How to Choose the Right Fluid Transfer Pump for Your Needs?

Selecting the right fluid transfer pump is crucial. A suitable pump can improve efficiency and reduce operational issues. It is essential to understand your specific needs before making a decision.

Consider factors like fluid type, viscosity, and flow rate. Each application requires unique pump specifications. For example, a pump for thick oils will differ from one used for water. Efficiency matters, but so does reliability.

Many users overlook maintenance requirements. A complex pump can lead to unexpected downtime. Therefore, always think about longevity and ease of service. In some cases, users might find themselves wishing they chose differently. Make informed choices, and take your time evaluating options.

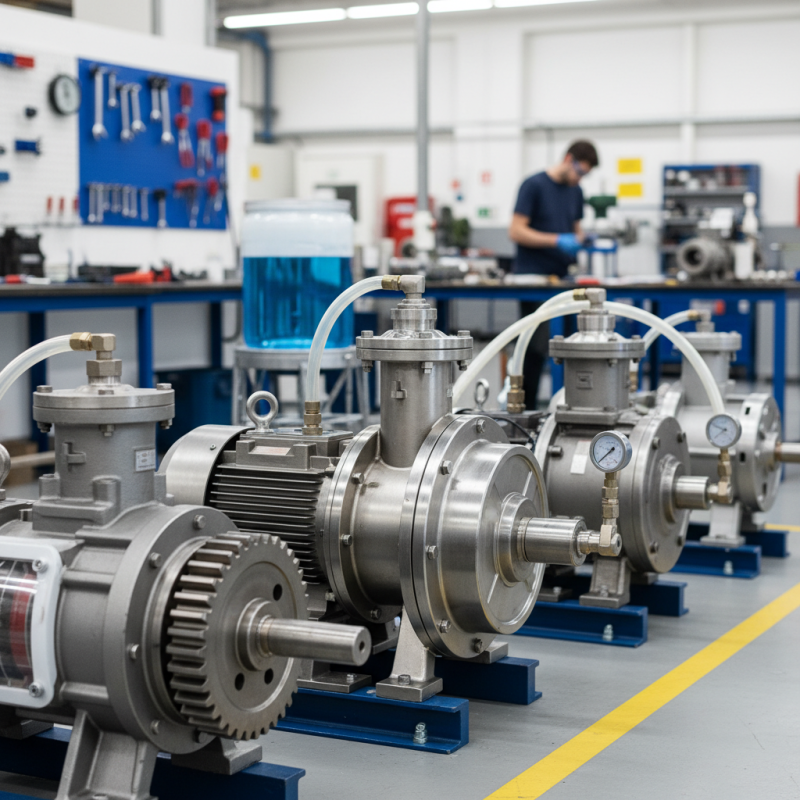

Understanding the Different Types of Fluid Transfer Pumps

When selecting a fluid transfer pump, understanding the different types is crucial. Positive displacement pumps, for instance, are widely used. They operate by trapping a fixed amount of fluid and forcing it through the discharge pipe. According to a recent industry report, these pumps make up about 30% of the market share in industrial applications.

Another category is centrifugal pumps. These are often preferred for large volumes of fluid transfer. They utilize rotational energy to move fluids efficiently. Data suggests that centrifugal pumps account for approximately 50% of the global fluid pump market. Their ability to handle low-viscosity liquids makes them versatile but may lead to cavitation issues if not sized correctly.

Moreover, specialty pumps exist for unique applications. These can be tailored for specific fluids, like chemicals or slurries. However, selecting the wrong type can lead to inefficiencies or even equipment failure. Many operators underestimate the importance of matching pump type with fluid characteristics. This can result in unanticipated maintenance costs or downtime. It’s vital to evaluate the specific needs to avoid costly mistakes.

Assessing Your Specific Fluid Transfer Requirements

When selecting a fluid transfer pump, understanding your specific requirements is crucial. An industry report from the Fluid Transfer Association highlights that 65% of pump failures are due to improper selection. Evaluating your fluid's viscosity, temperature, and chemical compatibility reduces risks. For example, a pump meant for oil may not suit water-based fluids. Each fluid behaves differently under pressure, and knowing these characteristics can save time and resources.

Next, consider the flow rate needed for your application. According to a study by the Pump Efficiency Council, underestimating flow requirements can lead to inefficiencies. Many users have reported decreasing productivity when their pump fails to meet expectations. A detailed assessment of the required flow rate helps avoid such problems. Refining this number often requires trial and error. Many engineers recommend incremental testing to identify the optimal flow rate.

Lastly, think about the pump's environment. Will it operate in hazardous conditions? A report from the Safety Pump Institute suggests that 30% of workplace accidents are linked to using the wrong equipment in challenging environments. Consider factors such as space limitations and ambient temperature. Ensure the chosen pump can withstand these conditions. Failing to account for environmental aspects can lead to equipment failure and safety hazards.

Fluid Transfer Pump Selection Criteria

This chart illustrates the importance level of different criteria to consider when selecting a fluid transfer pump for specific needs. Each criterion is rated on a scale of 1 to 10, reflecting how critical it is in the selection process.

Key Features to Consider When Selecting a Pump

When selecting a fluid transfer pump, consider several key features. The pump’s flow rate is critical. It determines how quickly fluids move. A higher flow rate saves time, but may cause overheating. Evaluate the viscosity of the liquid as well. Thick fluids require more powerful pumps, which can be costly.

Material compatibility is another factor. Ensure the pump can handle the fluid without damage. For corrosive liquids, choose materials resistant to chemical reactions. It’s easy to overlook this aspect, leading to equipment failure.

Also, think about the pump's portability. A lightweight pump can simplify transport, especially for fieldwork. Yet, it might sacrifice power. Balance efficiency with practicality. Lastly, check energy consumption. An efficient pump lowers operational costs but may have a higher upfront price.

How to Choose the Right Fluid Transfer Pump for Your Needs? - Key Features to Consider When Selecting a Pump

| Feature | Description | Importance |

|---|---|---|

| Flow Rate | The amount of fluid transferred per unit of time, typically measured in gallons per minute (GPM) or liters per minute (LPM). | Determines how quickly you can complete the transfer. |

| Pressure Rating | The maximum pressure the pump can handle, measured in PSI (pounds per square inch). | Critical for ensuring the pump can handle your specific application without damage. |

| Material Compatibility | The types of fluids that the pump can transfer safely without corrosion or degradation. | Ensures long-term reliability and prevents contamination. |

| Power Source | The type of energy used to operate the pump, such as electric, gas, or manual. | Affects portability and usability in various environments. |

| Port Size | The diameter of the inlet and outlet ports which dictates the hose or piping size needed. | Impacts flow efficiency and compatibility with existing systems. |

| Weight | The overall weight of the pump can indicate its portability and application suitability. | Important for mobile applications and ease of use. |

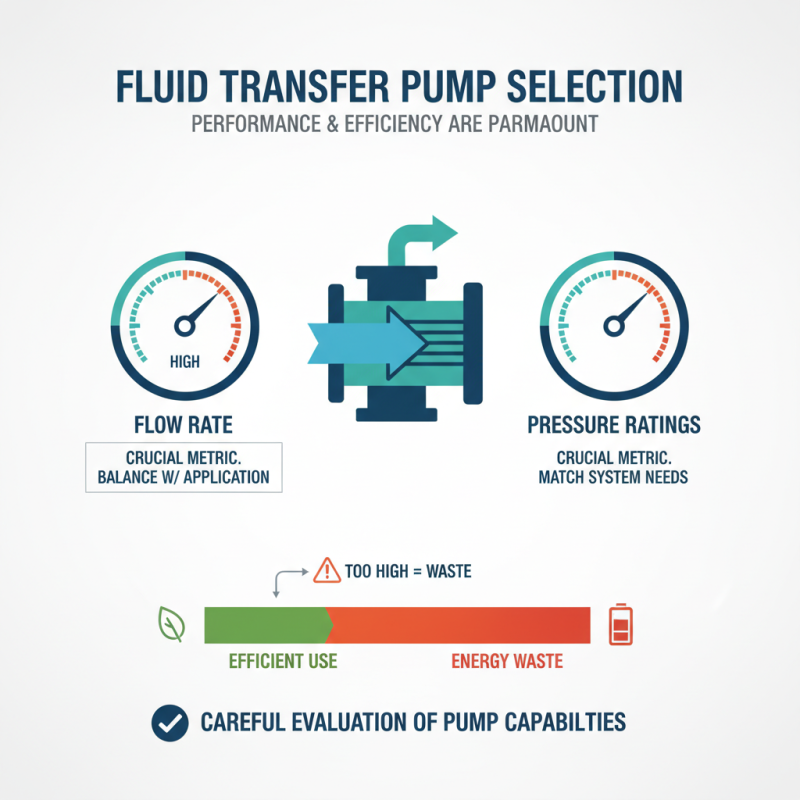

Evaluating The Performance and Efficiency of Fluid Pumps

When selecting a fluid transfer pump, performance and efficiency take center stage. The pump's flow rate and pressure ratings are crucial metrics. A higher flow rate may seem desirable, but it can lead to energy waste if not balanced with the application requirements. This creates a need for careful evaluation of demands against pump capabilities.

Efficiency is equally important. Different pumps have varying energy consumption levels, which affects operational costs. Some systems may choose a low-efficiency pump for initial savings, only to face increased power bills later. This choice often requires reevaluation of long-term expenses versus upfront costs.

Consider also the type of fluid being moved. Viscosity impacts performance significantly. A pump designed for thin liquids may struggle with thicker fluids. Mistakes in selecting the right fluid type can lead to operational inefficiencies or even damage the system. Reflection on the specific application is critical to avoid these pitfalls.

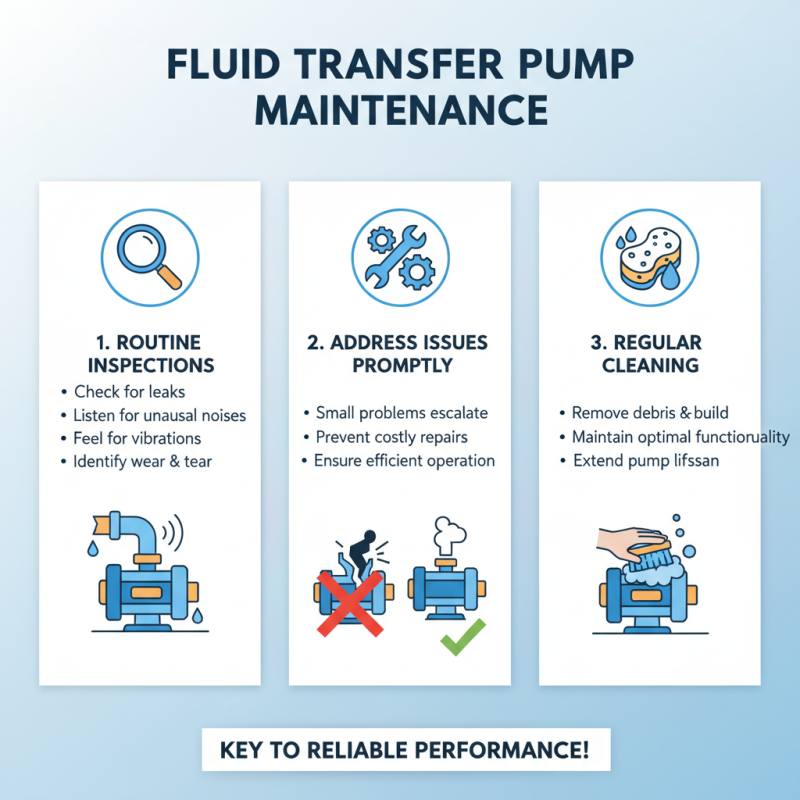

Maintenance Tips for Ensuring Optimal Pump Functionality

Regular maintenance is essential for ensuring your fluid transfer pump operates efficiently. Start with routine inspections to identify any wear and tear. Look for leaks, unusual noises, or vibrations. These signs often indicate underlying issues that need addressing. Small problems can escalate into larger, costly repairs if ignored. Cleaning the pump regularly also helps maintain optimal functionality.

Another important aspect is lubricating moving parts. Neglecting this step can lead to friction and wear. Ensure you use the right type of lubricant as specified in the manual. You might think skipping lubrication won’t hurt. But over time, this habit could cause significant damage.

Don’t forget to check the hoses and connections. Cracks or loose fittings can lead to leaks. Replace any compromised components immediately. Review your maintenance schedule frequently. Evaluate what’s working and what isn’t. Continuous improvement is crucial. Adapting your approach can greatly enhance the pump's lifespan and efficiency.

Related Posts

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

Top Benefits of Using Chemical Injection Pumps in Industrial Applications

-

Why You Need a Fluid Transfer Pump for Efficient Liquid Handling

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency

-

Top Tips for Choosing the Best Well and Pump Systems in 2025