What is a Precision Pump and How Does it Work in Various Applications

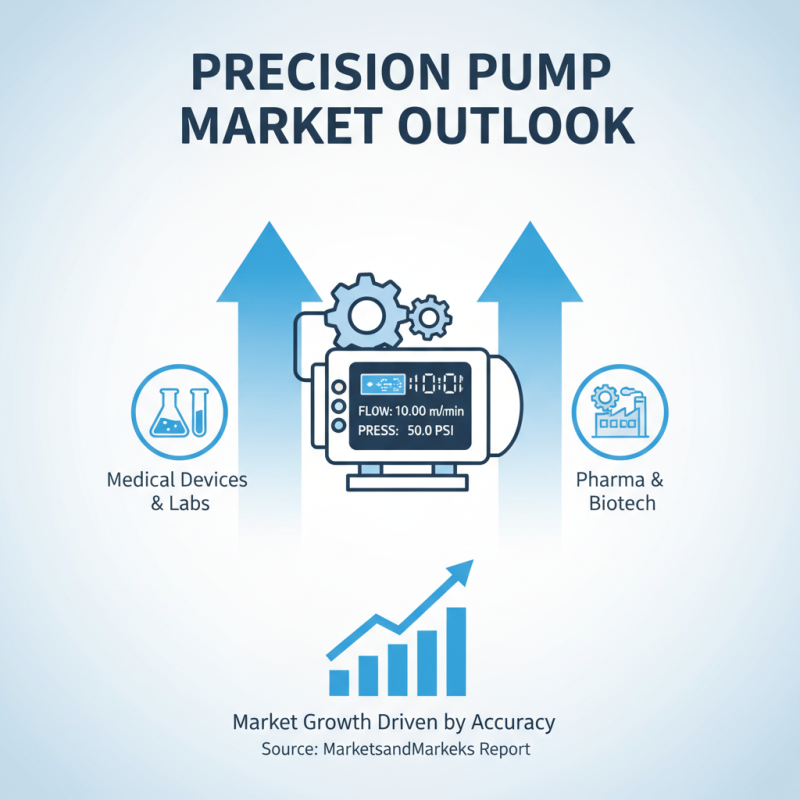

Precision pumps play a critical role in various industrial applications, from pharmaceuticals to petrochemicals, where accurate fluid delivery is paramount. The global precision pump market is projected to reach $5 billion by 2027, driven by advancements in technology and increasing demand for high-performance pumping solutions. According to a report by MarketsandMarkets, the growth of sectors such as medical device manufacturing and water treatment is further fueling the demand for precision pumps, highlighting their significance in ensuring operational efficiency and product quality.

Dr. Emily Johnson, a leading expert in fluid dynamics, underscores the importance of precision pumps by stating, “The accuracy of fluid handling not only enhances productivity but also ensures compliance with stringent industry regulations.” This emphasizes the critical role that precision pumps play in maintaining standards across various sectors. As industries become increasingly automated and interconnected, the demand for precision pumps that can deliver reliability and efficiency will continue to rise, showcasing their indispensable nature in modern applications.

In summary, precision pumps are integral to ensuring the exactness of fluid movement, which is essential for a myriad of applications across diverse industries. Their ability to adapt to various conditions and requirements positions them as vital components in the evolution of manufacturing and process management, further solidifying their place in the competitive industrial landscape.

What is a Precision Pump? Definition and Overview of Functionality

A precision pump is a specialized device designed to deliver fluids at a consistent flow rate and pressure with high accuracy. These pumps are essential across various industries, including pharmaceuticals, biotechnology, and chemical processing, where exact measurements are crucial. According to a report by MarketsandMarkets, the precision pump market is expected to grow significantly, driven by the increasing demand for accurate fluid handling in medical devices and laboratory applications.

The functionality of precision pumps hinges on their ability to minimize fluctuations in flow rates and pressures. They often utilize advanced technologies such as positive displacement, peristaltic, or diaphragm mechanisms to achieve this goal. For instance, positive displacement pumps can move precise volumes of fluid with each cycle, making them ideal for applications where the exact dosage is critical. A study published in the Journal of Pharmaceutical Sciences highlighted that using precision pumps in drug formulation processes can reduce variability by up to 15%, underscoring their importance in ensuring product quality and compliance with regulatory standards.

Key Components of Precision Pumps and Their Roles in Operations

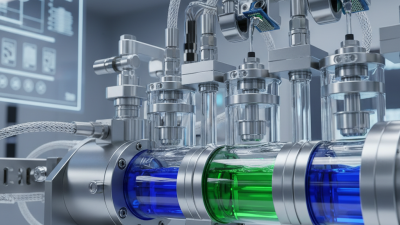

Precision pumps are essential components in various industries where accurate fluid movement is critical. The key components of precision pumps include the pump head, diaphragm, motor, and control system. Each of these parts plays a vital role in ensuring optimal performance. The pump head is where the fluid enters and is pressurized; its design affects the flow rate and pressure stability. The diaphragm, often made of flexible material, separates the pump chamber from the motor, allowing for controlled pumping action without contamination.

The motor powers the pump, determining its speed and efficiency. Furthermore, the control system is instrumental in regulating flow rates and responding to varying operational demands. Advanced control systems can integrate sensors and feedback mechanisms, enabling precise adjustments based on real-time data. Together, these components ensure that precision pumps operate smoothly across applications such as pharmaceuticals, chemical processing, and laboratory settings, allowing for consistent and reliable fluid handling.

Applications of Precision Pumps in the Pharmaceutical Industry

Precision pumps play a crucial role in the pharmaceutical industry, where accuracy in fluid handling is essential. These pumps are designed to deliver precise volumes of liquids at consistent flow rates, which is vital for various processes such as formulation, dosing, and packaging. By ensuring that the right amount of active pharmaceutical ingredients (APIs) is used, precision pumps help to maintain the integrity of drug formulations and comply with stringent regulatory standards.

In applications such as lab-scale research and large-scale production, precision pumps facilitate accurate mixing and dosing of components. For instance, in the manufacturing of sterile products, maintaining a precise flow rate prevents contamination and guarantees the required concentration of ingredients. Additionally, in the biopharmaceutical sector, these pumps are used for filling vials and syringes, where any deviation from the set parameters can compromise patient safety. Overall, the reliability and accuracy of precision pumps are indispensable for the efficient and safe production of pharmaceutical products.

Applications of Precision Pumps in the Pharmaceutical Industry

Impact of Precision Pumps on Water Treatment Processes and Efficiency

Precision pumps play a crucial role in enhancing water treatment processes by ensuring accurate flow rates and consistent performance. These pumps are designed to move precise volumes of fluids, making them ideal for applications that demand reliability and efficiency. In water treatment facilities, precision pumps enable the accurate dosing of chemicals needed for coagulation, disinfection, and pH adjustment. This not only optimizes the treatment process but also minimizes the risk of chemical overuse, which can lead to environmental concerns.

Moreover, the impact of precision pumps extends to improving overall efficiency in water treatment systems. By maintaining defined flow rates, these pumps contribute to reduced energy consumption and operational costs. Their ability to function effectively under varying conditions ensures that water treatment facilities can adapt to changes in demand without compromising quality. This adaptability leads to more sustainable practices, ultimately ensuring a safer and cleaner water supply for communities. Additionally, the integration of modern precision pumping technologies supports real-time monitoring and automation, further enhancing operational excellence in water treatment processes.

Emerging Technologies in Precision Pump Design and Their Advancements

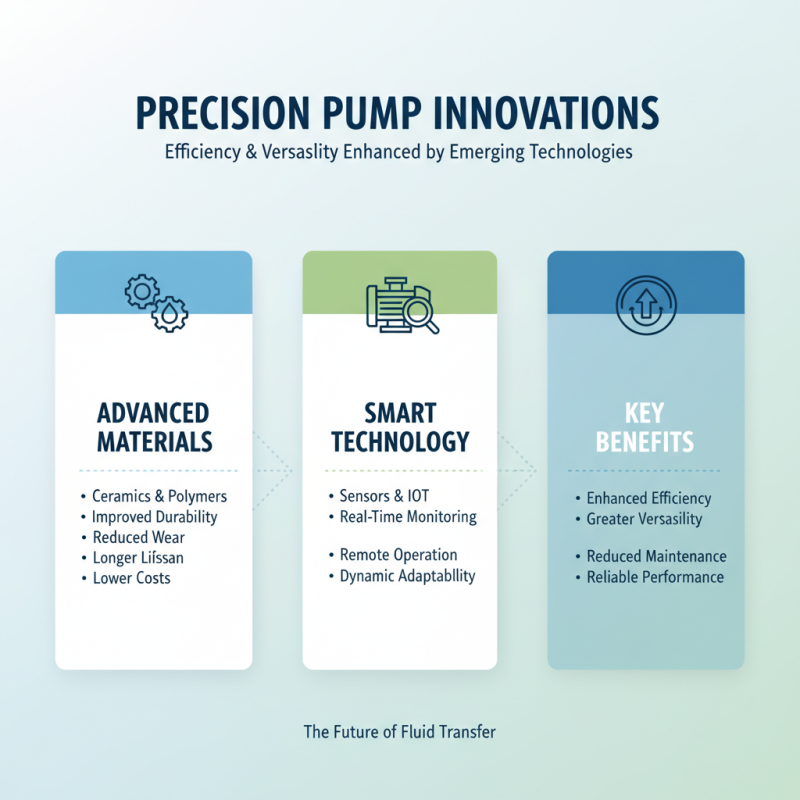

Emerging technologies in precision pump design have significantly enhanced their efficiency and versatility across various applications. Advanced materials, such as ceramics and polymers, have been integrated to improve durability and reduce wear, leading to longer operational life and lower maintenance costs. Additionally, the advent of smart technology has allowed for the incorporation of sensors and IoT capabilities that enable real-time monitoring and remote operation, making precision pumps more responsive to dynamic operational conditions.

Moreover, developments in software algorithms have facilitated better control mechanisms for precision pumps. These advancements enable precise flow regulation and adaptive operation based on real-time data analytics, which ensures optimal performance in critical applications like pharmaceuticals and biotechnology. As these technologies continue to evolve, the potential for precision pumps to contribute to energy-saving efforts and sustainability initiatives becomes increasingly prominent, underscoring their importance in both industrial and environmental contexts.

Related Posts

-

Why Precision Pumps Are Essential for Precision Engineering Applications

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

The Future of Battery Pumps Revolutionizing Efficiency in Power Tools

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications