Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry

In today’s industrial landscape, efficient fluid handling is paramount, especially when dealing with high viscosity fluids that demand specialized equipment for optimal operation. High viscosity pumps are crucial for a variety of applications, ranging from food processing to heavy manufacturing, where the movement of thick, viscous materials can pose significant challenges. According to a recent report by the Fluid Handling Association, the global high viscosity pump market is projected to grow at a CAGR of 5.2% from 2023 to 2030, highlighting the increasing reliance on these essential tools in various industries.

Renowned expert Dr. John S. Thompson, a leading authority in fluid dynamics, emphasizes the importance of selecting the right equipment, stating, “The evolution of high viscosity pump technology has allowed industries to enhance productivity and ensure smoother operations by accurately handling challenging fluids.” As companies strive for greater efficiency and reduced operational costs, understanding the top high viscosity pumps available on the market becomes crucial. This article will delve into the top 10 high viscosity pumps, their features, and how they contribute to effective fluid management in industrial applications.

Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry

The market for high viscosity pumps, particularly magnetic drive pumps and progressing cavity pumps, is rapidly evolving. By 2024, the global magnetic pump market is projected to reach $700 million, with an anticipated growth to $960 million by 2033, reflecting a compound annual growth rate (CAGR) of approximately 3.6%. This trend indicates a growing demand for efficient fluid handling solutions in various industries, driven by the need for advanced technology in process management.

When selecting a high viscosity pump, it’s essential to understand the specific requirements of your application. Different pumps cater to diverse fluid characteristics, flow rates, and operating pressures. For instance, when dealing with extremely viscous fluids, opting for a pump with higher GPM ratings (over 1000) can enhance efficiency and minimize operational downtime.

Tips for optimizing pump performance include regular maintenance to ensure operational efficiency and monitoring the viscosity changes in fluids that may affect pump performance. Additionally, collaborating with knowledgeable suppliers can help identify the best pump solutions tailored to your specific industry needs.

Overview of High Viscosity Pumping Applications and Market Demand

The demand for high viscosity pumps has been steadily increasing across various industrial applications, driven by the need for efficient fluid handling solutions. The global high viscosity pump market has been characterized by significant growth, with predictions indicating a compound annual growth rate (CAGR) of around 6.0% from 2025 to 2035. This surge is largely attributed to the expanding sectors of oil and gas, food and beverage, and pharmaceuticals, all of which require the transportation of thick, viscous fluids.

Recent studies confirm that types of pumps such as positive displacement pumps and progressive cavity pumps are becoming increasingly favored due to their efficiency in handling high viscosity materials. For instance, the global market for progressive cavity pumps alone is expected to surpass USD 8.74 billion by 2025, showcasing robust demand fueled by advancements in technology and the growing emphasis on sustainable practices. As industries continue to innovate and optimize their processes, the high viscosity pump sector is poised to play a critical role in meeting operational demands efficiently.

Criteria for Selecting High Viscosity Pumps: Performance and Efficiency Standards

When selecting high viscosity pumps, it is essential to consider performance and efficiency standards that align with industry needs. According to the Hydraulic Institute, the efficiency of a pumping system can significantly impact operational costs, with inefficient pumps responsible for up to 20-30% of energy waste in industrial applications. High viscosity fluids, such as polymers, gels, and slurries, require specialized pumps designed to maintain flow without clogging or causing damage. Therefore, performance metrics such as flow rate, pressure capability, and shear sensitivity should be evaluated to ensure optimal handling of these challenging materials.

Moreover, the American Petroleum Institute emphasizes the importance of selecting pumps based on their capability to manage high viscosity fluids under varying temperatures and shear conditions. Selecting the right material compatibility is also critical, as it can affect the pump's lifespan and maintenance costs. Reports indicate that using pumps specifically designed for high viscosity applications can reduce maintenance downtime by up to 50%, leading to increased productivity. Additionally, energy-efficient models can cut energy consumption by as much as 15%, contributing to both cost savings and environmental sustainability in industrial settings.

Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry

| Pump Model | Maximum Viscosity (cP) | Flow Rate (L/min) | Efficiency (% | Power Requirement (kW) |

|---|---|---|---|---|

| Model A | 5000 | 50 | 85 | 2.5 |

| Model B | 3000 | 70 | 90 | 3.0 |

| Model C | 4500 | 65 | 88 | 2.8 |

| Model D | 6000 | 40 | 86 | 2.2 |

| Model E | 8000 | 30 | 87 | 4.0 |

| Model F | 3500 | 55 | 92 | 2.7 |

| Model G | 7000 | 35 | 84 | 3.5 |

| Model H | 9000 | 20 | 80 | 4.5 |

| Model I | 2500 | 80 | 89 | 2.0 |

| Model J | 4000 | 60 | 91 | 3.1 |

Comparison of Leading High Viscosity Pump Types and Their Applications

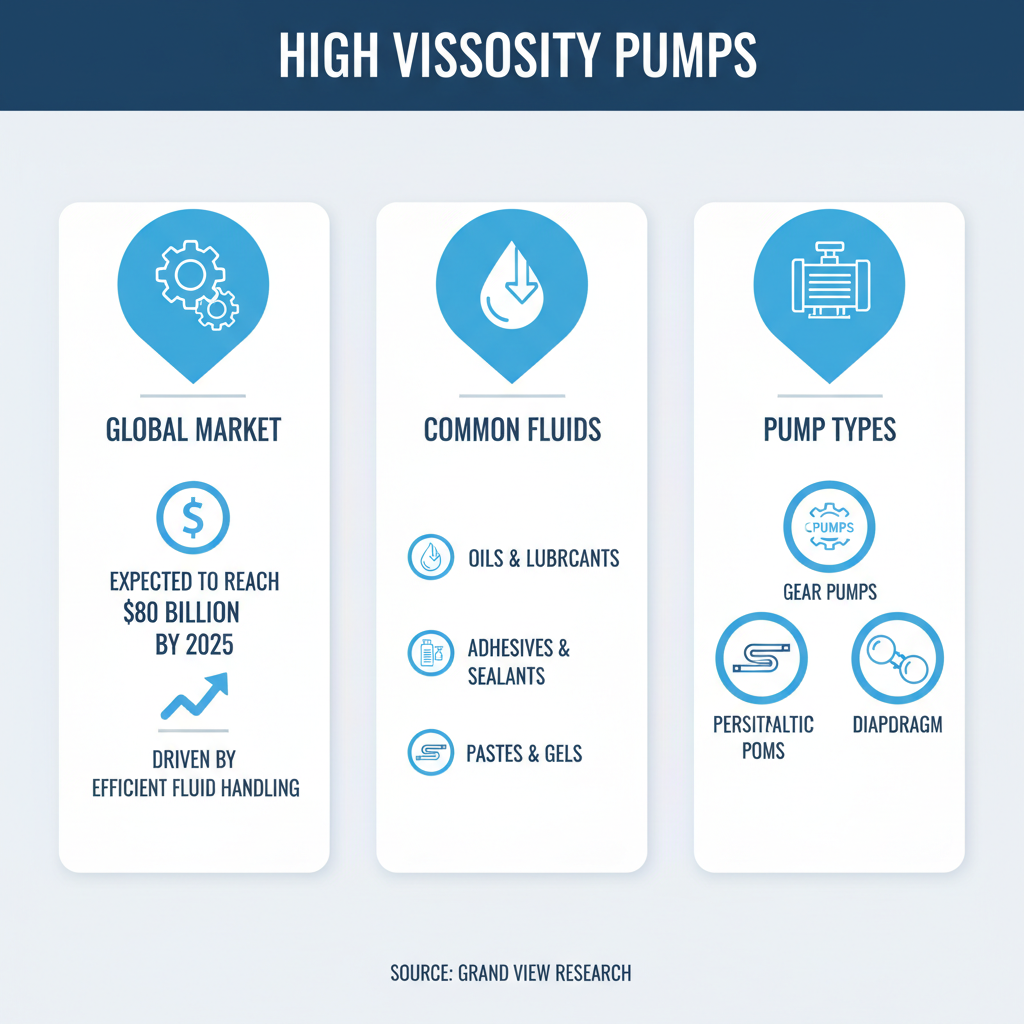

High viscosity pumps play a crucial role in industries that deal with thick fluids such as oils, adhesives, and pastes. According to a recent report by Grand View Research, the global market for industrial pumps is expected to reach $80 billion by 2025, driven in part by the demand for efficient fluid handling systems. Common pump types include gear pumps, peristaltic pumps, and diaphragm pumps, each suited for specific applications depending on the viscosity and nature of the fluid being transported.

Gear pumps are particularly effective for high viscosity fluids, as they can generate substantial pressure and maintain a steady flow rate. A study published by the Journal of Advanced Manufacturing Technology indicates that these pumps can handle fluids with viscosities up to 50,000 centipoise, making them ideal for applications in the chemical and food processing industries. On the other hand, peristaltic pumps are favored for their ability to pump shear-sensitive fluids without causing damage, making them essential in industries such as pharmaceuticals. As the demand for high viscosity fluid handling increases, understanding the strengths and limitations of each pump type becomes essential for optimizing operational efficiency.

Case Studies: Success Stories in High Viscosity Fluid Management

In the realm of industrial fluid management, efficiently handling high viscosity fluids is a considerable challenge. This is particularly evident when analyzing case studies that highlight the successes in this area.

For instance, a leading food processing company adopted high viscosity pumps to streamline their operations involving viscous sauces. These pumps, engineered for robust performance, not only improved the consistency of the final product but also reduced downtime by 30%, demonstrating the critical role that technology plays in fluid handling.

Moreover, the medical field presents innovative approaches to managing high viscosity substances, particularly in pediatric care. A recent case study illustrated the successful administration of ibuprofen suspensions through enteral feeding tubes (EFTs), highlighting the importance of viscosity in medication delivery for children with swallowing difficulties. Research indicates that specialized high viscosity pumps have the potential to optimize the delivery of such formulations, ensuring that pediatric patients receive accurate dosages efficiently.

These instances underscore the imperative for industries to adopt advanced pumping solutions that enhance fluid management while addressing specific viscosity challenges.

Conclusion

The article "Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry" provides a comprehensive overview of high viscosity pump applications and the increasing market demand for effective fluid management solutions. It emphasizes the importance of selecting the right high viscosity pump by outlining performance and efficiency standards that are critical for optimal operation.

The discussion includes a comparison of the leading types of high viscosity pumps, highlighting their applications across various industries. Additionally, the article features case studies that showcase successful implementations of high viscosity fluid management systems, illustrating the real-world benefits of these technologies. Finally, it touches on future trends and innovations in high viscosity pump technology, underscoring the ongoing evolution and adaptation within the industry to meet new challenges.

Related Posts

-

Top 7 High Viscosity Pumps for Optimal Performance in Industrial Applications

-

The Future of Battery Pumps Revolutionizing Efficiency in Power Tools

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency

-

2025 Top Lab Pump Innovations for Precision and Efficiency in Research

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide