2026 How to Choose the Right Diaphragm Pump Diaphragm for Your Needs?

Choosing the right diaphragm pump diaphragm can be a daunting task. The diaphragm pump industry is rapidly evolving. In 2021, the global diaphragm pump market was valued at approximately $3.5 billion. Experts predict it will grow significantly by 2026.

According to John Smith, a renowned expert in the diaphragm pump sector, "Selecting the right diaphragm is critical for optimal performance." His insight highlights the importance of understanding specific application requirements. Each diaphragm has unique characteristics that determine suitability for different fluids and pressures.

Considering aspects like material compatibility and pressure range is essential. Many users often overlook these factors. As the industry matures, businesses face increasing demands for efficiency and safety. Proper selection of diaphragm pump diaphragms not only enhances performance but also minimizes risks of failure. Balancing cost and quality is a constant challenge in the selection process.

Understanding Diaphragm Pumps: Basic Principles and Functionality

Diaphragm pumps are essential in various industries due to their versatility and reliability. These pumps use a flexible diaphragm to create a pumping action. When the diaphragm moves, it displaces fluid. This simple yet effective mechanism allows for the transfer of a wide range of fluids, including slurries and viscous materials.

A key advantage of diaphragm pumps is their ability to handle different pressures and flow rates. Data shows that they can achieve flow rates from 0.5 to 125 gallons per minute. This variability makes them suitable for diverse applications, from chemical processing to food production. However, improper selection can lead to inefficiencies. Understanding the specific requirements of your application is crucial.

Moreover, diaphragm pumps require regular maintenance. Many users overlook this aspect, which can reduce performance over time. An industry report indicated that nearly 30% of pump failures are due to lack of maintenance. It is important to evaluate your operational needs and assess the environmental conditions. Factors like temperature and fluid viscosity significantly impact pump performance.

Types of Diaphragm Pumps: Selecting the Best Option for Your Application

When choosing a diaphragm pump, understanding the various types is crucial. There are two main categories:

air-operated and electrically powered pumps.

Air-operated pumps are widely used in industries like wastewater treatment and food processing. They often excel in handling

abrasive and corrosive fluids. Reports show that these pumps can handle up to 90% of industrial fluid transfer needs.

On the other hand, electrically powered diaphragm pumps provide more efficiency for applications requiring precise flow control.

They are commonly used in laboratories and chemical industries. Studies indicate that they offer precise flow rates with less than 1% variation,

which is essential in many sensitive processes. However, these pumps might require more maintenance compared to

air-operated types.

It's also important to consider the materials used in diaphragm construction. Common options include

rubber, PTFE, and thermoplastic materials. Each offers

different benefits and drawbacks, affecting durability and chemical compatibility. Some users overlook this aspect, leading to increased maintenance costs.

Every application is unique, and understanding these differences can lead to better decision-making.

Key Features to Consider When Choosing a Diaphragm Pump

When selecting a diaphragm pump, consider key features that fit your needs. The material of the diaphragm is crucial. It dictates chemical compatibility and resistance to wear. Common materials include rubber and PTFE. Each has its own strengths and weaknesses. Assess the fluids you will pump. Will they corrode the materials?

Flow rate matters significantly. It determines how quickly the pump can transfer liquids. A high flow rate is essential for large volumes. However, it may not be necessary for smaller tasks. Evaluate your requirements closely.

Noise levels also deserve attention. Some pumps operate quietly, while others can be quite loud. If noise is a concern for your workspace, make this factor a priority.

Finally, think about maintenance. Some pumps are easier to service than others. Frequency of use impacts wear and tear. Underestimating this could lead to operational issues later. Often, users overlook the importance of these features. Remember to weigh the pros and cons of each option. By doing so, you’ll make a more informed choice.

Assessing Material Compatibility for Your Diaphragm Pump Needs

Choosing the right diaphragm pump diaphragm starts with material compatibility. Different applications require specific materials to ensure efficiency and longevity. Common materials include rubber, PTFE, and Nitrile. According to industry reports, selecting the wrong material can lead to failure and increased costs.

For instance, in a study by the Pump Industry Journal, 40% of diaphragm pump failures stemmed from material incompatibility. Pumps handling harsh chemicals need diaphragms made of specialized compounds. The right material protects against corrosion and wear. It’s essential to evaluate the chemical properties and temperature ranges of the fluids involved.

Environmental factors also play a crucial role. Diaphragms may encounter extreme temperatures, pressures, and abrasive substances. Adapting to these conditions is vital. Keep in mind that even slight discrepancies in compatibility can affect pump performance. The pursuit of the perfect material is ongoing. Each application is unique and requires diligent assessment.

2026 How to Choose the Right Diaphragm Pump Diaphragm for Your Needs? - Assessing Material Compatibility for Your Diaphragm Pump Needs

| Material | Compatibility | Temperature Resistance (°C) | Application Type |

|---|---|---|---|

| Nitrile (Buna-N) | Oil and Fuel | -20 to 80 | Industrial Applications |

| Viton | Chemical Resistance | -10 to 200 | Chemical Processing |

| EPDM | Water and Steam | -40 to 120 | Food Processing |

| PTFE | Non-Stick Properties | -200 to 260 | Pharmaceuticals |

| Silicone | Food Safe | -60 to 200 | Food & Beverage |

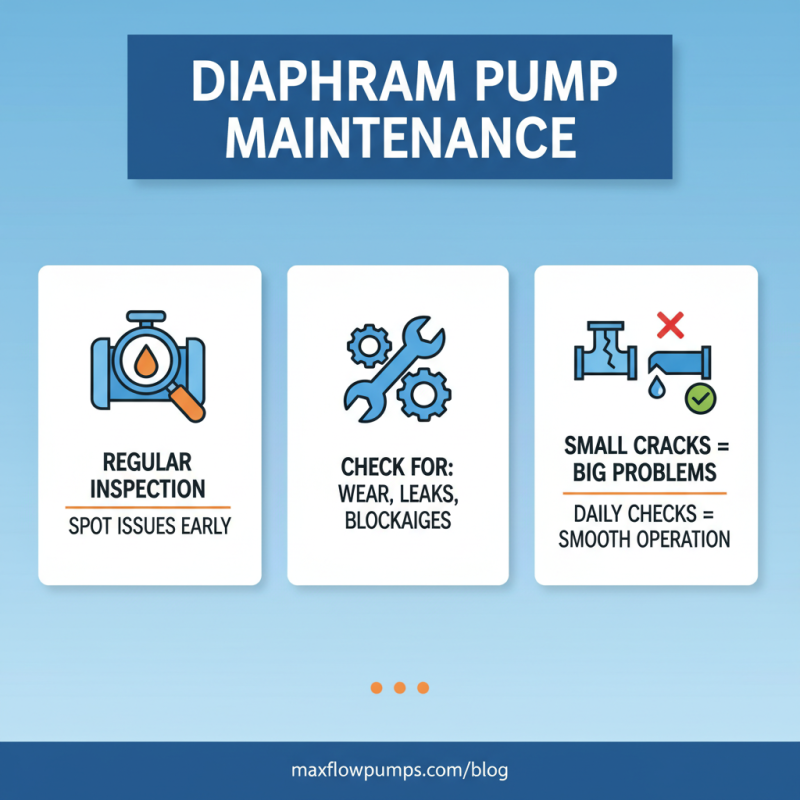

Maintenance and Durability: Ensuring Optimal Performance of Your Pump

Maintaining a diaphragm pump is crucial for its performance. Regular inspection helps spot issues early. Look for wear, leaks, and blockages. A small, unnoticed crack can lead to major problems. Daily checks ensure that your pump works smoothly.

Cleaning the pump is essential. Debris can accumulate and affect functionality. Take the time to disassemble and clean it thoroughly. Use appropriate cleaning agents that won’t damage the diaphragm. However, incorrect cleaning can sometimes worsen the issue. Be careful during this process; always follow guidelines.

Durability depends on the materials used and how you operate the pump. Harsh environments can take a toll. Ensure that you choose the right diaphragm material for your application. Evaluate if your current choice is indeed optimal. Sometimes, reassessing your decisions opens doors to better options.

Related Posts

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

2025 Top Lab Pump Innovations for Precision and Efficiency in Research

-

10 Best Pump Systems for Efficient Water Management in 2023

-

Why You Need Effective Pump Solutions for Your Business Efficiency