Why Precision Pumps Are Essential for Precision Engineering Applications

In the realm of precision engineering, the choice of equipment can significantly impact the quality and efficiency of production processes. Among the various components that facilitate precision engineering applications, precision pumps stand out as an indispensable tool. These pumps are designed to deliver fluids with unparalleled accuracy, which is critical in sectors such as pharmaceuticals, aerospace, and semiconductor manufacturing. According to a report by Grand View Research, the global precision pump market is expected to reach USD 4.57 billion by 2025, growing at a CAGR of 7.5%. This growth can be attributed to the increasing demand for high precision fluid handling in advanced manufacturing processes.

Precision pumps not only ensure better control over flow rates and pressures but also contribute to minimizing waste and enhancing product quality. In applications where even the slightest deviation can lead to catastrophic failures, the reliability of precision pumps becomes paramount. A comprehensive study by Market Research Future suggests that advancements in pump technologies are essential to meet the evolving needs of precision engineering, particularly as industries lean towards automation and smart manufacturing systems. Therefore, understanding how to integrate precision pumps effectively into engineering operations is crucial for achieving optimum performance and maintaining competitive advantage in the market.

The Critical Role of Precision Pumps in Modern Engineering Solutions

Precision pumps play a critical role in modern engineering solutions, serving as the backbone of various applications where accuracy and reliability are paramount. In industries such as pharmaceuticals, aerospace, and micro-manufacturing, the demand for precise fluid control translates into the necessity for high-performance pumping systems. These pumps are engineered to deliver exact flow rates and pressures, ensuring that processes are executed flawlessly, which is vital in maintaining quality and compliance standards.

Moreover, the adaptability of precision pumps allows them to meet the unique requirements of diverse engineering tasks. With advancements in technology, these pumps can now operate under varying conditions while maintaining optimal efficiency. They support intricate operations, such as those found in injection molding and chemical processing, where even the slightest deviation can lead to significant errors and costs. Thus, precision pumps not only enhance operational effectiveness but also bolster innovation within precision engineering by enabling the development of cutting-edge solutions tailored to specific needs.

Key Features of Precision Pumps That Enhance Engineering Applications

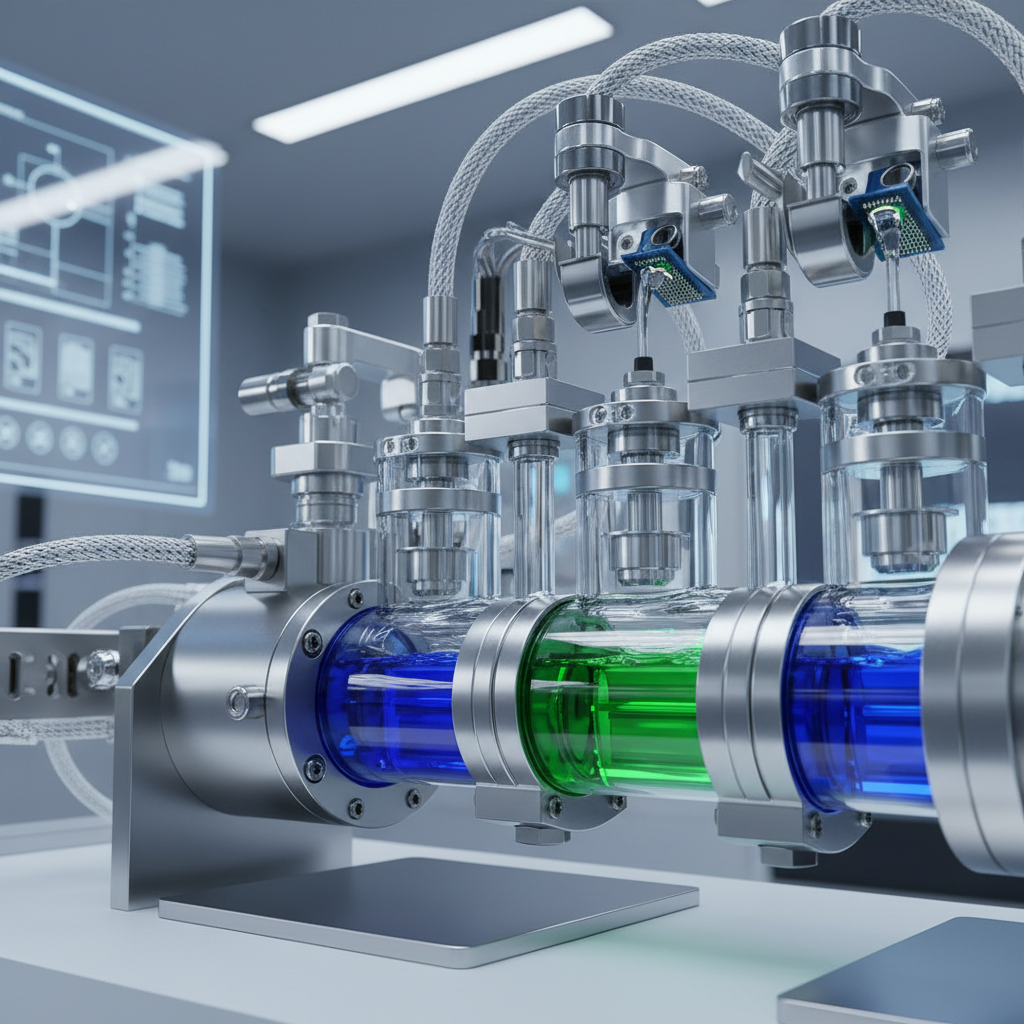

Precision pumps play a crucial role in various engineering applications, particularly where accuracy and reliability are paramount. One key feature of precision pumps is their ability to maintain consistent flow rates regardless of variations in pressure or viscosity. This stability is essential in environments where even minor fluctuations can lead to significant errors, ensuring that processes function smoothly and efficiently.

Another important characteristic of precision pumps is their high level of control over the delivery process. Many modern precision pumps are equipped with advanced technologies such as variable speed drives and digital metering systems, which allow for real-time adjustments to flow rates. This capability not only enhances the precision of the application but also minimizes waste and optimizes the use of resources. Additionally, the use of durable materials in the construction of these pumps ensures longevity and reliability, which are critical in demanding engineering scenarios.

Applications of Precision Pumps Across Various Engineering Sectors

Precision pumps play a pivotal role across various engineering sectors due to their ability to provide accurate and reliable fluid transfer. In the aerospace industry, for instance, precision pumps are crucial for fuel management systems, where even the slightest deviation can lead to catastrophic failures. A report by MarketsandMarkets indicates that the global aerospace pump market is expected to reach $1.45 billion by 2027, underscoring the demand for high-performance pumps that ensure safety and efficiency in aircraft operations.

In the healthcare sector, precision pumps facilitate the delivery of medications and fluids with exceptional accuracy. The increasing prevalence of chronic diseases has spurred a projected growth in the global infusion pump market, anticipated to reach $10.8 billion by 2025, as highlighted by Grand View Research. This growth reflects the reliance on precision pumps for applications such as intravenous therapy and chemotherapy, where dosage precision is vital for patient safety and treatment efficacy.

Moreover, in the chemical processing industry, precision pumps are essential for handling corrosive and viscous fluids. According to a report from Research and Markets, the chemical pumps market is expected to grow significantly, driven by advancements in pump technology that enable safer and more efficient fluid management. The incorporation of precision pumps ensures that these processes run smoothly, preventing leaks and minimizing waste, which is increasingly important in a world focused on sustainability.

The Impact of Precision Pump Technology on Product Quality and Efficiency

Precision pump technology plays a critical role in enhancing product quality across various engineering applications. These pumps are designed to deliver fluids at highly accurate flow rates and pressures, which is essential for processes that require stringent control. By minimizing fluctuations and providing consistent delivery, precision pumps ensure that the final products meet strict quality standards. For instance, in industries such as pharmaceuticals and electronics, even the smallest deviation in fluid measurement can lead to defective products or compromised performance. Thus, the reliability of precision pumps directly influences the overall quality of the end product.

In addition to improving product quality, precision pump technology significantly boosts efficiency in engineering processes. The accurate flow control allows for optimized use of materials, reducing waste and lowering operational costs. Furthermore, precise measurements facilitate automated systems that enhance production speed and consistency. This efficiency is particularly vital in competitive markets where time and resource management are critical. As industries continue to evolve, the integration of advanced precision pump technology becomes increasingly essential, driving innovation and productivity in precision engineering applications.

Future Trends in Precision Pump Development for Engineering Excellence

In the realm of precision engineering, the demand for high-efficiency precision pumps is rapidly evolving. According to a report by the Global Precision Pump Market Insights, the market is projected to grow from $3.5 billion in 2022 to over $5 billion by 2027, showcasing a compound annual growth rate (CAGR) of 7.5%. This growth underscores the increasing reliance on precision pumps in critical applications such as medical devices, aerospace, and micro-manufacturing. The integration of advanced materials and smart controls in pump design is expected to enhance operational efficiency and reduce energy consumption by up to 20%, aligning with the industry's push for sustainability.

Looking toward the future, the development of precision pumps is set to focus on incorporating IoT technology for real-time monitoring and optimization. These innovations are anticipated to not only improve reliability but also to foster predictive maintenance strategies, thus minimizing downtime. A study by Research and Markets indicated that nearly 30% of manufacturers plan to adopt intelligent pumping solutions by 2025, highlighting a shift towards automated precision in engineering processes. As engineers continue to seek excellence in design and functionality, precision pumps will play a pivotal role in meeting these evolving needs.

Related Posts

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance