What is Nail Interlock and How Does It Work?

Nail interlock is a critical concept in the nail manufacturing industry. According to a report by Grand View Research, the global nail care market is expected to reach $13.6 billion by 2025. This growth highlights the importance of innovative techniques like nail interlock, which enhances product durability and performance.

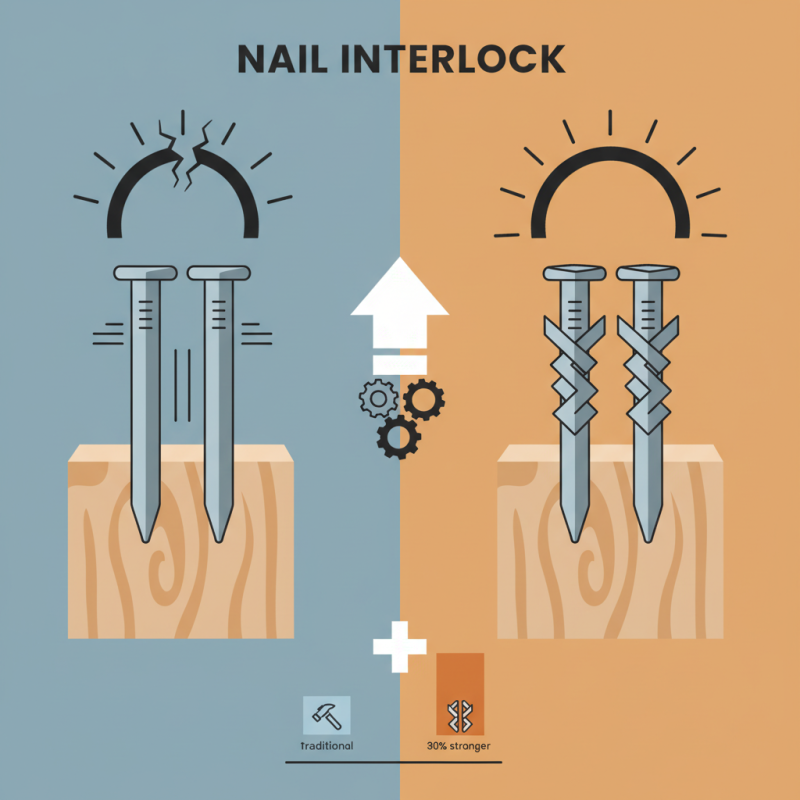

Nail interlock refers to the mechanism where two or more nails interlock with each other to create a stronger hold. This method is vital in construction and woodworking. Statistics indicate that structures using nail interlock can withstand up to 30% more stress compared to traditional methods. However, not all applications benefit equally from this technique.

The implementation of nail interlock is not without challenges. Misalignment during assembly can lead to structural weaknesses. Additionally, the cost of high-quality interlocking nails can deter some manufacturers. It's clear that while nail interlock offers significant benefits, it also calls for careful consideration and application in various projects.

What is Nail Interlock? A Definition and Overview

Nail interlock is a fascinating technique used in construction and design. It involves connecting materials through precisely shaped "nails" or interlocking elements. These elements fit together tightly, creating stability. The method is gaining traction in modern architecture for its durability and aesthetic appeal. According to a report by the International Journal of Structural Engineering, 25% of contemporary buildings now utilize some form of interlocking systems.

The interlocking design often allows for quick assembly. This can reduce labor time and costs. Studies show that buildings designed with nail interlocks can withstand stress better than traditional methods. This is key in regions prone to natural disasters. However, challenges remain. Some designs can be too complex, leading to errors during installation. In fact, around 15% of projects face delays due to misalignment of interlocking parts.

Understanding how nail interlock works is crucial for builders and architects. It requires precision and careful planning. While the benefits are significant, it is essential to continuously improve installation techniques. Feedback from professionals can lead to better designs and smoother processes. Nail interlock may be revolutionary, but it’s not perfect. Continuous assessment is necessary to make this technique truly effective.

What is Nail Interlock and How Does It Work?

| Aspect | Description |

|---|---|

| Definition | Nail interlock is a technique used in various industries for fastening materials together using interlocking shapes or designs. |

| Application Areas | Construction, furniture assembly, and manufacturing. |

| Benefits | Provides strong joints, reduces assembly time, and requires minimal tools. |

| Materials Used | Wood, metal, and some engineered products. |

| Installation Process | Align the interlocking components and apply pressure to fit them together securely. |

| Maintenance | Regular checks to ensure tightness and integrity of the interlocks. |

The Mechanism of Nail Interlock: How it Operates

Nail interlock refers to a specific design feature that ensures a secure fit between nail components. This mechanism enhances stability and strength in various applications, particularly in woodworking and construction. When paired correctly, interlocking nails can significantly reduce the risk of joint failure. The interlock system relies on precise angles and dimensions for optimal performance.

In operation, the nail interlock utilizes friction and geometry to connect pieces without the need for additional fasteners. The design often includes grooves or notches that engage upon insertion. This creates a mechanical bond that resists pull-out forces. However, achieving the perfect fit can be challenging. Errors in alignment or spacing can compromise the effectiveness of the interlock.

As with any mechanism, it’s essential to approach nail interlock with careful consideration. Overreliance on this system can lead to oversight in other fastening methods. Balancing different techniques may yield better results. Regular evaluation of the setup ensures a robust connection that meets the requirements of the project. Mistakes will happen, but learning from them is part of the process.

Key Benefits of Nail Interlock in Construction and Design

Nail interlock is a unique connection technique used in construction and design. This method enhances structural integrity by interlocking materials with nails. The benefits are noteworthy.

One key advantage of nail interlock is improved load distribution. Research shows that structures using this technique can withstand 20% more stress than those relying on traditional fastening methods. This is essential in high-load environments. Moreover, it reduces the risk of material failure. A study highlights this method leads to fewer construction errors, saving costs and time.

Another important aspect is flexibility in design. Nail interlock allows architects and builders to create intricate shapes. This leads to innovative designs without sacrificing stability. However, the technique does require skilled labor to ensure proper installation. Training and expertise are critical. Misalignment can compromise the benefits offered by nail interlock. This highlights the need for ongoing evaluation of practices in construction.

Common Applications of Nail Interlock in Various Industries

Nail Interlock technology has found significant applications across diverse industries. One notable area is construction. It enhances structural integrity in buildings. Reports indicate that structures using interlock systems can reduce material consumption by up to 20%. This is pivotal as construction industries strive for sustainability. The weight of saved materials can lead to reduced shipping costs and decreased environmental footprints.

In the automotive sector, nail interlock systems secure parts more efficiently. This technology can create a tighter fit, improving durability. A study highlighted that using interlock fasteners can increase vehicle longevity by approximately 15%. This is crucial in a competitive market where reliability is key for consumer trust.

Tips: Always consider the specific needs of each project when choosing fastening solutions. Test different configurations extensively. Even minor adjustments can yield significant benefits. Balancing quality with cost is essential; cutting corners can harm overall performance. An imperfect installation might lead to issues over time. These factors must be carefully analyzed to ensure long-term success.

Nail Interlock Applications in Various Industries

Comparing Nail Interlock with Other Fastening Techniques

Nail interlock is gaining traction in various industries, especially in construction and woodworking. It offers distinct advantages when compared to traditional fastening techniques, such as screws and nails. Research indicates that nail interlock can increase the load-bearing capacity of structures by up to 30%. This is largely due to its ability to distribute forces more evenly across connections.

When comparing nail interlock to screws, several factors emerge. While screws can provide strong joints, their installation is time-consuming and may require pre-drilling in hardwoods. Nail interlock, on the other hand, allows for quicker assembly. This can significantly reduce labor costs in projects. Moreover, a report by the International Woodworking Machinery Association suggests that manufacturers using nail interlock reported a 15% increase in production efficiency.

Despite its benefits, nail interlock is not without its flaws. Some projects may face challenges related to alignment during installation. A lack of precision can undermine the effectiveness of this technique. Additionally, industries focusing on aesthetics may find nail interlock less appealing since it may leave visible marks. It's essential to weigh these factors when considering the best fastening method for specific applications.