2025 How to Pump Direct: Tips for Maximizing Your Output Efficiently

In today's competitive landscape, maximizing your output efficiently is essential for success, and one innovative approach to achieving this goal is through the method known as "pump direct." This technique harnesses the power of direct pumping to streamline operations, reduce waste, and enhance productivity. By integrating best practices for direct pumping into your workflow, you can unlock significant performance gains and improve overall efficiency.

In this guide, we will explore various tips and strategies that will help you effectively implement pump direct methods in your processes. Whether you are involved in industrial, agricultural, or any other fields where fluid movement is critical, understanding how to optimize your output through direct pumping can yield substantial benefits. From selecting the right equipment to maintaining optimal operational conditions, we will cover key aspects that can elevate your performance to new heights. Join us as we delve into the essentials of pump direct and discover how to maximize your output efficiently.

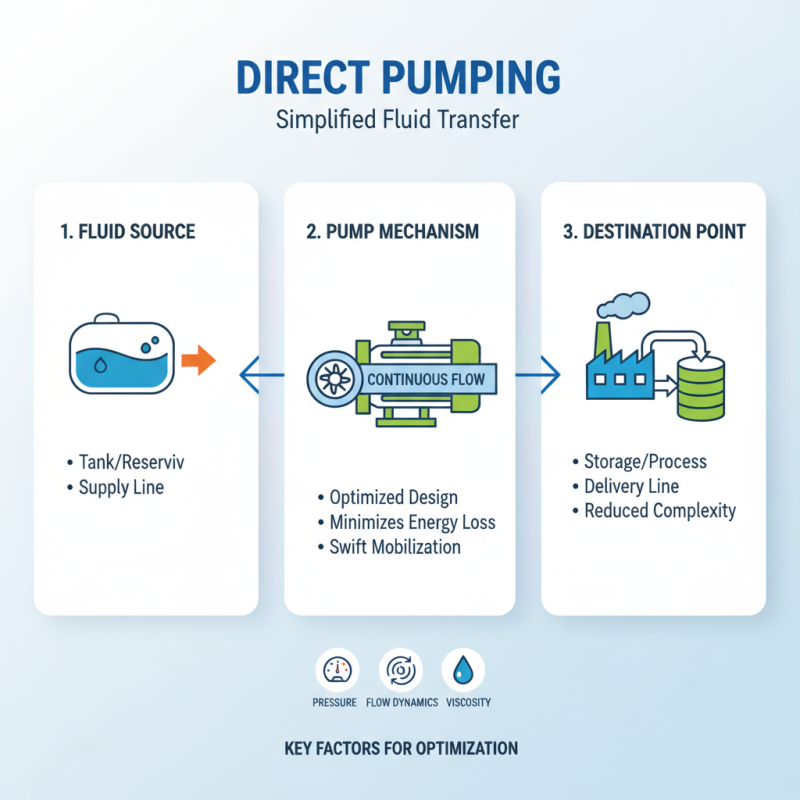

Understanding Direct Pumping: Key Principles and Concepts

Direct pumping involves a straightforward yet efficient method of transferring fluids from one location to another, minimizing the complexity often associated with traditional pumping systems. The fundamental principle of direct pumping is to create a continuous flow path where the fluid can be easily and swiftly mobilized. Understanding the flow dynamics, pressure requirements, and the viscosity of the fluid being pumped is crucial for optimizing performance. By ensuring that the pump’s design aligns with the specific needs of the application, unnecessary energy loss can be avoided, enhancing overall efficiency.

Key concepts in direct pumping include the importance of selecting the right pump configuration and maintaining proper alignment in the system. Factors such as the pump's head capacity, flow rate, and operational conditions must be evaluated to ensure optimal performance. Regular maintenance and monitoring can also significantly contribute to the longevity and reliability of direct pumping systems. By focusing on minimizing friction losses and ensuring that components are adequately sized for the application, operators can achieve a maximized output and improved efficiency in their pumping operations.

Essential Equipment for Efficient Direct Pumping Operations

Efficient direct pumping operations play a crucial role in various industries, particularly in maximizing output and reducing operational costs. Selecting the right equipment is essential for enhancing performance. According to the American Petroleum Institute (API), efficient pumping systems can increase production by up to 30% when upgraded with modern technology. Key components include variable frequency drives (VFDs), which allow for precise control of motor speeds, and advanced pump technologies designed to handle varying flow rates without sacrificing efficiency.

To maximize your direct pumping output, consider implementing the following tips: First, ensure regular maintenance of your pumping equipment. A study by the Hydraulic Institute indicates that routine maintenance can prevent up to 80% of mechanical failures. Second, utilize monitoring systems that provide real-time data on flow rates, pressure, and equipment performance. Integrating these systems can lead to more informed decision-making, ensuring your operation runs smoothly and effectively. Additionally, investing in modular pumping systems can offer flexibility and scalability, catering to diverse operational needs while keeping energy consumption low.

Furthermore, understand the significance of proper installation and alignment of pumping systems. Misaligned components can cause significant energy losses, with estimates suggesting up to 10% inefficiency due to poor alignment. By focusing on essential equipment and best practices, businesses can achieve substantial improvements in their direct pumping operations, ultimately driving profitability and sustainability.

2025 Direct Pumping Efficiency: Monthly Output Analysis

This chart represents the monthly output of a direct pumping operation over a six-month period. The data indicates how various factors like equipment efficiency, maintenance, and operational changes can impact overall output.

Strategies for Optimizing Pump Performance and Output

Optimizing pump performance and output is crucial for ensuring efficient operations in various industries. Understanding the fundamentals of pump performance helps in identifying areas for improvement. One key strategy is to regularly monitor the pump's operational parameters, such as flow rate, pressure, and energy consumption. This data provides insights into the pump's efficiency and helps pinpoint issues that may hinder performance.

Tips for maximizing pump output include performing routine maintenance to prevent wear and tear. Pump components should be checked regularly for leaks, blockages, and corrosion. Implementing automated monitoring systems can also enhance performance; these systems can provide real-time data and alerts for any irregularities, allowing for swift action before minor issues escalate into significant problems. Adjusting the pump's operating conditions to match its design specifications can further improve efficiency and longevity.

Lastly, consider the importance of proper installation and alignment. Misalignment can lead to increased wear and lower output. Therefore, taking the time to ensure that pumps are correctly aligned and installed at the outset will lead to long-term benefits and enhanced performance. By focusing on these strategies, you can ensure your pumping system operates at its best, maximizing both output and efficiency.

2025 How to Pump Direct: Tips for Maximizing Your Output Efficiently - Strategies for Optimizing Pump Performance and Output

| Parameter | Optimal Value | Current Performance | Improvement Suggestions |

|---|---|---|---|

| Flow Rate (GPM) | 150 | 120 | Regular Maintenance & Pipe Inspection |

| Pump Efficiency (%) | 85 | 75 | Upgrade Pump Components |

| Operating Temperature (°F) | 150 | 170 | Install Temperature Control System |

| Vibration Level (mm/s) | 0.5 | 1.2 | Balance Rotor & Check Mountings |

| Power Consumption (kW) | 20 | 25 | Assess Load Distribution |

Maintenance Practices to Enhance Pump Efficiency and Longevity

Maintaining pump efficiency is essential for ensuring optimal performance and extending the lifespan of your equipment. Regular inspections and maintenance practices play a crucial role in achieving this goal. Start by establishing a routine maintenance schedule that includes checking seals, bearings, and lubricants. Over time, these components can wear out or become contaminated, leading to decreased performance and potential failures. By proactively replacing worn parts and using the appropriate lubricants, operators can minimize wear and tear, thereby enhancing overall efficiency.

In addition to regular inspections, monitoring the operational conditions of the pump is vital. Keep an eye on parameters such as flow rates, pressure, and temperature, as deviations from the norm can indicate underlying issues that need to be addressed. It’s also important to maintain proper alignment to prevent unnecessary strain on the pump. Implementing vibration analysis can help detect alignment problems early, allowing for corrective actions that enhance both performance and longevity. Lastly, training staff on best operational practices and the importance of maintenance can lead to a more engaged workforce, ultimately contributing to the effective management and upkeep of pumping systems.

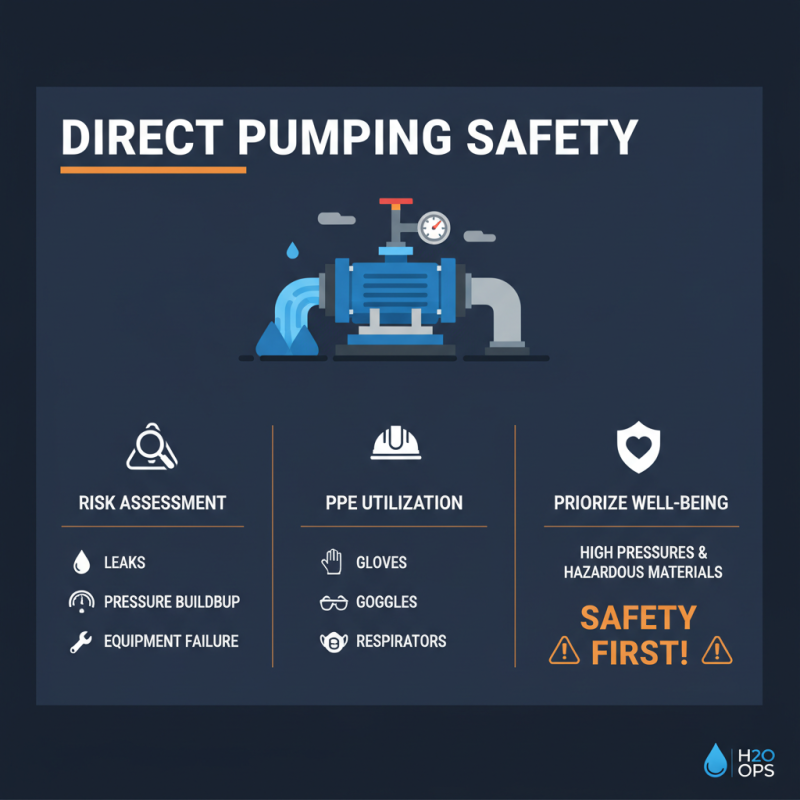

Safety Considerations in Direct Pumping Operations

When engaging in direct pumping operations, safety considerations are paramount. The nature of direct pumping often involves high pressures and the potential for hazardous materials, making it essential to prioritize the well-being of all personnel involved. Operators should conduct thorough risk assessments prior to beginning any pumping operations, identifying potential hazards such as leaks, pressure buildups, and equipment failures. Personal protective equipment (PPE) must be utilized appropriately, including gloves, goggles, and respirators, to mitigate exposure to harmful substances.

Regular maintenance of pumping equipment plays a crucial role in ensuring safety. Operators should adhere to scheduled inspections and servicing to identify any wear or malfunctioning components that could lead to accidents. Additionally, establishing clear operational protocols can help prevent mishaps. This includes setting up emergency shutdown procedures, clearly marking emergency exits, and providing comprehensive training for all personnel. By fostering a culture of safety awareness and ensuring that all staff are well-informed about the risks and safety measures, organizations can significantly reduce the likelihood of accidents during direct pumping operations.

Related Posts

-

Why You Need Effective Pump Solutions for Your Business Efficiency

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

Why Precision Pumps Are Essential for Precision Engineering Applications

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023