Top Benefits of Using Chemical Injection Pumps in Industrial Applications

In the realm of industrial applications, the efficiency and reliability of chemical handling have become paramount. The utilization of chemical injection pumps is increasingly recognized as a critical component in various sectors, including oil and gas, water treatment, and chemical manufacturing. According to a report by Research and Markets, the global market for chemical injection pumps is projected to reach USD 4.5 billion by 2025, driven by the escalating demand for efficient pumping solutions and the expansion of infrastructure in emerging economies.

Chemical injection pumps provide precise and controlled delivery of chemicals, which is essential for processes that require accurate dosing and regulation. This is particularly important given the stringent regulatory standards for environmental safety and operational efficiency. In fact, a study from the International Journal of Chemical Engineering noted that improper chemical handling can lead to significant operational disruptions, increased costs, and potential environmental hazards. Thus, integrating chemical injection pumps into industrial operations not only enhances productivity but also mitigates risks associated with chemical handling.

Additionally, the adaptability and versatility of chemical injection pumps make them suitable for a myriad of applications ranging from petrochemical processes to wastewater treatment systems. With advancements in technology, these pumps are now equipped with automated features that improve monitoring and maintenance, further underscoring their value in modern industrial applications. By leveraging the benefits of chemical injection pumps, industries can optimize their operations while ensuring safety and compliance with industry regulations.

Benefits of Enhanced Accuracy and Control in Chemical Injection Pumps

Chemical injection pumps play a crucial role in various industrial applications, particularly in enhancing accuracy and control. These pumps allow for precise dosing of chemicals into processes, ensuring that exact quantities are delivered. This precision not only increases operational efficiency but also helps in maintaining product quality and minimizing waste. With the ability to adjust injection rates dynamically, industries can optimize their chemical usage based on real-time data, resulting in cost savings and improved environmental compliance.

When integrating chemical injection pumps, it is vital to focus on system calibration and monitoring. Regularly calibrating the equipment ensures that the chemical delivery remains accurate over time. Additionally, incorporating sensors for pressure and flow can provide real-time feedback, allowing for adjustments that enhance overall performance.

Tips: Always ensure that your chemical injection system is equipped with fail-safes to prevent over-injection, which can lead to process complications. Also, consider investing in training for your team to ensure they are familiar with best practices for operating and maintaining these systems effectively. Regular maintenance and inspections can prevent costly downtimes and extend the lifespan of the equipment.

Improved Operational Efficiency and Cost Reduction in Chemical Processing

Chemical injection pumps play a crucial role in enhancing operational efficiency within industrial applications, particularly in the realm of chemical processing. By automating the precise delivery of chemicals, these pumps eliminate the risk of human error and ensure consistent dosing. This accuracy not only maximizes the effectiveness of the chemicals used but also minimizes waste, significantly lowering operational costs over time. The ability to program these pumps to meet specific production schedules further streamlines processes, allowing facilities to optimize their workflows and reduce downtime.

In addition to improving efficiency, chemical injection pumps contribute to substantial cost reduction. By using less chemical volume through precise dosing techniques, companies can conserve resources and reduce their overall expenditure on materials. The reliability of these pumps also means that maintenance costs are lowered, as they are designed for durability and longevity. Furthermore, reducing the frequency of manual interventions decreases labor costs and minimizes safety risks associated with chemical handling. Overall, the integration of chemical injection pumps into industrial processes leads to a more sustainable and economical approach to chemical processing.

Minimized Downtime Through Reliable Chemical Injection Systems

Reliable chemical injection systems are crucial for minimizing downtime in industrial applications, particularly in oil and gas, water treatment, and chemical production sectors. According to a recent report by the International Journal of Chemical Engineering, facilities that implement automated chemical injection pumps report a reduction in unscheduled downtimes by up to 30%. This enhancement in reliability stems from the precision and consistency these systems provide, allowing industries to maintain optimal operational efficiency without the frequent interruptions caused by manual injection methods.

Furthermore, the increasing complexity of industrial processes necessitates a robust chemical management strategy. Research published by the Society of Petroleum Engineers highlights that nearly 20% of production losses are attributable to inefficient chemical handling. By utilizing advanced chemical injection pumps, operators can achieve a more accurate dosage of chemicals, minimizing waste and ensuring effective treatment that directly correlates with increased uptime. This strategic shift not only supports environmental sustainability by reducing the amount of chemicals released into ecosystems but also significantly enhances profitability by maximizing production output.

Environmental Compliance and Safety Standards in Industrial Applications

In industrial applications, adhering to environmental compliance and safety standards is paramount, and chemical injection pumps play a vital role in achieving these goals. These pumps facilitate accurate dosing and distribution of chemicals, minimizing the risk of spills or leaks that can harm the environment. By ensuring consistent application rates, they help industries maintain regulatory compliance while also promoting safe operations.

When selecting chemical injection pumps, it is crucial to consider factors such as material compatibility and safety features. Pumps constructed from corrosion-resistant materials not only enhance durability but also prevent chemical reactions that could lead to hazardous situations. Additionally, incorporating safety mechanisms, like automatic shut-off systems, can further reduce the likelihood of accidents and mitigate risks associated with handling potentially dangerous substances.

Tips: Regular maintenance and monitoring of chemical injection pumps are essential in maintaining compliance with environmental standards. Implementing routine checks can help identify wear and tear before it leads to operational failures, ultimately safeguarding both personnel and the ecosystem. Training staff on proper handling procedures and emergency response strategies will also play a critical role in ensuring safety within industrial environments.

Flexibility and Customization in Chemical Delivery Solutions for Industries

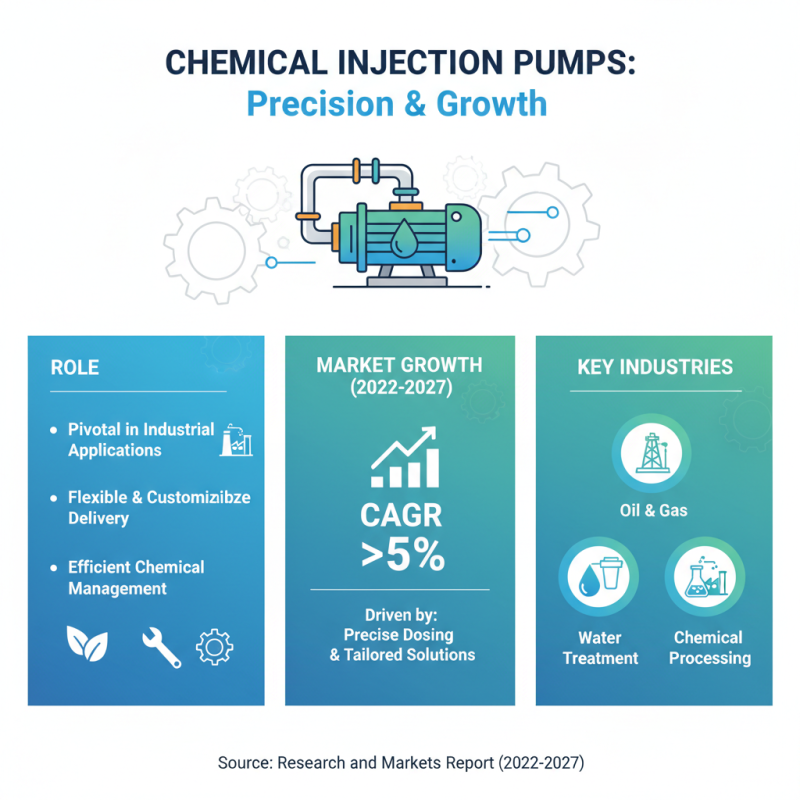

Chemical injection pumps play a pivotal role in various industrial applications by offering unparalleled flexibility and customization in chemical delivery solutions. According to a recent market report from Research and Markets, the global chemical injection pump market is expected to grow at a CAGR of over 5% from 2022 to 2027, highlighting the increasing importance of efficient chemical management in industries such as oil and gas, water treatment, and chemical processing. This growth is largely driven by the need for precise dosing and tailored solutions that adapt to specific operational requirements.

The ability to customize chemical delivery systems ensures that industries can optimize their processes and maintain regulatory compliance. For instance, industries that require varying chemical concentrations or differing flow rates can benefit from programmable injection pumps, which allow operators to adjust parameters based on real-time usage and conditions. This adaptability not only enhances operational efficiency but also minimizes waste and promotes sustainability. Data from the International Society for Automation indicates that implementing more flexible chemical injection systems can lead to reductions in chemical usage by up to 20%, significantly decreasing overall environmental impact.

Furthermore, the integration of advanced monitoring technologies in chemical injection pumps facilitates better oversight and control of chemical delivery. Industry studies have shown that real-time data analytics can improve decision-making and predictive maintenance, ultimately extending the lifespan of pumping equipment. As industries continue to innovate, the demand for chemical injection solutions that are both flexible and customizable will remain critical in ensuring functions are carried out efficiently and sustainably.

Related Posts

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

Understanding the Importance of Transfer Pumps in Everyday Life: A Complete Guide

-

Exploring the Benefits of Food Pumps for Efficient Culinary Experiences

-

Top 7 High Viscosity Pumps for Optimal Performance in Industrial Applications

-

Top 10 Battery Pumps for Efficient Water Transfer and Easy Usage

-

Why You Need a Laboratory Pump for Efficient Fluid Transfer