Why You Need a Fluid Transfer Pump for Efficient Liquid Handling

In the modern industrial landscape, efficient liquid handling is paramount, and among the most indispensable tools for achieving this is the fluid transfer pump. As noted by Dr. Emily Carter, a leading expert in fluid dynamics and the design of pumping systems, "The choice of a fluid transfer pump can significantly impact operational efficiency and the safety of handling liquids across various applications." This underscores the critical role that fluid transfer pumps play in optimizing processes, ensuring that liquids are moved swiftly and securely from one location to another.

Fluid transfer pumps are designed to minimize waste and enhance productivity, making them essential in industries ranging from chemical manufacturing to food processing. Their ability to operate with precision allows for careful handling of a wide array of liquids, which is vital for maintaining quality and preventing spills. With a growing emphasis on sustainability and resource management, employing a reliable fluid transfer pump not only elevates workflow efficiency but also aligns with eco-friendly practices by reducing the chances of contamination and loss. Thus, understanding the importance of fluid transfer pumps is crucial for any organization looking to improve its liquid handling processes.

Understanding the Basics of Fluid Transfer Pumps

Fluid transfer pumps are essential tools in a variety of industries, facilitating the efficient handling and movement of liquids. These pumps are designed to transfer fluids from one location to another with minimal risk of spillage or contamination, making them a critical component in sectors such as agriculture, pharmaceuticals, and chemical processing. According to recent industry reports, the global fluid transfer pump market is projected to grow at a compound annual growth rate (CAGR) of approximately 6.5% from 2021 to 2026, highlighting the increasing demand for reliable liquid handling systems.

Understanding the fundamentals of fluid transfer pumps can significantly influence operational efficiency. These pumps operate on various principles, including positive displacement and centrifugal force, each suited for different applications. For instance, positive displacement pumps excel in moving viscous fluids, while centrifugal pumps are preferred for low-viscosity liquids. A study by the Fluid Power Society indicates that selecting the appropriate pump type can enhance energy efficiency by up to 30%, underscoring the importance of understanding pump mechanics and application scenarios. Ensuring the right pump is used not only improves the efficiency of the transfer process but also extends equipment life and reduces maintenance costs, which are crucial for long-term operational success.

Fluid Transfer Pump Efficiency Comparison

This chart illustrates the efficiency ratings of various types of fluid transfer pumps. Understanding these ratings can help you select the most suitable pump for your liquid handling needs.

Key Benefits of Using Fluid Transfer Pumps in Liquid Handling

Fluid transfer pumps play a crucial role in efficient liquid handling across various industries, including pharmaceuticals, food and beverage, and chemical processing. One of the key benefits of using these pumps is their ability to significantly reduce transfer times. According to a report by the International Fluid Power Society, companies utilizing fluid transfer pumps reported up to a 40% increase in operational efficiency due to faster pumping rates. This efficiency not only improves productivity but also minimizes the risks associated with manual handling of hazardous liquids.

Additionally, fluid transfer pumps provide enhanced safety measures and reduce the risk of spills and contamination. With advanced sealing technologies and automated systems, these pumps are designed to handle a wide range of liquids without leakage. Research by the Occupational Safety and Health Administration indicates that improved liquid handling practices can lead to a 30% decrease in workplace accidents related to spills and exposure. By investing in fluid transfer pumps, businesses can not only safeguard their employees but also comply with stringent regulatory standards.

**Tip:** When selecting a fluid transfer pump, consider the viscosity and chemical properties of the liquids to ensure optimal performance and compatibility.

**Tip:** Regular maintenance of fluid transfer pumps is essential. Schedule routine checks to mitigate potential issues and prolong the lifespan of the equipment.

Why You Need a Fluid Transfer Pump for Efficient Liquid Handling - Key Benefits of Using Fluid Transfer Pumps in Liquid Handling

| Feature | Description | Benefits |

|---|---|---|

| Efficiency | Designed for rapid liquid transfer. | Reduces time and labor costs in operations. |

| Versatility | Can handle various types of liquids. | Suitable for multiple applications across industries. |

| Safety | Minimizes spills and reduces manual handling. | Enhances workplace safety and compliance. |

| Cost-Effectiveness | Lower operating costs than traditional methods. | Increases overall profitability of operations. |

| Ease of Use | Simple setup and operation. | Reduces training time for staff. |

Different Types of Fluid Transfer Pumps and Their Applications

Fluid transfer pumps play an essential role in efficient liquid handling across various industries. There is a diverse range of fluid transfer pumps, including centrifugal pumps, diaphragm pumps, and gear pumps, each designed for specific applications. Centrifugal pumps are widely used for moving fluids in large volumes, making them ideal for water treatment and chemical processing. Diaphragm pumps, on the other hand, are perfect for transferring viscous fluids or materials with solids, commonly found in food processing and pharmaceuticals. Gear pumps are known for their precision and are primarily utilized in applications requiring a consistent flow of high-viscosity liquids.

When selecting the right fluid transfer pump, it is crucial to consider the nature of the liquid being handled, the required flow rate, and the system pressure. Tips for optimizing fluid transfer efficiency include regularly maintaining your pump to prevent wear and tear, ensuring all connections are secure to avoid leaks, and matching the pump type to the specific application for maximum performance. Additionally, employing proper safety measures while handling liquids can minimize risks associated with spills and exposure.

Overall, understanding the different types of fluid transfer pumps and their respective applications can significantly enhance operational efficiency and reliability in liquid handling processes, ensuring a seamless workflow across various sectors.

Best Practices for Choosing and Maintaining Fluid Transfer Pumps

When selecting a fluid transfer pump, it is crucial to consider several factors that ensure optimal performance and longevity. First, assess the specific requirements of your fluid handling tasks, including the viscosity, temperature, and chemical compatibility of the liquids involved. Different pumps are designed to handle varying fluid characteristics, so understanding these parameters will guide you to the appropriate type, whether it's centrifugal, diaphragm, or peristaltic pumps.

Regular maintenance is equally vital to the efficient operation of fluid transfer pumps. Implementing a routine inspection schedule can help you identify wear and tear before it leads to costly repairs or downtime. Cleaning the pump and ensuring all seals and fittings are intact can extend its lifespan significantly. Additionally, keeping the operating environment clear of debris and contaminants will minimize potential damage and ensure smooth operation. By prioritizing these best practices in selecting and maintaining fluid transfer pumps, you can enhance your liquid handling processes and improve overall efficiency.

Safety Considerations When Using Fluid Transfer Pumps

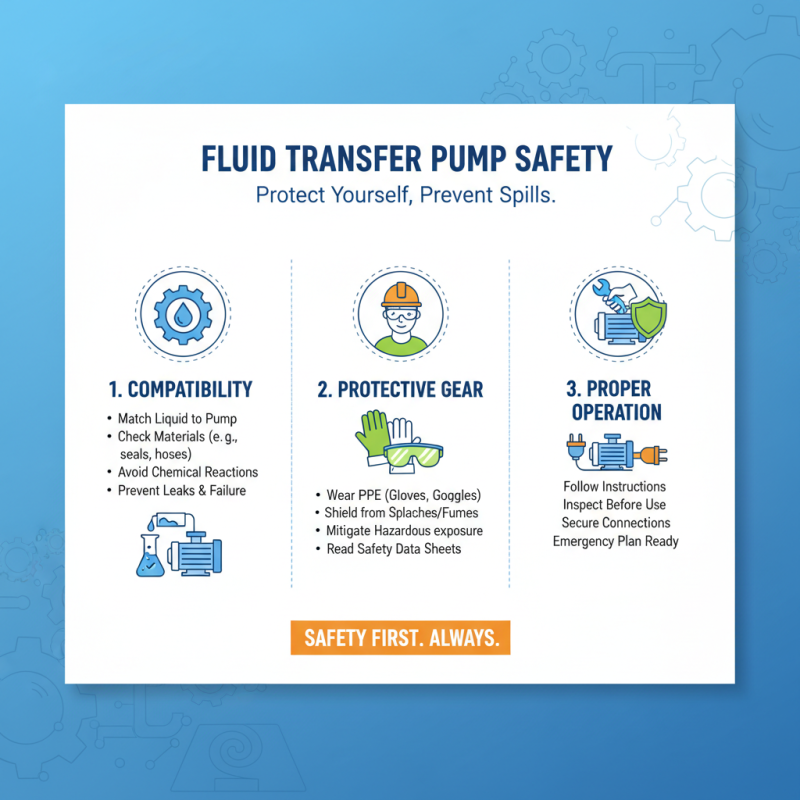

When using fluid transfer pumps, safety should always be a paramount consideration. These devices, while designed to facilitate the movement of liquids with efficiency and precision, can pose risks if proper precautions are not taken. Always ensure that the pump is compatible with the specific liquid being handled, as different substances may react adversely with certain materials, leading to leaks or pump failure. Additionally, wearing appropriate personal protective equipment (PPE) is crucial when operating these pumps to mitigate exposure to hazardous materials.

Another essential safety measure involves regular maintenance and inspections of the fluid transfer pump. Check for any signs of wear and tear, leaks, or other potential issues that could compromise safety during operation. It is also important to train staff members on safe operating procedures and emergency response protocols. In the event of a spill or malfunction, having a well-rehearsed plan can minimize risks and ensure a swift response, protecting both personnel and the environment. Adhering to these safety practices not only enhances operational efficiency but also fosters a safer workplace.

Related Posts

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

Top Benefits of Using Chemical Injection Pumps in Industrial Applications

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences