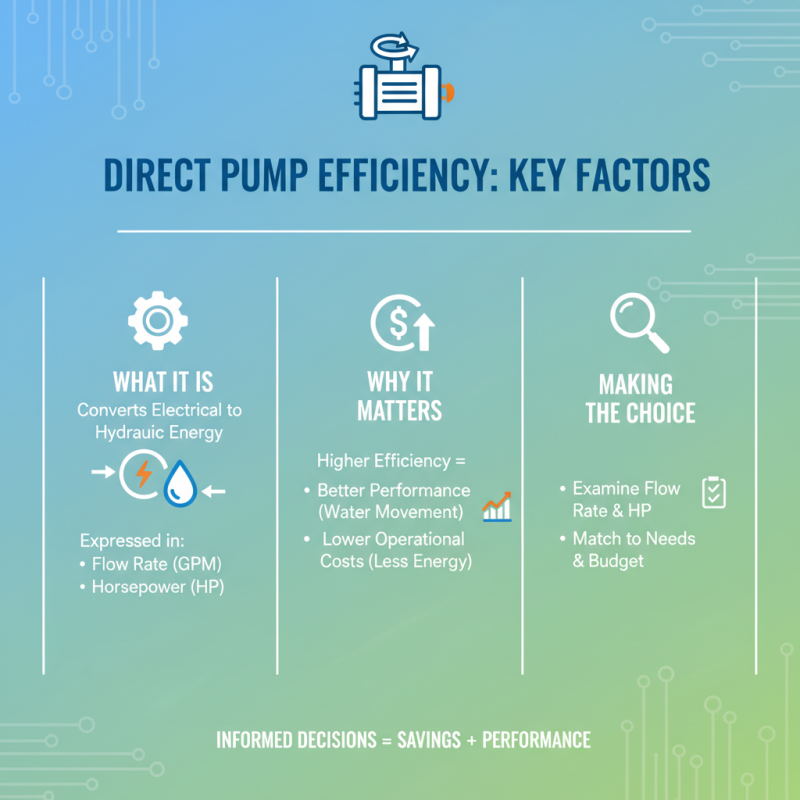

Understanding Direct Pump Efficiency Ratings and Their Impact on Cost

Understanding direct pump efficiency ratings is essential for making informed decisions, as these ratings can significantly influence both performance and overall cost. Efficiency ratings are typically expressed through metrics such as flow rate and horsepower, reflecting how effectively a pump converts electrical energy into hydraulic energy. A higher efficiency rating not only means better performance in terms of water movement but can also indicate lower operational costs, as these pumps can run with less energy consumption. When evaluating direct pumps, it’s crucial to examine these efficiency metrics closely to ensure the chosen model aligns with both specific needs and budget constraints.

Furthermore, the impact of pump efficiency on long-term operational costs cannot be overstated. A pump with a low efficiency rating may seem more affordable initially, but it can lead to increased energy bills and higher maintenance costs over time. In contrast, investing in a more efficient model may require a larger upfront investment, but the savings accrued from reduced energy consumption and fewer repairs make it a financially sound choice in the long run. Understanding the relationship between efficiency ratings and cost is therefore vital for consumers looking to optimize performance while managing their budgets effectively.

Essential Maintenance Tips for Prolonging the Lifespan of Direct Pumps

To ensure the longevity and efficient performance of direct pumps, regular maintenance is essential. One of the most critical maintenance tasks is routine inspection. Operators should check for signs of wear, leaks, and unusual noises during operation. Early detection of potential issues can prevent costly repairs and downtime. Additionally, monitoring the pump's electrical connections and ensuring they are secure can help maintain optimal functionality.

Another vital component of pump maintenance is proper lubrication. Depending on the pump's design, certain components may require periodic greasing or oiling to reduce friction and prevent overheating. It is essential to refer to the manufacturer’s guidelines to determine the appropriate type and frequency of lubrication. Furthermore, maintaining the cleanliness of the pump and its environment can prevent debris buildup that could impede performance. Regular cleaning schedules should be established to ensure that both internal and external components are free from dust and contaminants, ultimately enhancing the pump's operational efficiency.

Related Posts

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Top Tips for Choosing the Best Well and Pump Systems in 2025

-

Top 7 High Viscosity Pumps for Optimal Performance in Industrial Applications