Why Fluid Pumps Are Essential for Efficient Industrial Operations?

Fluid pumps play a crucial role in enhancing industrial operations. According to a report by Research and Markets, the global fluid pump market is projected to reach $83 billion by 2026. This growth highlights their importance in various industries, including manufacturing, oil and gas, and pharmaceuticals.

An expert in fluid dynamics, Dr. Emily Tran, emphasizes, "Efficient fluid management is paramount for operational success." Her insight underscores the need for reliable fluid pumps. These systems help manage liquids, ensuring consistent flow and pressure. However, the industry faces challenges. Many companies still rely on outdated pump technology, leading to inefficiencies.

Regular maintenance is also often overlooked. This neglect can result in unexpected downtime and increased operational costs. By addressing these issues, companies can improve their processes. Better fluid management through advanced pumps can lead to significant improvements in productivity and cost-effectiveness.

Fluid Pumps: An Overview of Their Role in Industry

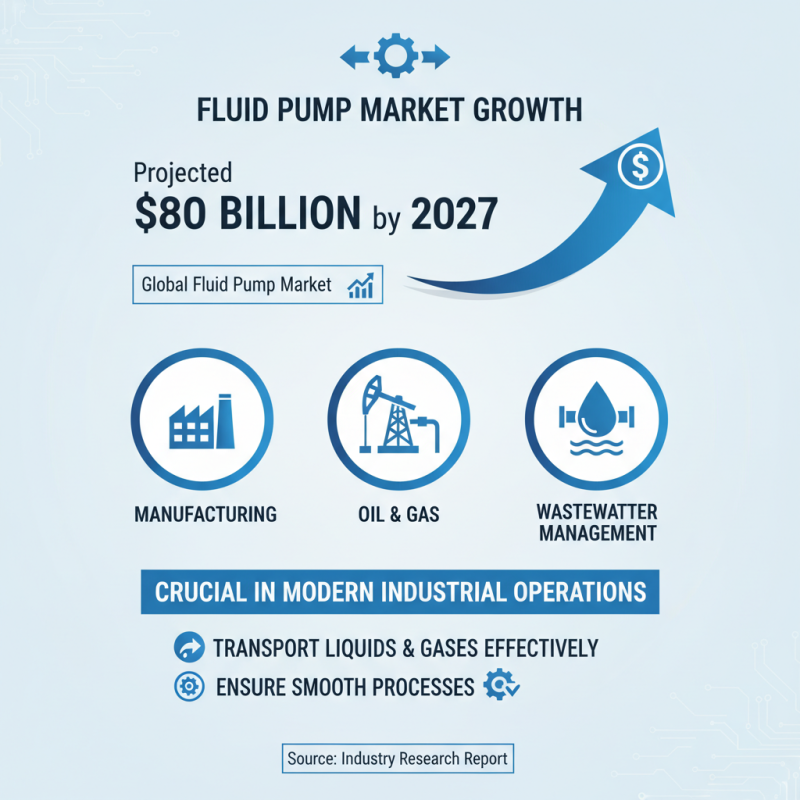

Fluid pumps are crucial in modern industrial operations. They transport liquids and gases effectively, ensuring processes run smoothly. According to a report from Industry Research, the global market for fluid pumps is projected to reach $80 billion by 2027. This highlights their importance across several sectors like manufacturing, oil and gas, and wastewater management.

In manufacturing, fluid pumps facilitate the movement of chemicals and solutions. These systems can impact production efficiency directly. For instance, a delay in pump operation can halt an entire assembly line. Data shows that inefficient pumping systems can lead to up to 20% energy loss. This loss emphasizes the need for consistent maintenance and evaluation.

Fluid pumps also play a vital role in ensuring safety. Faulty pumps can lead to hazardous spills, posing risks to workers and the environment. The chemical industry alone reports significant safety incidents related to pump failures annually. Therefore, addressing these flaws must be a priority for sustainable operational success and safety in workplaces.

Types of Fluid Pumps Used in Industrial Settings

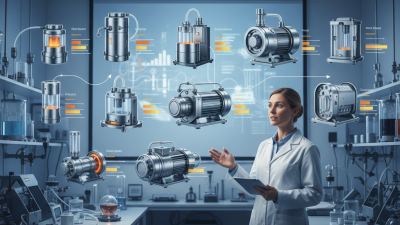

Fluid pumps play a crucial role in various industrial operations. Different types serve specific functions, ensuring efficiency in processes. Centrifugal pumps are popular for their ability to move large volumes of fluid quickly. They work well with low-viscosity liquids and are essential in applications like water supply and chemical processing.

Positive displacement pumps offer another option. These pumps are ideal for viscous fluids or when precise delivery is necessary. They trap a fixed amount of fluid and force it into the discharge pipe. This feature makes them advantageous in food production or oil transfer.

**Tips:** Regular maintenance of pumps can prevent costly downtime. Inspect seals and bearings frequently. Monitor for unusual noises or vibrations. Simple checks can extend a pump's life. Choosing the right pump for each task is vital. Consider the fluid type, temperature, and flow rate. Making informed choices leads to better efficiency.

Sometimes operators overlook these details. This oversight can lead to inefficiencies. Proper training and awareness can help avoid common pitfalls in pump selection. Each application has unique needs, and understanding them is key to success.

Why Fluid Pumps Are Essential for Efficient Industrial Operations? - Types of Fluid Pumps Used in Industrial Settings

| Pump Type | Application | Advantages | Disadvantages |

|---|---|---|---|

| Centrifugal Pump | Water supply, chemical processing | High flow rates, simple design | Limited suction capability |

| Positive Displacement Pump | Viscous fluids, heavy oils | Excellent pressure capability | More complex maintenance |

| Peristaltic Pump | Food & beverage, pharmaceuticals | Non-contaminating, self-priming | Limited pressure range |

| Diaphragm Pump | Corrosive liquids, slurries | Handles solids, seals well | Lower flow rates compared to centrifugal |

| Gear Pump | Oil transfer, hydraulic fluids | Consistent flow, compact design | Sensitive to contamination |

Benefits of Fluid Pumps for Operational Efficiency

Fluid pumps play a crucial role in enhancing operational efficiency in various industries. By transporting liquids, they ensure smooth production processes. A well-functioning pump reduces downtime. This translates to increased productivity and lower operational costs.

When systems break down, the impact can be significant. Delays in processes increase expenses. Maintenance can also be costly and time-consuming. Therefore, investing in reliable fluid pumps is vital. They can handle various pressures and flow rates. This adaptability leads to optimized workflows in a manufacturing setting.

In addition, fluid pumps can improve resource management. Proper flow control prevents wastage. Efficient use of materials contributes to sustainability. However, not all pumps are equally efficient. Some designs may require frequent upkeep. Making informed choices about pump selection is essential. Regular assessments can lead to better performance.

Key Applications of Fluid Pumps in Various Industries

Fluid pumps play a vital role in a range of industries, ensuring the smooth operation of processes. In the chemical sector, for instance, they are crucial for safely transferring corrosive substances. According to a report from the Fluid Power Journal, over 30% of operational costs in this sector can be attributed to inefficient fluid management. Effective pumps can reduce this waste significantly.

In the food and beverage industry, fluid pumps handle everything from water to syrup. They must comply with strict hygiene standards. A study from the Food Processing Institute indicates that improper pumping systems can lead to contamination, causing costly recall. This underlines the importance of reliable pump technology in maintaining product quality.

Moreover, the oil and gas industry relies heavily on robust fluid pumping systems. They are necessary for extracting crude oil and transporting it. Research indicates that up to 25% of energy losses can occur during fluid transport due to outdated pump technologies. Enhancing the efficiency of pumps can optimize resource use and reduce environmental impact.

Maintenance Practices for Ensuring Pump Efficiency

Maintaining efficient fluid pumps is crucial for industrial operations. Regular maintenance practices can prevent failures and improve productivity. Simple yet effective measures include routine inspections. Checking for leaks, unusual noises, and fluctuations in pressure can help identify problems early.

Additionally, cleaning the pump components should not be overlooked. Dust and debris can accumulate and impede performance. Operators often forget this step, leading to unnecessary wear. Keeping the pump clean enhances its reliability and longevity.

However, relying solely on scheduled maintenance can be a mistake. A reactive approach may lead to unexpected downtimes. Reflecting on past issues can help teams refine their strategies. Training staff to recognize symptoms of pump failures fosters a proactive culture.

Importance of Pump Maintenance for Industrial Efficiency

Related Posts

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance

-

Top Benefits of Using Chemical Injection Pumps in Industrial Applications

-

10 Best Well and Pump Systems for Homeowners in 2026?

-

Top 10 Direct Pumps: Key Features and Buying Guide for 2023

-

How to Maintain Your Well and Pump for Optimal Performance?