10 Essential Tips for Choosing the Right Sanitary Pumps for Your Needs

In the rapidly evolving landscape of the food and beverage, pharmaceutical, and chemical industries, the selection of the right sanitary pumps is crucial for maintaining product integrity and ensuring compliance with stringent hygiene standards. According to a recent report by the MarketsandMarkets, the global sanitary pump market is projected to grow from USD 3.16 billion in 2020 to USD 4.22 billion by 2025, driven by increasing demand for high-quality products and the need for effective waste management systems. This underscores the vital role that sanitary pumps play in facilitating efficient operations while adhering to sanitation regulations.

Choosing the right sanitary pumps can significantly impact operational efficiency and product safety. Factors such as pump material, design, and compatibility with various fluids must be carefully considered to avoid common pitfalls that can lead to costly downtime or contamination. Industry standards, such as those set by the 3-A Sanitary Standards and the FDA, further emphasize the importance of selecting pumps that not only meet performance expectations but also uphold the highest levels of sanitation. By understanding these essentials, businesses can make informed decisions that enhance productivity and safeguard their reputation in an increasingly competitive market.

Factors to Consider When Selecting Sanitary Pumps for Food Industry Applications

When selecting sanitary pumps for food industry applications, several critical factors must be considered to ensure efficiency and compliance with health standards. One of the most important considerations is the material of construction. Pumps used in food production must be made from materials that can withstand harsh cleaning chemicals while preventing contamination. Stainless steel is often preferred due to its non-reactive nature and ease of cleaning.

Additionally, flow rates and pump efficiency play a significant role in the selection process. According to a report by the Food and Drug Administration (FDA), maintaining specific flow rates is vital for achieving optimal product consistency and quality in food processing. This means selecting a pump that can handle the viscosity and particulate content of the fluids being transferred. It's also essential to evaluate the sanitary design of the pump, including smooth surfaces and minimal crevices, to facilitate thorough cleaning and prevent microbial growth.

Tip: Always consider the total cost of ownership, which includes purchase price, maintenance, and operational costs. This holistic view will help you make informed decisions that balance initial investments with long-term operational efficiency. Another tip is to engage with suppliers who provide clear specifications and testing data, ensuring that the pumps meet stringent sanitary standards required in food production. The use of third-party certifications can also help in verifying the quality and compliance of chosen pumps, safeguarding both consumer health and business reputation.

Understanding the Different Types of Sanitary Pumps and Their Uses

When selecting sanitary pumps, it's crucial to understand the various types available, each designed for specific applications within the food, beverage, and pharmaceutical industries. Centrifugal pumps are popular for their efficiency and ability to handle large volumes of fluid. They work by using a rotating impeller to add velocity to the fluid, making them ideal for low-viscosity applications. However, they may not be suitable for more viscous substances or where gentle handling is required.

On the other hand, positive displacement pumps, such as diaphragm and rotary lobe pumps, excel in handling thick, viscous fluids and ensuring consistent flow rates regardless of the viscosity. Diaphragm pumps, for example, create a seal using a flexible membrane, which is particularly beneficial in applications requiring contamination-free transfer of sensitive materials. Rotary lobe pumps utilize two or more lobes that rotate to move the fluid, making them ideal for handling shear-sensitive products. Understanding these differences will help you choose a pump that not only meets your operational requirements but also ensures product integrity and compliance with sanitary standards.

Key Performance Indicators for Evaluating Sanitary Pump Efficiency

When selecting the right sanitary pumps for your operational needs, understanding key performance indicators (KPIs) is crucial for evaluating pump efficiency. Key metrics such as flow rate, pressure, and energy consumption can directly impact both productivity and cost-effectiveness. According to recent industry reports, optimizing the flow rate can lead to a 15% increase in operational efficiency for food processing systems. Therefore, it’s vital to assess these parameters to ensure your pump meets the specific flow demands of your application.

One essential tip is to consider the materials of construction used in the pumps. Sanitary pumps need to be made from non-reactive, high-grade materials to maintain product purity and comply with hygiene standards. Additionally, a pump's efficiency can be significantly affected by its design, such as the impeller type and casing configuration. For instance, centrifugal pumps typically provide higher efficiency for low-viscosity fluids, making them a great choice in industries specializing in dairy or beverage processing.

Another critical factor is the Energy Efficiency Ratio (EER), which measures the efficiency of the pump’s performance relative to its energy input. A good EER can save companies substantial energy costs, with studies indicating that energy-efficient pumps can reduce overall energy use by up to 30%. Regular maintenance and monitoring of your pump systems can also ensure they operate at peak efficiency, further enhancing your facility’s productivity while minimizing downtime.

Material Compatibility: Ensuring Pump Durability in Sanitary Applications

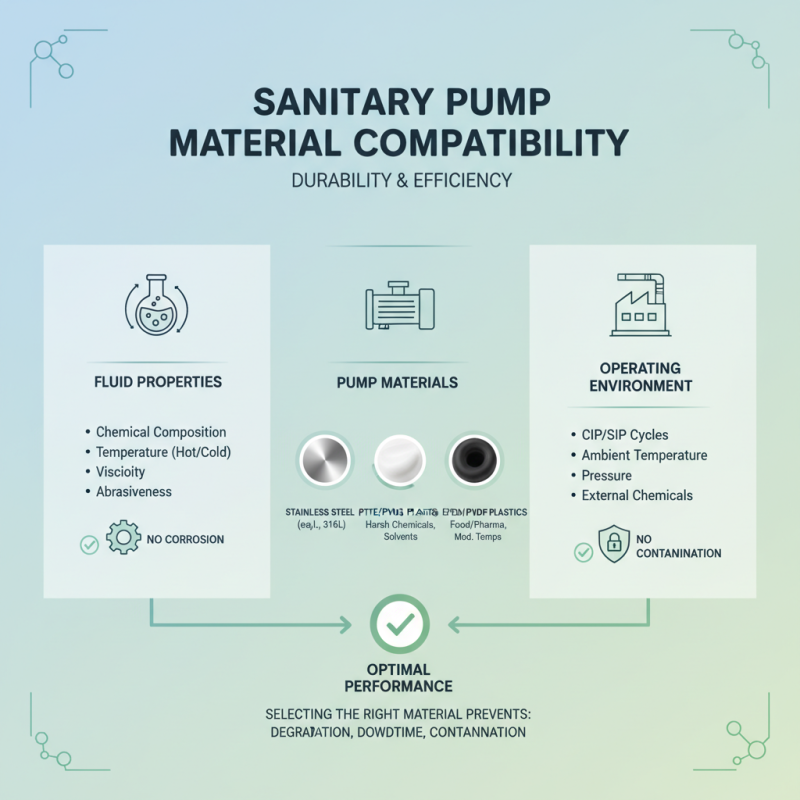

When selecting sanitary pumps for your applications, ensuring material compatibility is paramount to achieving durability and efficiency. Different materials interact uniquely with various substances, and choosing the wrong pump material can lead to degradation, contamination, or costly downtime. For example, some materials may corrode when exposed to harsh chemicals, while others may not withstand high temperatures. It’s essential to evaluate both the properties of the fluid being pumped and the operating environment to select the most suitable material.

Tip: Always conduct a compatibility assessment between the pump materials and the liquids being handled. Consider factors like pH level, temperature, and potential for abrasion. This assessment not only prolongs the life of your pump but also protects product integrity.

Additionally, it’s important to consult manufacturer guidelines regarding fluid compatibility for the pump materials and seek advice from industry experts if necessary. This step can provide valuable insights on which materials are best suited for specific applications, ensuring that the pump can handle the required sanitary standards.

Tip: Opt for pumps made from robust materials, such as stainless steel or specialized polymers, which are known for their resistance to a wide range of chemicals and mechanical stresses. By prioritizing material compatibility in your pump selection, you will enhance operational efficiency and minimize the risk of costly failures.

Regulatory Compliance and Standards for Sanitary Pump Selection

When selecting sanitary pumps, understanding regulatory compliance and industry standards is crucial. These standards ensure that the pumps are safe for use in sensitive environments, especially in food, pharmaceutical, and biotechnology industries. Familiarize yourself with relevant regulations such as FDA guidelines or European Hygiene Standards, as they often dictate the design, materials, and performance requirements for sanitary equipment.

One essential tip for choosing the right sanitary pump is to investigate the materials of construction. The materials should be non-reactive and easy to clean, minimizing any risk of contamination. Stainless steel, particularly grades like 304 or 316L, is commonly used because of its resistance to corrosion and suitability in hygienic applications. Additionally, consider the surface finish and whether it meets the required Ra values for sanitary applications to ensure that it minimizes bacterial growth.

Another important factor to consider is the pump’s certification and testing standards. Look for pumps that have been certified by recognized organizations that validate their compliance with sanitary standards. This not only ensures that the pump is effective for your needs but also reinforces your commitment to maintaining high hygiene and safety standards in your operations.

10 Essential Tips for Choosing the Right Sanitary Pumps for Your Needs

| Tip No. | Tip | Considerations | Standards & Compliance |

|---|---|---|---|

| 1 | Assess Your Application | Understand the fluid type, viscosity, and temperature range. | FDA, USDA Compliance |

| 2 | Know the Flow Rate Requirements | Determine the required flow rate and pressure. | EHEDG Guidelines |

| 3 | Evaluate Material Compatibility | Ensure materials can withstand your fluid's chemical properties. | ISO 2859 |

| 4 | Consider Maintenance Needs | Choose pumps with easy maintenance features. | 3-A Sanitary Standards |

| 5 | Review Safety Features | Make sure pumps have built-in safety mechanisms. | OSHA Regulations |

| 6 | Select the Right Pump Type | Assess whether a centrifugal, positive displacement, or specialty pump is best. | ANSI/ASME B73.1 |

| 7 | Evaluate Energy Efficiency | Check for energy-saving features and performance ratings. | Energy Star Program |

| 8 | Consider Size and Space | Measure available installation space to fit the pump. | Local Building Codes |

| 9 | Check Customer Support and Service | Ensure quality support and service options are available. | N/A |

| 10 | Understand Warranty and Reliability | Look for warranty options and pump durability. | N/A |

Related Posts

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

-

Why You Need a Fluid Transfer Pump for Efficient Liquid Handling

-

Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

The Future of Battery Pumps Revolutionizing Efficiency in Power Tools

-

How to Choose the Best Well Pump for Your Home Water Needs