Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

In the fast-paced world of industrial applications, selecting the right chemical pump is crucial for enhancing operational efficiency and ensuring safety. With numerous options available, making an informed choice can be daunting. This guide aims to simplify the selection process by providing essential tips and insights tailored to your specific needs. Understanding the various types of chemical pumps, their operational mechanisms, and suitability for different applications will empower you to make decisions that enhance productivity while minimizing risks.

From considering material compatibility to assessing flow rates and energy efficiency, we will explore the key factors that influence your selection. By following our expert recommendations, you can unlock the full potential of your chemical pump, streamline processes, and achieve long-term benefits for your industrial operations.

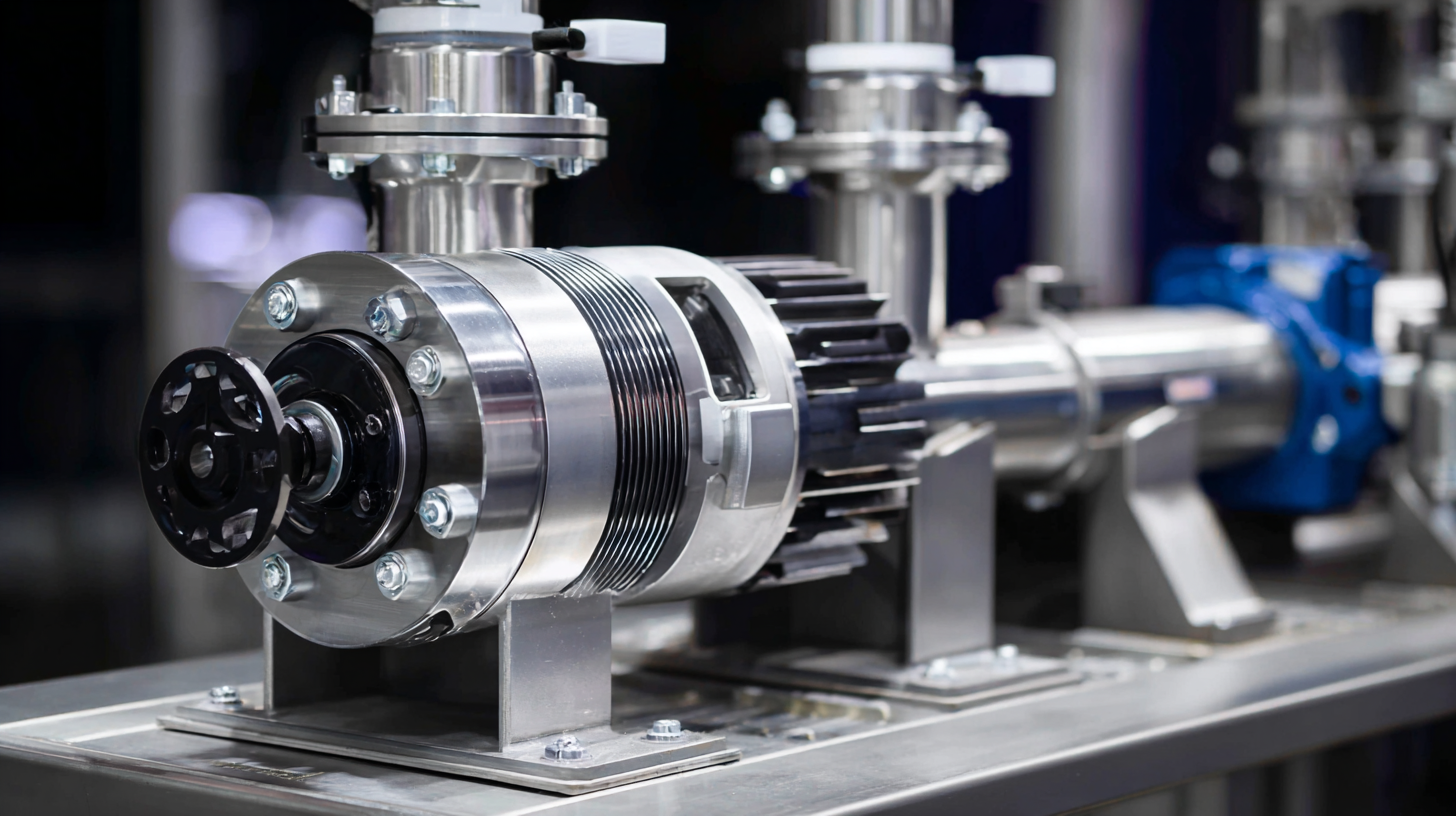

Understanding the Different Types of Chemical Pumps for Industrial Use

When it comes to selecting a chemical pump for industrial applications, understanding the different types available is essential. Among the most common types are centrifugal pumps, diaphragm pumps, and peristaltic pumps. Centrifugal pumps are ideal for large volumes of liquid with lower viscosity, commonly used for transporting water-like substances. Conversely, diaphragm pumps excel in handling corrosive or viscous fluids, making them suitable for applications involving chemicals and slurries. Peristaltic pumps, renowned for their ability to handle abrasive and shear-sensitive materials, offer precise flow control and are often utilized in food processing and pharmaceuticals.

**Tips:** When choosing a pump, consider the fluid’s chemical properties, including viscosity and corrosiveness. This will guide you toward the right materials and construction for durability. Additionally, evaluate the required flow rate and pressure conditions to ensure optimal pump performance for your specific industrial needs.

Furthermore, pay attention to maintenance requirements and the pump’s compatibility with your existing systems. Regular maintenance can prevent costly downtimes and extend the lifespan of your equipment. Understanding these factors will enable you to make informed decisions, ensuring you select a chemical pump that meets your operational efficiency and safety standards.

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

| Pump Type | Flow Rate (GPH) | Max Pressure (PSI) | Material Compatibility | Typical Applications |

|---|---|---|---|---|

| Diaphragm Pump | 5 - 300 | 100 | Acids, Bases, Solvents | Chemical Transfer, Wastewater Treatment |

| Centrifugal Pump | 10 - 1500 | 250 | Water, Mild Chemicals | Cooling Systems, Circulation |

| Peristaltic Pump | 1 - 300 | 60 | Food, Pharmaceuticals | Fluid Transfer, Dosing |

| Gear Pump | 0.5 - 800 | 150 | Viscous Fluids, Oils | Lubrication, Ink, Coatings |

| Screw Pump | 10 - 1000 | 200 | Heavy Oils, Slurries | Biomass, Waste Products |

Key Factors to Consider When Selecting a Chemical Pump

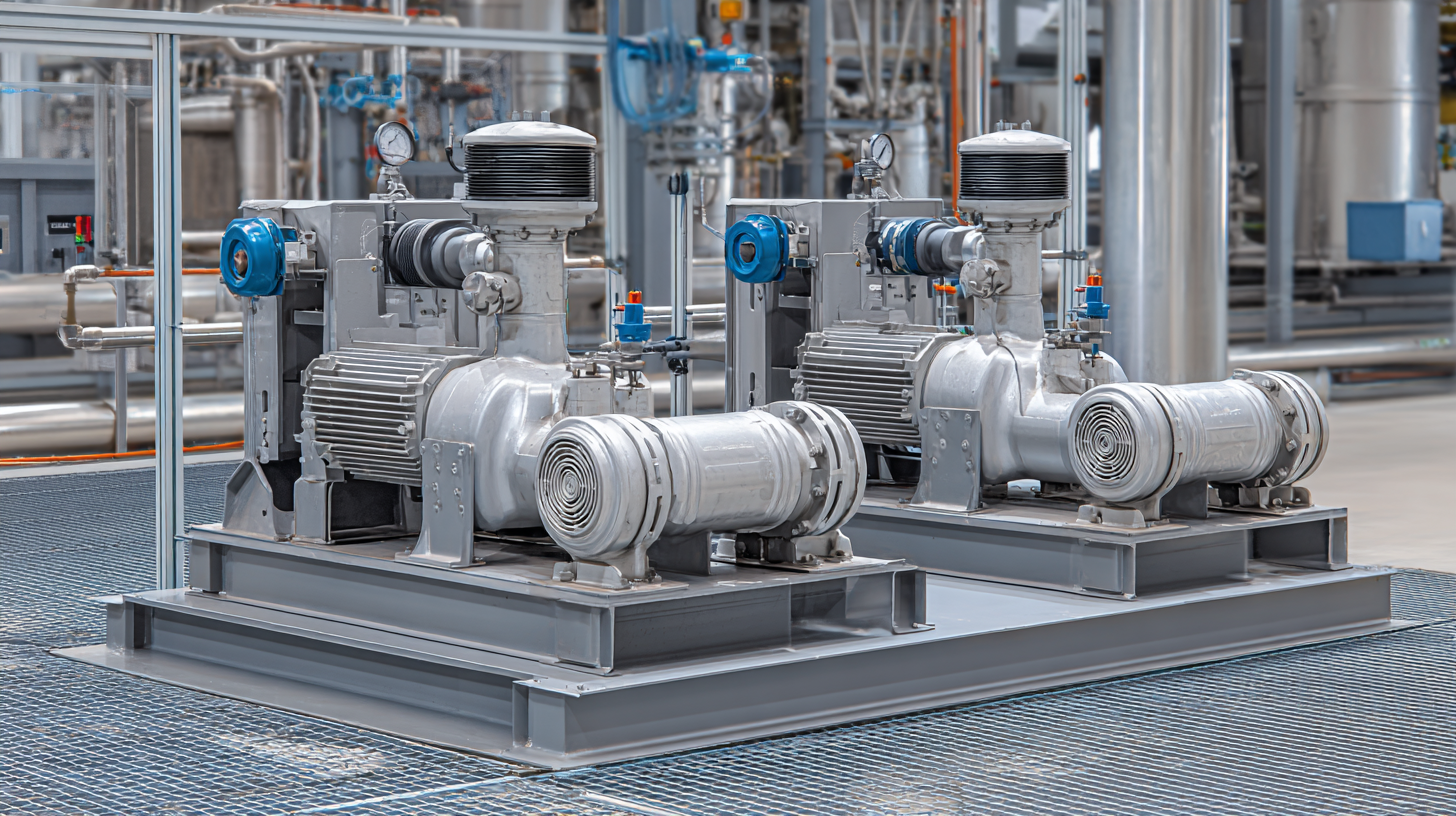

When selecting a chemical pump, particularly for applications involving ethylene oxide (EO), reliability and longevity are paramount. EO is one of the most significant chemicals used in industrial processes, necessitating pumps that can withstand its harsh characteristics. According to recent industry reports, choosing the right material compatibility and design features can enhance pump performance and lifespan. For instance, pumps constructed with corrosion-resistant materials can drastically reduce maintenance needs, leading to operational uptime and efficiency.

Moreover, as industries strive to adopt sustainable practices, the role of heat pumps is becoming increasingly prominent. Data from recent studies highlight that industrial heat pumps can significantly reduce carbon footprints while offering reliable service. When evaluating chemical pumps, consider factors such as energy efficiency, operating temperatures, and ease of integration with existing systems. Adopting advanced technologies like digital monitoring systems can further optimize performance, allowing for predictive maintenance and reduced downtime, ultimately aligning with the evolving standards of operational excellence in the industrial sector.

Evaluating Pump Performance: Flow Rate, Pressure, and Viscosity

When selecting a chemical pump for industrial applications, evaluating pump performance metrics such as flow rate, pressure, and viscosity is critical. Accurate flow rate estimation is particularly vital in ensuring that the pump meets operational requirements without compromising efficiency. Recent studies indicate that the volumetric efficiency of pumps can significantly fluctuate under high pressure, which often leads to issues such as leakage and reverse flow. For instance, one study presented a model demonstrating that motor-driven two-dimensional piston pumps experience considerable efficiency losses when subjected to variable conditions, emphasizing the importance of maintaining optimal flow rates.

In addition to flow rate, pressure plays a crucial role in pump performance, especially in applications requiring the transfer of viscous fluids. The design of the impeller and the geometry of the thrust tube can drastically influence both hydraulic and hemolytic performance in centrifugal pumps. Research has shown that optimizing these parameters can enhance the overall efficiency and reliability of pumps operating at high pressures. Furthermore, studies on innovative pump designs reveal that the transient flow field characteristics can be manipulated to improve performance in challenging conditions, underscoring the necessity of detailed evaluation when selecting a pump for specific industrial needs.

Maintenance Tips to Enhance the Lifespan of Your Chemical Pump

When selecting a chemical pump for industrial applications, longevity and efficiency are paramount. Regular maintenance is essential in prolonging the lifespan of your chemical pump and ensuring optimal performance. According to a report from the Hydraulic Institute, nearly 40% of pump failures can be traced back to inadequate maintenance practices. Therefore, implementing a robust maintenance schedule is critical for avoiding unexpected downtime and costly repairs.

One of the key maintenance tips is to perform routine inspections to monitor seals, bearings, and impellers for any signs of wear and tear. A study by the American Society of Mechanical Engineers suggests that a proactive approach can extend the operational life of pumps by up to 50%. Additionally, recalibrating pump flow rates and pressures periodically helps maintain efficiency and reduces the risk of cavitation, which can severely damage pump components. Regularly cleaning filters and ensuring proper lubrication also contribute significantly to the longevity of the pump, making these practices indispensable in any industrial setting. Keeping thorough maintenance records will further aid in identifying trends and potential issues before they escalate, allowing for timely intervention.

Efficiency of Chemical Pumps by Type

Calculating Total Cost of Ownership for Chemical Pumps in Operations

When selecting a chemical pump for industrial operations, understanding the total cost of ownership (TCO) is crucial. TCO encompasses not only the initial purchase price but also ongoing operational and maintenance costs. Factors such as energy consumption, frequency of maintenance, and the expected lifespan of the pump all contribute to this comprehensive financial picture. For instance, a less expensive pump may have higher energy usage or require more frequent repairs, ultimately leading to greater costs over time.

Additionally, the TCO should factor in the costs associated with unintended downtime caused by pump failures. An efficient pump with lower failure rates can significantly reduce lost production time, thereby enhancing overall operational efficiency. Moreover, the impact of chemical compatibility and corrosion rates on pump longevity should not be overlooked, as these can affect maintenance schedules and replacement cycles. By thoroughly evaluating these aspects, industrial operators can make informed decisions that align with both their budget and their efficiency goals.