Why You Need Effective Pump Solutions for Your Business Efficiency

In today's competitive business landscape, the efficiency of operations often hinges on the reliability and effectiveness of critical equipment. Among these, pump solutions stand out as fundamental components that facilitate the seamless movement of fluids in various industrial applications. As noted by industry expert Dr. John Smith, a leading authority on fluid dynamics, "Effective pump solutions are not just a component of workflow; they are the lifeblood of operational efficiency." This sentiment underscores the pressing need for businesses to invest in high-quality pump solutions that not only enhance their processes but also drive overall productivity.

The significance of pump solutions extends beyond mere functionality; they play a crucial role in energy consumption, maintenance costs, and the longevity of machinery. With the right pump systems in place, companies can optimize their resource management while minimizing downtime and operational hiccups. In an era where every second and every drop counts, neglecting the importance of effective pump solutions could lead to inefficiencies that hinder growth and innovation.

Moreover, adopting sophisticated pump solutions can enable businesses to adapt to dynamic market demands and regulatory requirements, allowing them to stay ahead of competitors. As industries continue to evolve, so too must the strategies employed to ensure efficiency and reliability in operations. Embracing advanced pump solutions not only safeguards a company's workflow but also secures its position in the market as a leader in operational excellence.

The Importance of Pump Solutions in Industry Efficiency

Effective pump solutions play a crucial role in enhancing industry efficiency across various sectors. In industrial processes, pumps are responsible for the movement of fluids, which can include water, chemicals, and other materials essential for operations. The efficiency of these pumps directly impacts the overall productivity of a business. When pumps operate at their optimal performance levels, they reduce energy consumption and minimize downtime, allowing companies to allocate resources more effectively and improve their bottom line.

Furthermore, the strategic implementation of pump solutions can lead to significant cost savings. For instance, systems designed with advanced technology can predict maintenance needs, thereby preventing unexpected failures and costly repairs. Additionally, utilizing environmentally friendly pump solutions can contribute to sustainability efforts, aligning with global standards and industry demands for greener practices. By investing in high-quality pump solutions, businesses can not only enhance their operational efficiency but also bolster their reputation in a competitive marketplace, demonstrating a commitment to reliability and environmental responsibility.

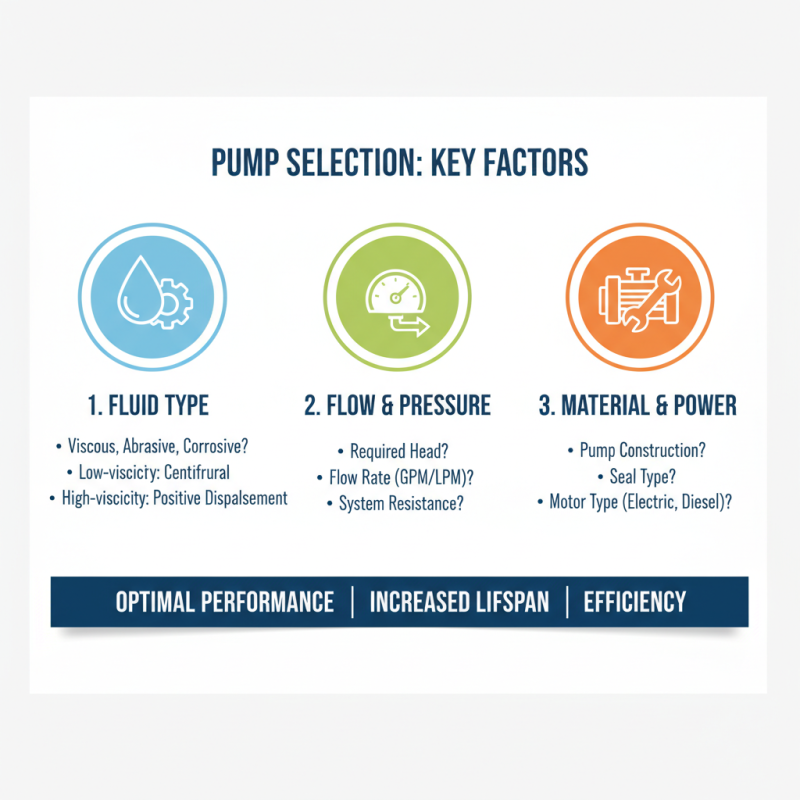

Key Factors Driving Pump Selection for Optimal Performance

When selecting pump solutions for your business, several key factors must be considered to ensure optimal performance. One of the primary considerations is the type of fluid being handled. Whether it’s viscous, abrasive, or corrosive, understanding the properties of the fluid is crucial in determining the appropriate pump type. For instance, centrifugal pumps are typically ideal for low-viscosity liquids, while positive displacement pumps cater to thicker fluids. Matching the pump to the fluid characteristics not only enhances efficiency but also prolongs the lifespan of the equipment.

Another essential factor is the required flow rate and pressure. Calculating the system's specific needs ensures that the pump can handle the demand without overworking or under-delivering. Too often, businesses underestimate the importance of proper sizing, which can lead to inefficient operations and increased energy costs. Additionally, consider the installation environment; factors such as temperature fluctuations, humidity, and space constraints can all influence pump performance. By evaluating these elements, businesses can make informed decisions that align pump selection with their operational needs, ultimately boosting overall efficiency and productivity.

Impact of Pump Efficiency on Operational Costs and Profit Margins

The impact of pump efficiency on operational costs can be profound, particularly for industries that rely heavily on fluid transportation. When pumps operate at optimal efficiency, they consume less energy, reducing the overall power costs associated with their operation. This energy savings not only lowers monthly utility bills but also mitigates the need for additional budget allocations for energy expenditures. Efficient pumps can transform energy into mechanical work more effectively, translating into less wasted resources and ultimately leading to substantial cost savings for the business.

Furthermore, the implications of pump efficiency extend to profit margins as well. By minimizing operational costs through efficient pumping solutions, businesses can enhance their financial performance. Higher efficiency means reduced wear and tear on equipment, leading to lower maintenance costs and extending the lifespan of the pumps. This not only maximizes the return on investment for the machinery but also allows companies to allocate their resources toward other growth initiatives. Ultimately, investing in effective pump solutions contributes directly to a healthier bottom line and sustains competitive advantage in the market.

Case Studies: Successful Pump Implementations in Various Sectors

In various sectors, the implementation of effective pump solutions has proven to be a game-changer for business efficiency. For instance, in the water treatment industry, a recent report by the International Water Association indicated that optimized pumping systems can reduce energy consumption by up to 30%. This significant reduction not only lowers operational costs but also allows facilities to redirect financial resources toward other crucial operational areas. One notable case study involved a municipal water treatment plant that upgraded its pumping systems, which resulted in an impressive increase in flow efficiency, leading to improved overall service delivery.

Another compelling example can be found in the oil and gas sector, where a study by the American Petroleum Institute highlighted that advanced pump technologies lead to enhanced reliability and reduced downtime, with maintenance costs potentially dropping by 25%. This improvement not only boosts output but also improves safety conditions in demanding operational environments. A specific case reported the successful integration of smart pump monitoring systems, which helped an oil refinery proactively address maintenance issues, minimizing unexpected failures and optimizing production schedules. The positive impact of adopting such pump solutions spans across multiple industries, underscoring their vital role in enhancing operational efficiency and profitability.

Future Trends in Pump Technology: Innovations Enhancing Business Efficiency

In an era where operational efficiency is paramount, the evolution of pump technology plays a critical role in driving business success. Recent reports highlight that advanced pump solutions can improve system efficiency by up to 20%, significantly reducing energy costs and enhancing productivity. Innovations such as intelligent monitoring systems, which utilize IoT technology, allow businesses to track performance metrics in real time, leading to proactive maintenance and decreased downtime. These innovations not only streamline operations but also extend the lifespan of pumping equipment, further optimizing resource management.

Moreover, emerging trends such as the integration of smart pumps equipped with data analytics capabilities are set to transform industrial processes. According to a report by MarketsandMarkets, the smart pumps market is projected to reach $5.2 billion by 2025, growing at a CAGR of 12% from 2020. Such growth indicates a clear shift toward automation and data-driven decision-making in pump systems. Businesses embracing these technologies can expect improved operational insights and enhanced decision-making processes, ensuring they remain competitive in an increasingly demanding market landscape. With these advancements, effective pump solutions are not just advantageous; they are essential for sustaining business efficiency and growth.

Future Trends in Pump Technology: Enhancing Business Efficiency

Related Posts

-

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

-

How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

Top 10 High Viscosity Pumps for Efficient Fluid Handling in Industry

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

-

How to Choose the Best Well Pump for Your Home Water Needs