How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance

In the rapidly evolving realm of micro pumps, selecting the right device is critical for achieving optimal performance across various applications. Industry expert Dr. Emily Chen, a renowned figure in fluid dynamics, emphasizes the importance of precision in her statement: "The right micro pump not only enhances efficiency but also ensures the desired flow characteristics are met." As micro pumps become integral to sectors such as medical devices, pharmaceuticals, and chemical processing, understanding the key factors that influence their selection is vital for successful implementation.

Choosing the appropriate micro pump involves a thorough assessment of various parameters, including the required flow rate, pressure, and compatibility with the fluids being handled. Additionally, advancements in technology continue to shape the landscape of micro pump design, leading to more sophisticated and reliable options. By delving into industry insights and expert opinions, stakeholders can navigate the complexities of micro pump selection more effectively, ensuring they make informed decisions that can significantly impact their operational success.

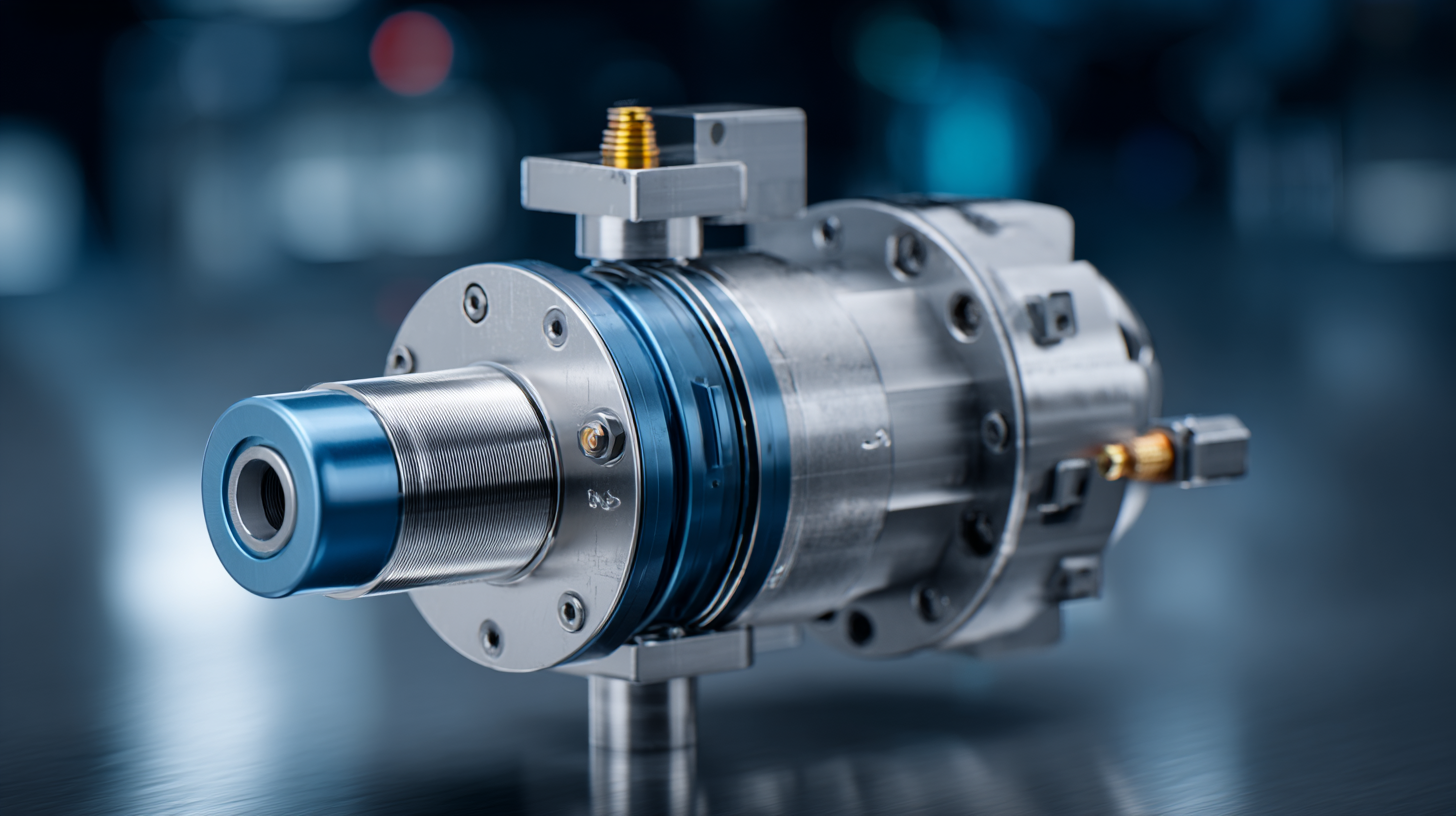

Understanding Micro Pump Types and Their Applications

Micro pumps are essential components in various industries, ranging from pharmaceuticals to automotive applications. Understanding the different types of micro pumps, such as peristaltic, diaphragm, and gear pumps, is crucial for selecting the optimal solution for specific applications. Peristaltic pumps, for instance, are highly regarded for their ability to handle viscous fluids and are widely used in medical devices, with market growth projected at approximately 10% annually, according to a recent report by MarketsandMarkets.

In addition, diaphragm pumps are known for their reliability and ability to handle corrosive fluids, making them ideal for chemical processing industries. According to research by Technavio, the diaphragm pump segment alone is expected to reach a market value of $5 billion by 2025, driven by the increasing demand for accurate fluid delivery. Gear pumps, on the other hand, offer high precision in applications such as inkjet printing and fuel dispensing, reflecting a growing trend towards automation and efficiency in manufacturing processes.

Choosing the right micro pump requires careful consideration of these types, their operational mechanisms, and application suitability. With a thorough understanding of micro pump applications, manufacturers can ensure optimal performance and enhance operational effectiveness in their respective sectors.

Key Performance Metrics to Consider for Micro Pumps

When selecting the right micro pump, it's crucial to focus on key performance metrics that directly influence its efficiency and application suitability. One primary metric to consider is the flow rate, which quantifies the volume of fluid that the pump can move in a given period. Depending on your application, whether it's in medical devices or industrial processes, the required flow rate can vary significantly.

Understanding the specific demands of your intended use will help you select a micro pump that can consistently meet performance requirements.

Another essential factor is pressure generation, often measured in psi or bar. Micro pumps must not only deliver the required fluid but also do so against varying pressures within the system. Evaluating the pump's pressure capabilities ensures it can function reliably under expected conditions. Additionally, examining the pump's compatibility with different fluids—taking into account factors like viscosity and chemical reactivity—further informs your choice, ultimately leading to optimal performance aligned with the needs of your project.

Factors Influencing Micro Pump Efficiency and Reliability

When selecting a micro pump, understanding the factors influencing its efficiency and reliability is crucial. One key aspect is the design and materials used in the pump construction. High-quality materials resist corrosion and wear, which is particularly important in applications involving aggressive fluids. Additionally, the pump's design must accommodate the specific fluid dynamics to minimize losses and improve flow rates, making it vital to consider geometrical parameters such as channel dimensions and pump orientation.

Another significant factor is the operational parameters, including pressure and flow requirements. Selecting a micro pump that matches the application's operational range ensures optimal performance and longevity. Furthermore, the type of driving mechanism—whether diaphragm, peristaltic, or gear—can dramatically impact the pump’s reliability. Each mechanism comes with distinct advantages and limitations, so understanding the application context is essential for making an informed choice. Finally, regular maintenance and monitoring of pump performance can significantly enhance reliability, identifying potential issues before they result in failures.

Comparative Analysis of Popular Micro Pump Brands and Models

When selecting the right micro pump, it's essential to understand the landscape of popular brands and models to ensure optimal performance for your specific application. According to industry reports, the micro pump market is projected to grow at a CAGR of 12.3% from 2021 to 2027, driven by advancements in medical devices and biotechnology applications. Leading brands such as Cole-Parmer, Micropump, and Onyx offer a variety of models catering to different needs. Cole-Parmer’s Masterflex peristaltic pumps are renowned for their reliability and easy maintenance, making them a go-to for laboratory use.

A comparative analysis reveals that Micropump’s gear pumps are particularly favored in the pharmaceutical industry due to their precision and robustness in high-viscosity applications. Furthermore, Onyx’s latest diaphragm pumps are gaining traction in the automotive sector for their compact design and efficiency. According to a recent survey conducted by MarketsandMarkets, 65% of survey respondents reported that ease of integration and reliability were the top factors influencing their choice of micro pumps, highlighting the importance of considering both performance and compatibility with existing systems.

How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance

| Dimension | Value A | Value B | Value C |

|---|---|---|---|

| Flow Rate (mL/min) | 50 | 30 | 75 |

| Max Pressure (bar) | 2.5 | 1.5 | 3.0 |

| Voltage (V) | 12 | 24 | 5 |

| Power Consumption (W) | 10 | 6 | 15 |

| Weight (kg) | 0.5 | 0.7 | 0.3 |

| Material Compatibility | Polypropylene | Glass | Silicone |

Industry Trends Shaping the Future of Micro Pump Technologies

The landscape of micro pump technologies is undergoing significant transformation influenced by various industry trends. According to recent reports, the global dispensing system market is expected to grow from USD 56.5 billion in 2025 to USD 108.1 billion by 2035, reflecting a robust compound annual growth rate (CAGR) of 6.7%. This growth is largely driven by advancements in water management practices, with micro pumps playing a vital role in improving efficiency and precision in fluid handling applications.

Furthermore, the microirrigation systems market is experiencing a similar upward trajectory, anticipated to increase from USD 10.4 billion in 2022 to USD 17.8 billion by 2028. The integration of innovative technologies, such as 3D printing for micro-nano device manufacturing, is enhancing the capabilities and approaches within this sector, offering new avenues for application in agriculture and beyond. As companies adapt to these changes, understanding the trends shaping the future of micro pump technologies will be crucial for optimizing performance and ensuring sustainable growth.

Micro Pump Market Trends and Performance Factors

Related Posts

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance