10 Essential Tips for Choosing the Right Motor Pump for Your Needs?

Choosing the right motor pump can be challenging. With so many options available, how do you make the best decision? Understanding your specific needs is crucial. A motor pump’s specifications can vary greatly, impacting efficiency and performance.

Consider factors like flow rate and pressure requirements. These elements will guide you in selecting a suitable model. Remember, not all pumps are designed the same way. Some may excel in certain environments but falter in others.

Investing time in research is essential. Real-world applications can differ from theoretical capacities. Never hesitate to consult experienced professionals. Their insights can prove invaluable. Striking the balance between functionality and cost is often tricky yet necessary.

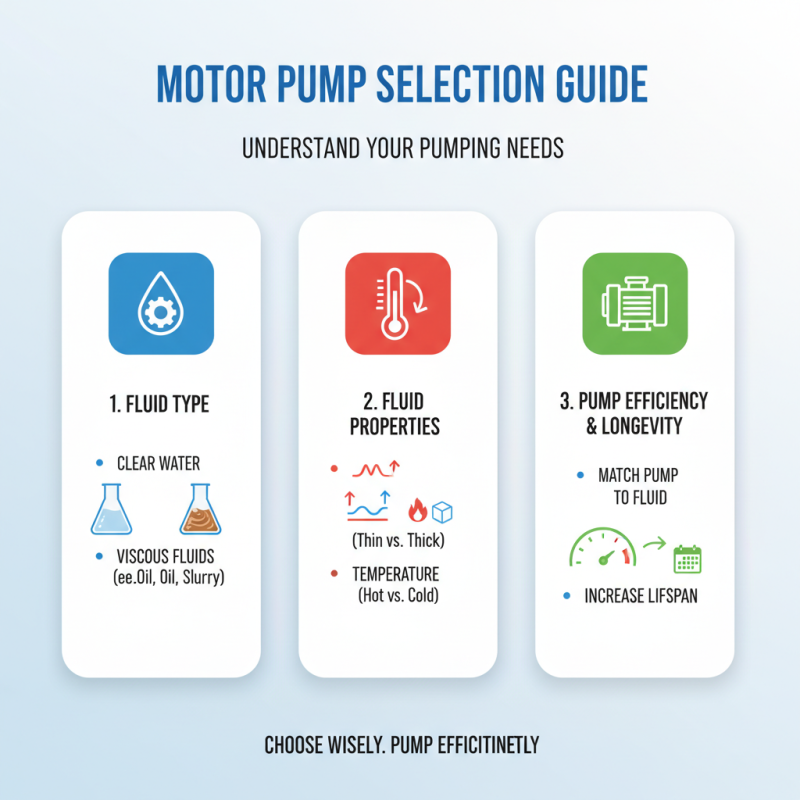

Understanding Your Pumping Needs and Application Requirements

Choosing the right motor pump starts with understanding your pumping needs. Consider the type of fluid you will handle. Is it clear water or something more viscous? Different fluids require different motor pumps. Assess the viscosity and temperature of the fluid. These factors affect the pump’s efficiency and longevity.

Next, think about your application requirements. What is the required flow rate? How much pressure do you need? These specifications are critical. If you're unsure, it might be helpful to consult with experts or do some research. Sometimes, the right choice isn't obvious. You might find that a pump seems ideal, but its specifications may not match your needs perfectly. Avoid rushing into a purchase; take the time to understand your specific situation. Every detail matters, from the motor's horsepower to the pump's design type. Make a checklist to compare features that really matter for your project.

Exploring Different Types of Motor Pumps and Their Uses

When selecting a motor pump, understanding the different types available is crucial. Centrifugal pumps are the most common. They move fluid through rotation. This makes them ideal for water, chemicals, and light slurries. A report from the Hydraulic Institute suggests that centrifugal pumps account for about 80% of the global pump market. Their efficiency and versatility make them a popular choice among industries.

Submersible pumps are another type worth considering. These pumps operate underwater and are commonly used for drainage or sewage. They are efficient in moving large volumes of water quickly. However, they can face challenges in handling solids. This can lead to clogs and reduce efficiency over time. Many users report that regular maintenance is essential to avoid downtime.

Diaphragm pumps are also important for specific applications. They are great for handling viscous fluids and slurries. However, they tend to be more complex and can have a higher initial cost. A recent study highlighted that diaphragm pumps are growing in demand, especially in the food and pharmaceutical industries. Choosing the right pump requires weighing these factors carefully.

Evaluating Key Specifications: Flow Rate, Pressure, and Power

When selecting a motor pump, understanding key specifications is crucial. Flow rate is the first thing to consider. It refers to the volume of liquid the pump can move in a specific time period. Measuring flow rate in gallons per minute (GPM) helps determine if the pump meets your needs. A low flow rate might result in sluggish performance, while a rate that's too high could lead to waste.

Pressure is another vital factor. It is defined as the force exerted by the fluid. This is measured in pounds per square inch (PSI). Understanding your application's pressure requirements is essential. If the pressure is too low, the system may fail to operate as intended. On the other hand, excessive pressure could damage components.

Power requirements should not be overlooked. Motor pumps require specific power to operate efficiently. Check the wattage to ensure it aligns with your power availability. If the pump draws too much power, it can strain your electrical system. Regularly reviewing these specifications is necessary for optimal performance. Each detail matters, and a small oversight can lead to bigger issues later.

10 Essential Tips for Choosing the Right Motor Pump for Your Needs

| Specification | Description | Example Values |

|---|---|---|

| Flow Rate | The volume of fluid that can be pumped per unit of time. | 10-1000 GPM (Gallons Per Minute) |

| Pressure | The force with which the pump can deliver the fluid, measured in PSI (Pounds per Square Inch). | 30-150 PSI |

| Power | The amount of energy consumed by the pump, usually measured in horsepower (HP). | 1-5 HP |

| Efficiency | The ratio of useful work output to total energy input, expressed as a percentage. | 60%-90% |

| Material | The construction material for the pump body, which affects durability and corrosion resistance. | Cast Iron, Stainless Steel, Plastic |

| Type | The kind of pump, which determines its operation and suitability for specific tasks. | Centrifugal, Positive Displacement |

| Inlet/Outlet Size | The diameter of the pump's inlet and outlet ports that affects flow capacity. | 1"-3" diameters |

| Power Source | The energy source that powers the pump, which influences its versatility and mobility. | Electric, Gasoline, Diesel |

| Noise Level | The amount of sound produced by the pump during operation, significant for noise-sensitive environments. | 60-80 dB |

| Portability | The ease with which the pump can be transported, relevant for field applications. | Stationary, Portable |

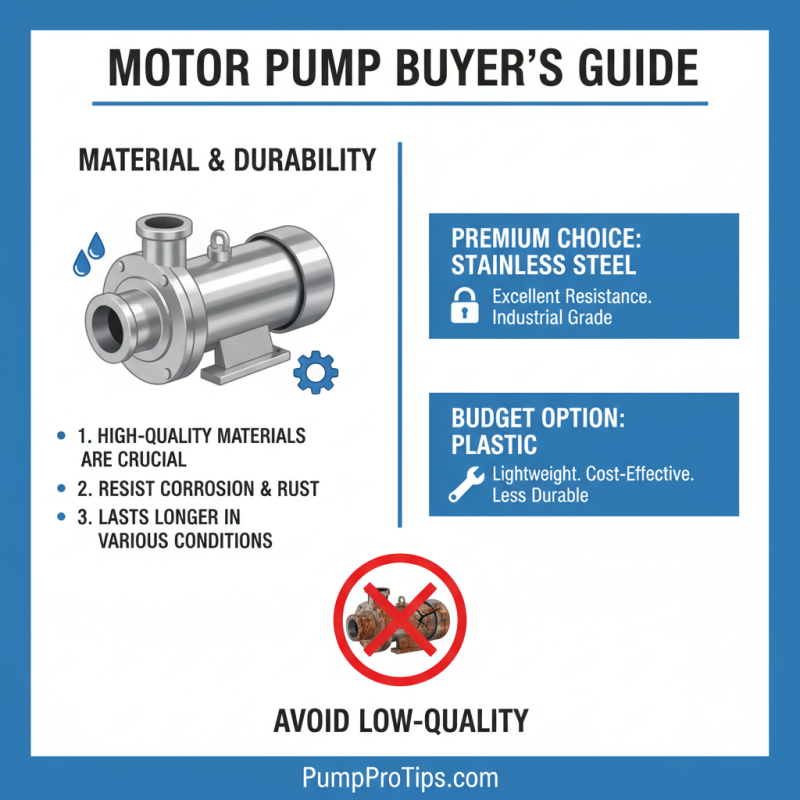

Considering Material and Durability for Long-Term Performance

When choosing a motor pump, the material and durability should be top considerations. A pump made from high-quality materials can withstand various conditions. Corrosion and rust might damage lower-quality options over time. Metals like stainless steel offer excellent resistance. Plastic alternatives can be light and cost-effective but may not last.

Look closely at your environment. Are you using the pump in a harsh setting? If so, consider options designed for extreme temperatures and pressures. If your pump will handle corrosive fluids, specific materials are necessary to prevent damage. Pumps that lack adequate protection can lead to frequent repairs.

Reflecting on your needs is crucial. Sometimes, budget constraints can limit options. However, investing in durable materials typically pays off. A pump that fails often incurs higher costs. Choose wisely, considering both long-term performance and your specific requirements. The right choice today can save time and money tomorrow.

Assessing Budget and Maintenance Factors in Pump Selection

Choosing the right motor pump requires more than just specifications. Budget constraints often dictate what options are available. It’s important to define your budget early in the process. Determine how much you are willing to spend. Consider both the initial cost and long-term expenses.

Maintenance is another critical factor. Some pumps require more upkeep than others. An inexpensive pump may cost more in repairs over time. Think about how often you can maintain the pump. Ask yourself if you have the time and resources for regular check-ups. Remember, some pumps are designed for easy maintenance, while others demand significant effort.

Look for detailed information about ongoing costs too. Calculate potential expenses associated with repairs and servicing. A pump that seems like a great deal initially may not be cost-effective in the long run. Ultimately, balancing budget with maintenance needs is crucial before making a decision. Reflect on your actual needs and circumstances, and weigh your options carefully.

Budget and Maintenance Factors in Motor Pump Selection

Related Posts

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

2026 Top Pump Solutions for Every Industry Need?

-

Why Are Micro Pumps Essential for Modern Technology Applications?

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

2026 Top Trends in Chemical Diaphragm Pumps to Watch Out For?

-

Why Precision Pumps Are Essential for Precision Engineering Applications