Best Chemical Injection Pump Types For Your Needs?

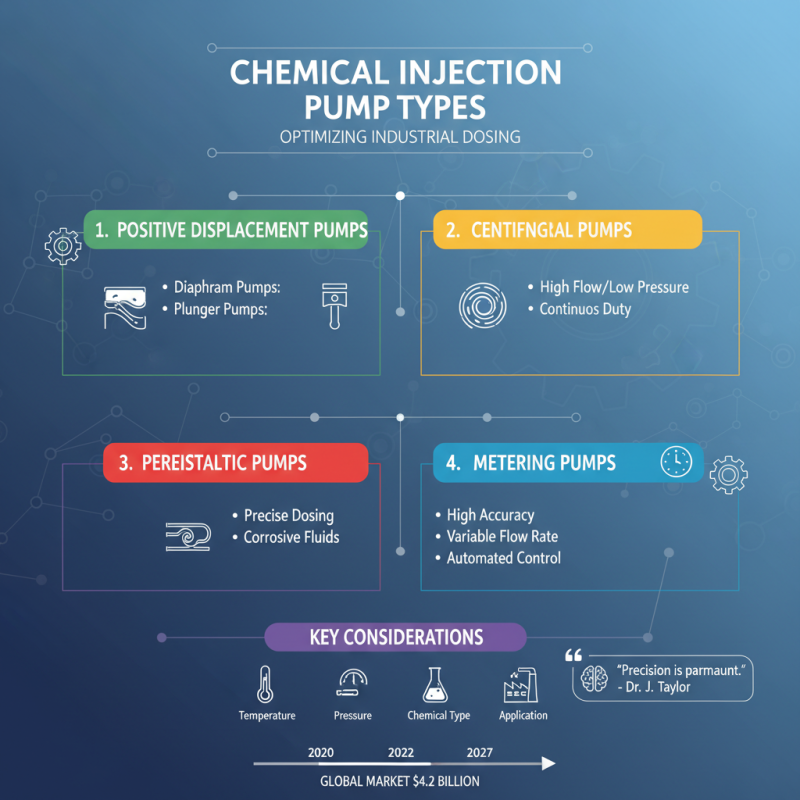

In the ever-evolving field of industrial applications, choosing the right chemical injection pump is crucial. Experts estimate that the global chemical injection pump market will reach $4.2 billion by 2027, reflecting a growing need for precision in chemical dosing. As Dr. John Taylor, a leading expert in fluid dynamics, puts it, "Selecting the proper chemical injection pump can drastically influence operational efficiency and safety."

Chemical injection pumps vary in design and functionality, each serving unique requirements across various industries. For example, industries such as oil and gas, water treatment, and food processing have specific needs that demand reliable and efficient pumping solutions. The diversity in pump types can be overwhelming, leading many to overlook specific attributes vital for their operations.

Moreover, not all pumps withstand harsh environments. Certain models may falter under extreme pressure or temperature. This realization is pivotal for making informed purchasing decisions. Acknowledging these complexities ensures that businesses find the best fit, aligning their operational goals with the right chemical injection pump technology.

Types of Chemical Injection Pumps: An Overview

Chemical injection pumps come in various types, each serving unique roles across industries. These pumps ensure precise chemical dosing, vital for processes in wastewater treatment, oil and gas, and agricultural sectors. According to a report by Grand View Research, the global chemical injection market is projected to reach $14.42 billion by 2026. This growth underscores the importance of selecting the right pump type for specific applications.

Diaphragm pumps are popular due to their ability to handle corrosive fluids. They provide reliable flow rates and are easy to maintain. Gear pumps, on the other hand, excel in high pressure applications. They ensure consistent delivery but may require more complex control systems. Peristaltic pumps have gained popularity in sensitive environments. Their design minimizes contamination risks. Yet, they may struggle with viscous fluids or require frequent tube replacements.

Choosing the right pump isn't always straightforward. Factors such as fluid characteristics, system pressure, and flow rate must be carefully evaluated. A 2020 survey indicated that 30% of users faced challenges in selecting appropriate pump types. Identifying the best fit involves not just understanding your needs, but also reflecting on the limitations of each system. Balancing efficiency and cost can be daunting, and the right choice can significantly impact operational success.

Key Factors to Consider When Selecting a Chemical Injection Pump

When selecting a chemical injection pump, several key factors can greatly impact your decision. Consider the type of fluid you will be handling. Viscous liquids require pumps designed for higher pressure and flow rates. Conversely, low-viscosity liquids can use simpler pumps. Understanding the specific characteristics of your chemical is crucial for efficiency.

Next, think about the required flow rate and pressure. Different applications demand various capacities. The pump must meet these specifications. You might find it helpful to measure your current requirements over time. This could reveal inconsistencies or needs you didn’t anticipate at first. Remember, using the wrong flow rate can lead to inefficiencies or failures.

Don’t overlook the environment where the pump will be installed. Factors like temperature, humidity, and exposure to corrosive elements play a vital role. Ensure that the materials used in the pump can withstand these conditions. Sometimes, it’s easy to assume all pumps are created equal. However, many pumps struggle in extreme conditions. Taking the time to assess your environment can save you from future issues.

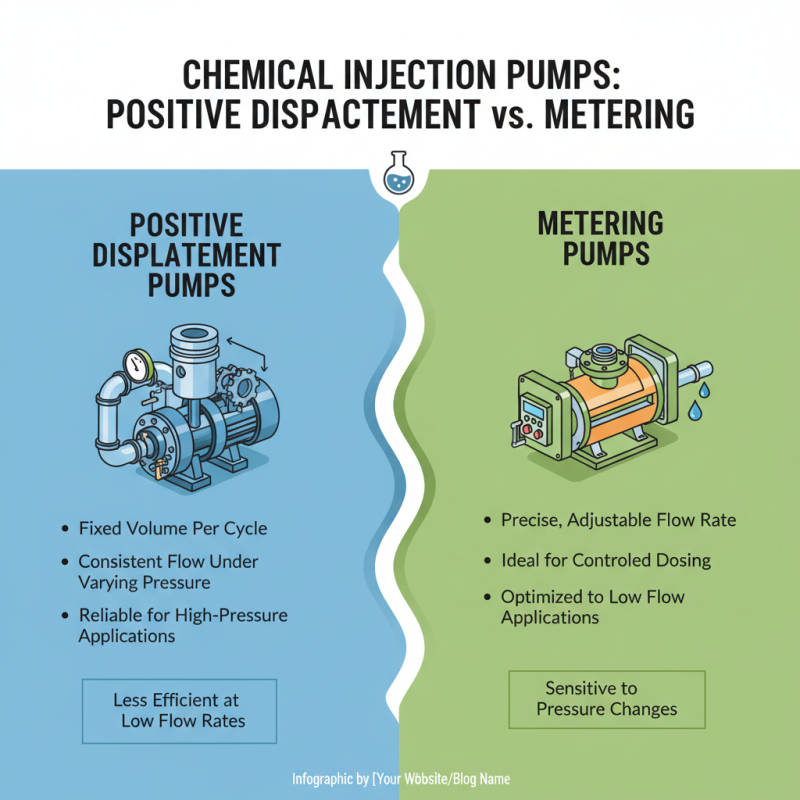

Comparison of Positive Displacement and Metering Pumps

When selecting a chemical injection pump, understanding the differences between positive displacement and metering pumps is crucial. Positive displacement pumps move a fixed volume of fluid with each cycle. They work effectively under varying pressures and provide a consistent flow rate. Many industries prefer these for their reliability in high-pressure applications. However, they can be less efficient at lower flow rates. This can lead to wasted energy or unnecessary wear and tear.

Metering pumps, on the other hand, provide precise flow rates. They adjust easily to changes in pressure and are ideal for accurate chemical dosing. This precision allows for better control over chemical use, reducing waste. Yet, metering pumps may struggle with high-viscosity fluids. The wear on components can also increase maintenance needs. Users must consider these trade-offs when making a decision.

Choosing between these types often requires careful consideration. Assess your application needs and the characteristics of your fluids. Sometimes, the best option isn't clear-cut. A pump that excels in one area may fall short in another. Taking the time to analyze your specific requirements will lead to better long-term outcomes.

Applications of Chemical Injection Pumps in Various Industries

Chemical injection pumps play a vital role in various industries. In oil and gas, these pumps ensure precise chemical dosing. They help in enhancing oil recovery and reducing pipeline corrosion. This results in improved efficiency and lower operational costs. In water treatment, chemical injection pumps are crucial. They introduce necessary chemicals for disinfection and purification. This ensures clean water for communities.

In agriculture, these pumps are used for fertilization. They provide nutrients directly to the crops, promoting healthy growth. However, improper calibration can lead to over or under-fertilization. This may affect crop yield adversely. In pharmaceuticals, precision is key. These pumps help in the accurate blending of substances. The process must be controlled to ensure product safety. Mistakes here can lead to significant consequences.

Each application requires a specific type of pump. Understanding the requirements is essential. Many users overlook the importance of regular maintenance. Neglecting this can lead to pump failure and increased costs. When selecting a chemical injection pump, consider your specific needs carefully. This can enhance performance and reduce risks in any operation.

Applications of Chemical Injection Pumps in Various Industries

Maintenance Tips for Ensuring Optimal Pump Performance

Proper maintenance is crucial for maintaining optimal performance in chemical injection pumps. A recent industry report indicated that nearly 30% of pump failures are due to insufficient maintenance. Regular checks can prevent such issues.

One critical tip is to regularly inspect seals and connections. Small leaks can lead to significant losses and safety hazards. Additionally, keep an eye on the pump’s performance metrics. For example, fluctuations in flow rate can signal underlying problems. Addressing these minor issues promptly can save time and costs down the line.

Another essential practice involves cleaning the pump components. Residues can build up and cause inefficiencies. Use appropriate cleaning agents suited to your pump type. However, do not overlook the manufacturer’s guidelines. Neglecting these details when cleaning can lead to pump damage and void warranties. Always remember: proactive maintenance is better than reactive repairs. Address your pump's needs before they escalate.

Best Chemical Injection Pump Types For Your Needs

| Pump Type | Best Application | Flow Rate (GPH) | Pressure Range (PSI) | Maintenance Frequency |

|---|---|---|---|---|

| Diaphragm Pump | Chemical dosing in wastewater | 1-50 GPH | 0-150 PSI | Monthly |

| Gear Pump | High viscosity chemical transfer | 0.5-25 GPH | 0-250 PSI | Quarterly |

| Peristaltic Pump | Pharmaceutical applications | 0.1-100 GPH | 0-100 PSI | Monthly |

| Centrifugal Pump | Large scale chemical process | 5-500 GPH | 0-300 PSI | Semi-annual |

| Progressive Cavity Pump | Sludge and slurry pumping | 1-60 GPH | 0-150 PSI | Monthly |

Related Posts

-

Top Benefits of Using Chemical Injection Pumps in Industrial Applications

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

-

The Future of Battery Pumps Revolutionizing Efficiency in Power Tools

-

Understanding the Importance of Lab Pumps in Modern Scientific Research

-

2025 How to Pump Direct: Tips for Maximizing Your Output Efficiently