Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

In recent years, the adoption of motor driven diaphragm pumps has surged across various industrial applications, driven by their unparalleled efficiency and reliability. According to a report by Grand View Research, the global diaphragm pump market is projected to reach USD 5.4 billion by 2025, growing at a CAGR of 5.2%. This growth is largely attributed to the versatility of motor driven diaphragm pumps, which can handle a wide range of fluids—from viscous liquids to slurries—while maintaining precise flow control. Furthermore, data from Transparency Market Research highlights that these pumps are increasingly being favored for their low maintenance requirements and ability to operate under harsh conditions, making them ideal for industries such as chemical processing, water treatment, and pharmaceuticals. As businesses prioritize sustainability and operational efficiency, understanding the myriad benefits of motor driven diaphragm pumps becomes essential for optimizing industrial processes.

In recent years, the adoption of motor driven diaphragm pumps has surged across various industrial applications, driven by their unparalleled efficiency and reliability. According to a report by Grand View Research, the global diaphragm pump market is projected to reach USD 5.4 billion by 2025, growing at a CAGR of 5.2%. This growth is largely attributed to the versatility of motor driven diaphragm pumps, which can handle a wide range of fluids—from viscous liquids to slurries—while maintaining precise flow control. Furthermore, data from Transparency Market Research highlights that these pumps are increasingly being favored for their low maintenance requirements and ability to operate under harsh conditions, making them ideal for industries such as chemical processing, water treatment, and pharmaceuticals. As businesses prioritize sustainability and operational efficiency, understanding the myriad benefits of motor driven diaphragm pumps becomes essential for optimizing industrial processes.

The Role of Motor Driven Diaphragm Pumps in Enhancing Fluid Transfer Efficiency

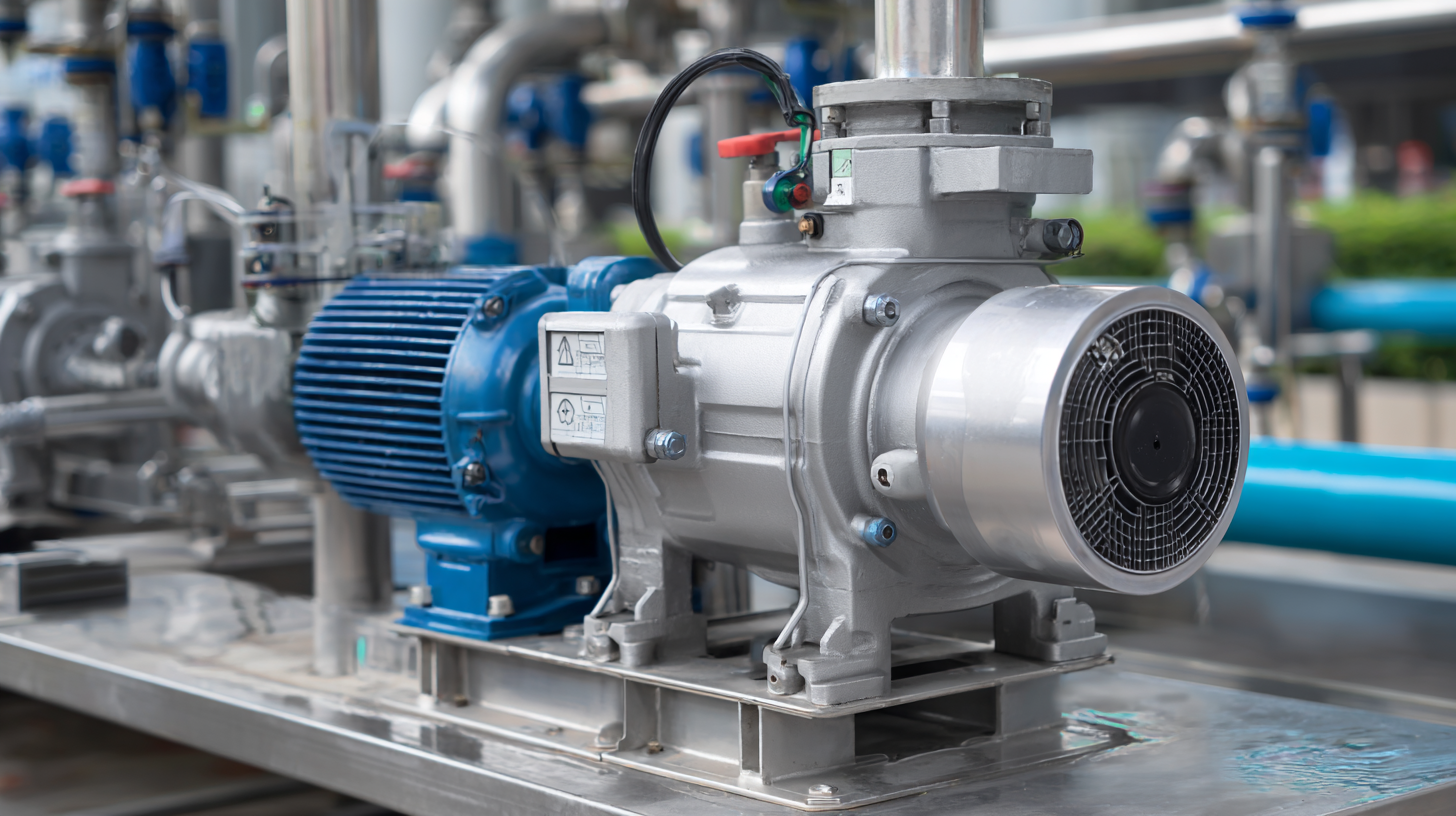

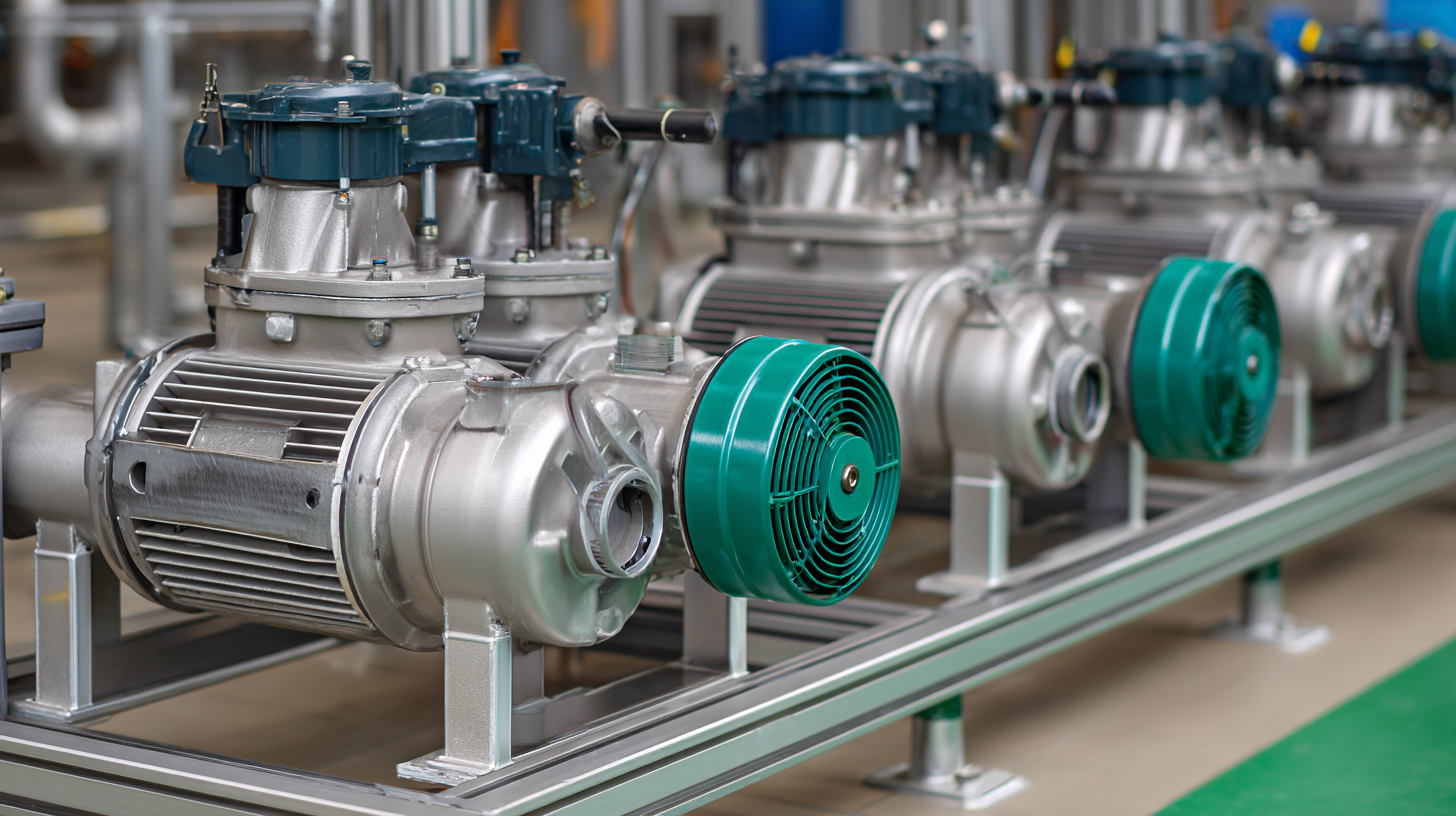

Motor driven diaphragm pumps play a crucial role in enhancing fluid transfer efficiency across various industrial applications. These pumps utilize a diaphragm mechanism that allows them to handle a wide range of fluids, including corrosive and viscous materials. The motor-driven aspect ensures a consistent and controlled flow rate, significantly improving the overall performance of fluid transfer systems. With the ability to maintain precise pressure levels and eliminate pulsations, these pumps are ideal for tasks requiring accuracy and reliability.

**Tips:** When selecting a motor driven diaphragm pump, consider the specific fluid properties such as viscosity and chemical compatibility to ensure optimal performance. Regular maintenance is essential to prolong the lifespan of the pump and maintain efficiency. Additionally, incorporating a pressure relief valve can prevent overpressure situations, safeguarding both the pump and the system.

These pumps also provide the advantage of easy installation and low maintenance requirements. Their compact design and versatility allow them to fit in various setups, making them a preferred choice in industries ranging from pharmaceuticals to wastewater treatment. With advancements in technology, modern motor driven diaphragm pumps come equipped with features such as monitoring systems that further enhance their efficiency and usability in complex processes.

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

| Dimension | Details |

|---|---|

| Type of Pump | Motor Driven Diaphragm Pump |

| Flow Rate Range | 0.5 - 100 GPM |

| Efficiency Rate | Up to 90% |

| Applications | Chemical transfer, water treatment, food and beverage processing |

| Material Compatibility | PVC, PTFE, Stainless Steel |

| Power Supply | Electric Motor (Single Phase/Three Phase) |

| Maintenance Needs | Low Maintenance; Periodic inspection recommended |

| Key Benefits | Leak-proof operation, high efficiency, consistent performance |

Comparative Analysis: Diaphragm Pumps vs. Traditional Pump Technologies

When comparing diaphragm pumps with traditional pump technologies, a notable distinction lies in their operational efficiency and versatility. Traditional pumps, such as centrifugal and positive displacement pumps, are often limited by their design and application scope. For example, centrifugal pumps may struggle with viscous fluids or slurry applications, leading to inefficient performance. In contrast, diaphragm pumps can handle a wide range of fluids, including corrosive and abrasive materials, without risking contamination. This flexibility makes them an ideal choice for various industrial applications.

Moreover, diaphragm pumps offer superior reliability and maintenance benefits. Traditional pumps may require frequent seal replacements and repairs due to wear and tear, which can lead to costly downtime. Diaphragm pumps, characterized by their sealed design and lack of moving parts in contact with the fluid, minimize maintenance needs and extend operational life. This reduces not only the maintenance costs but also the chances of leaks, ensuring a safer working environment. Thus, in industries where reliability and efficiency are paramount, diaphragm pumps emerge as a more advantageous alternative to traditional pumping solutions.

Industry Statistics: Cost Savings through Reduced Maintenance with Diaphragm Pumps

In industrial applications, the efficiency and reliability of pumps are critical to maintaining operational integrity. Motor driven diaphragm pumps have gained traction primarily due to their ability to significantly reduce maintenance costs. By employing a simple yet robust design, these pumps minimize wear and tear, leading to extended maintenance intervals. This reduction in maintenance requirements translates to substantial cost savings for businesses, allowing them to allocate resources towards other operational needs.

Recent industry statistics highlight the financial advantages of transitioning to diaphragm pumps. Companies that have made the switch report a decrease in downtime and a notable reduction in maintenance-related expenses. The self-priming nature of these pumps and their capability to handle viscous and abrasive fluids without damage further contribute to their favorable performance profiles. This reliability not only supports continuous production processes but also enhances overall productivity by minimizing interruptions related to service and repairs.

Applications in Chemical Processing: Why Diaphragm Pumps are the Preferred Choice

Diaphragm pumps have emerged as the preferred choice in chemical processing applications due to their significant advantages in handling a variety of fluids safely and efficiently. The metering pumps market is projected to reach USD 9.1 billion by 2030, indicating a growing trend towards precise fluid management in industrial sectors. Diaphragm pumps offer superior chemical compatibility, making them ideal for transporting hazardous substances while minimizing the risk of leaks and contamination.

Recent advancements in diaphragm pump technology, such as the introduction of single-use pumps with innovative safety features, enhance their viability for pharmaceutical applications and other sensitive environments. As the chemical injection pump industry anticipates a decade-long expansion, driven by increased industrial dosing applications, the reliability and flexibility of diaphragm pumps will be critical.

Reports indicate that the global dosing pump market is expected to grow at a CAGR of 5.3% from 2025 to 2033, reflecting the rising demand for efficient and safe pumping solutions in chemical processing and beyond.

Safety Benefits: Minimizing Risk with Leak-Free Diaphragm Pump Operations

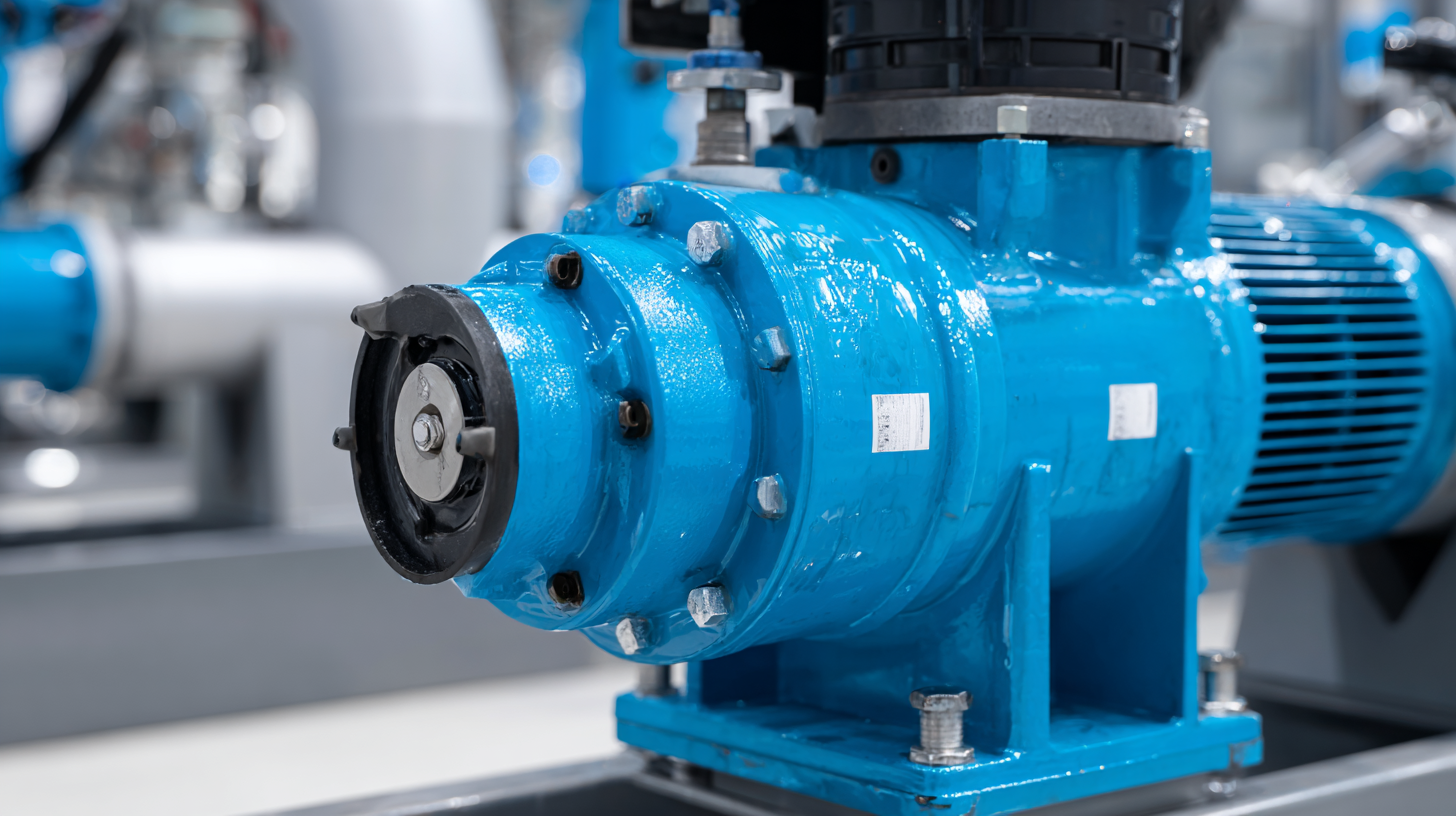

Motor driven diaphragm pumps are increasingly recognized for their safety benefits in industrial applications, particularly due to their leak-free operation. By utilizing a flexible diaphragm, these pumps effectively separate the pumped fluid from the mechanical components, significantly reducing the risk of leaks. This feature is particularly crucial when handling hazardous chemicals or sensitive materials, where even minor leaks can lead to severe environmental and safety issues.

In addition to containing potential spills, leak-free operations enhance overall workplace safety. The design of motor driven diaphragm pumps minimizes exposure to harmful substances for workers, helping to maintain a healthier work environment. These pumps also eliminate the need for expensive containment systems that are often necessary for traditional pump designs prone to leaks. By prioritizing safety and efficiency, motor driven diaphragm pumps not only protect the workforce but also contribute to compliance with stringent environmental regulations, making them an increasingly preferred choice in various industrial sectors.

Related Posts

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

The Future of Battery Pumps Revolutionizing Efficiency in Power Tools

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Understanding the Benefits of a Food Pump for Home Cooking Efficiency