Why Are Micro Pumps Essential for Modern Technology Applications?

Micro pumps have become a cornerstone of modern technology. These tiny devices play a vital role in various applications. From medical devices to automotive systems, their demand is skyrocketing. According to a recent market analysis, the micro pump market is projected to reach $6.4 billion by 2025. This significant growth reflects their versatility and importance.

In medical sectors, micro pumps are used for precise drug delivery. Devices like insulin pumps rely on these mechanisms for accuracy. Reports indicate that over 30 million people in the U.S. use devices that incorporate micro pumps. The automotive industry has also embraced this technology for fluid management systems, enhancing vehicle efficiency.

Despite their advantages, challenges persist. Manufacturing complexity and high initial costs can hinder widespread adoption. It remains essential for stakeholders to address these issues. Ensuring reliability and affordability will be crucial for the future of micro pumps. As we push forward, their role will only expand in technology, making it vital to understand their impact.

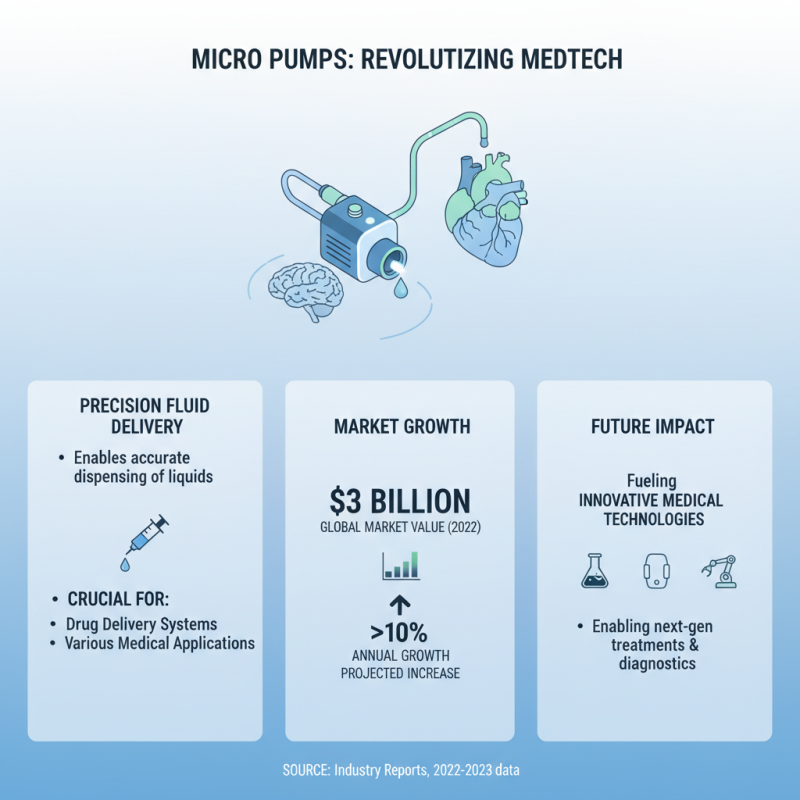

The Role of Micro Pumps in Advancing Medical Technology

Micro pumps have revolutionized the field of medical technology. These tiny devices enable precise fluid delivery, which is crucial for various applications, including drug delivery systems. In 2022 alone, the global micro pump market was valued at approximately $3 billion. It is projected to grow by over 10% annually. This growth indicates that more innovative medical technologies will rely on micro pumps.

The role of micro pumps extends to various medical devices, such as insulin pumps and wearable monitors. These devices improve patient compliance and outcomes. With miniaturization, micro pumps are now more efficient. They allow for better control of dosages, which is essential in treatments where precision is key. For example, a study revealed that 80% of patients prefer automated drug delivery over traditional methods due to its accuracy.

Tip: Consider using micro pumps when designing new medical devices. Their small size and reliability can enhance usability and patient experience.

Despite their advantages, challenges persist. Some micro pumps face issues with clogging or air bubbles, which can affect performance. Ongoing research aims to address these limitations. Streamlining design and improving materials can lead to better efficiency and longevity.

Tip: Keep an eye on new materials in micro pump development. Advances here may open doors to more durable and efficient designs.

Applications of Micro Pumps in Industrial Processes

Micro pumps play a crucial role in various industrial processes. These small devices manage the precise flow of liquids and gases. Their compact size allows integration into tight spaces. Micro pumps are vital in the pharmaceutical industry. They ensure accurate dosing in drug delivery systems. This precision directly impacts treatment effectiveness.

In food processing, micro pumps enhance ingredient dispensing. They enable consistent flavor profiles and quality control. However, challenges remain. Some processes face limitations in pump lifespan. Regular maintenance is essential to avoid failures. In research labs, micro pumps assist in experiments requiring exact measurements. Scientists rely on them for reliable results.

Innovation continues to push the boundaries of micro pump technology. There are new materials and designs emerging. Yet, the market may be slow to adopt them. This hesitation can stall advancements. Addressing these challenges will be necessary for future applications. As industries evolve, the demand for efficient micro pumps will only increase.

Micro Pumps: Key Components in Biotechnology Innovations

Micro pumps have become vital in biotechnology, driving innovations that impact healthcare and research. These miniature devices precisely control fluid movement, enabling applications in drug delivery, diagnostics, and regenerative medicine. According to recent reports by industry experts, the micro pump market is projected to reach $1.8 billion by 2025, reflecting a significant Compound Annual Growth Rate (CAGR) of 12.1%.

In biotechnology, micro pumps ensure accurate dispensing of small fluid volumes. For example, they help deliver medications at micro-liter levels, which enhances treatment effectiveness. This precision is crucial in enabling personalized medicine. A study found that 70% of patients benefit from dosage tailored to their unique needs. However, despite these advances, some micro pump designs struggle with scalability. As demands increase, manufacturers face challenges in maintaining precision without compromising efficiency.

Applications in diagnostics are also notable. Micro pumps facilitate on-site testing by enabling rapid sample analysis. This trend promises to revolutionize monitoring diseases. Reports suggest that 40% of diagnostic tests will be conducted outside laboratories by 2027. Yet, ensuring reliability remains a challenge. Variations in fluid viscosity can impact performance. Continuous research is essential to refine these tools and enhance their functionality. The journey ahead involves overcoming hurdles while harnessing the potential of micro pumps in biotechnological breakthroughs.

Micro Pumps in Biotechnology Innovations

Challenges and Solutions in Micro Pump Technology Development

Micro pumps have become crucial in various modern technology applications, including medical devices and automotive systems. However, their development faces notable challenges. One primary issue is the miniaturization of components while maintaining functionality. Engineers often struggle to balance size and performance. Achieving high precision at small scales demands advanced techniques and materials.

The materials used in micro pumps can also present problems. Many traditional materials may not perform well under diverse conditions, such as extreme temperatures or corrosive environments. Finding suitable alternatives that are durable and efficient continues to be a challenge. Additionally, cost factors play a significant role in the choice of materials. Many high-performing options are often prohibitively expensive.

Another challenge lies in integration with existing systems. Micro pumps need to communicate effectively with other components. Misalignment or compatibility issues can lead to failures. Testing and refining designs can be time-consuming and costly. Engineers often find themselves revisiting initial concepts, struggling to improve performance while keeping tabs on costs. Balancing these various factors requires careful consideration and innovative thinking.

Why Are Micro Pumps Essential for Modern Technology Applications? - Challenges and Solutions in Micro Pump Technology Development

| Application | Micro Pump Type | Key Challenges | Solutions/Technologies | Future Trends |

|---|---|---|---|---|

| Medical Devices | Peristaltic Pumps | Accuracy in fluid delivery | Advanced sensors for real-time feedback | Miniaturization and portability |

| Automotive | Diaphragm Pumps | Temperature resistance | Use of heat-resistant materials | Increased efficiency and sustainability |

| Aerospace | Piezoelectric Pumps | Weight constraints | Lightweight composite materials | Smart monitoring systems |

| Consumer Electronics | Electromagnetic Pumps | Miniaturization | Integration with micro-electronics | Enhanced functionality and features |

Future Trends in Micro Pump Applications and Design

Micro pumps are gaining traction in various modern technology applications. Their small size and precise control make them indispensable. As industries shift towards miniaturization, micro pumps align perfectly with this trend. They power everything from medical devices to advanced cooling systems. Their integration enhances efficiency and adaptability.

Looking ahead, the design of micro pumps continues to evolve. New materials and technologies enable higher performance. Future micro pumps may use smart technology for real-time adjustments. This could revolutionize fields like drug delivery and environmental monitoring.

Yet, challenges remain in balancing efficiency with cost. Designers must think critically about these aspects.

Emerging trends suggest a focus on sustainability and energy efficiency. As environmental concerns grow, optimizing micro pump designs becomes crucial. The need for durability and less waste is pressing. Innovators may have to rethink traditional designs.

It’s an ongoing process, requiring creativity and adaptability. Some designs may not be perfect, sparking continuous improvement.

Related Posts

-

How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

How to Choose the Right Battery Pump for Your Needs in 2025

-

Top 7 High Viscosity Pumps for Optimal Performance in Industrial Applications

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

What is a Water Pump and How Does it Work Explained Simply