2026 Top Trends in Chemical Diaphragm Pump Technology and Innovations?

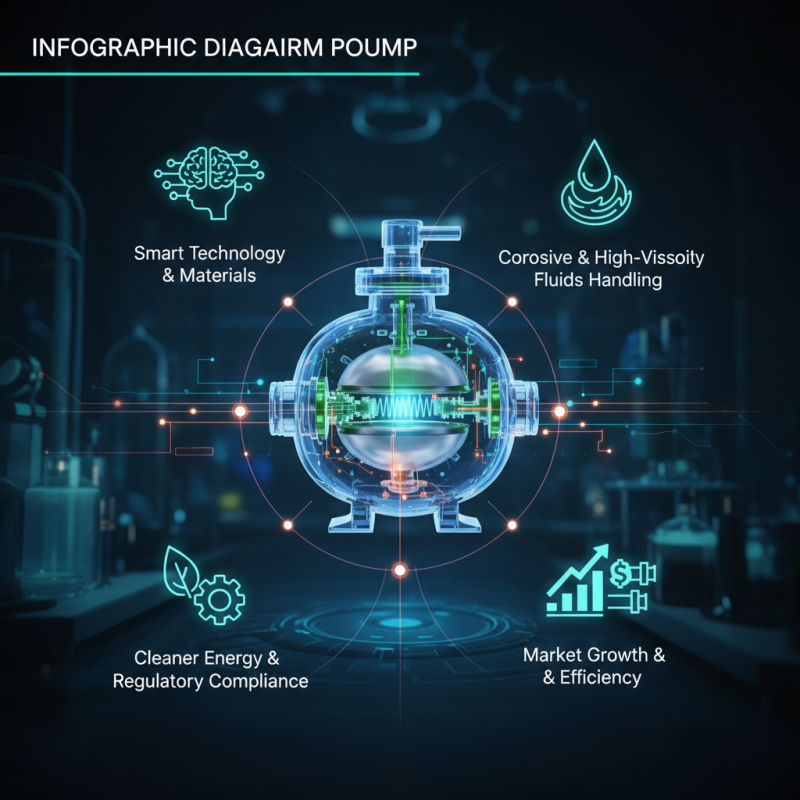

The landscape of chemical diaphragm pump technology is evolving rapidly. As industries demand higher efficiency and reliability, innovative designs are emerging. According to a recent market analysis by Global Industry Analysts, the global chemical diaphragm pump market is projected to reach $2.5 billion by 2026. This growth reflects the increasing need for precision in fluid management across various sectors.

Dr. Emily Carter, a renowned expert in the field, notes, “The advancements in chemical diaphragm pump technology are critical for ensuring safer and more efficient operations.” The integration of smart technology and materials is becoming more common. However, some challenges remain, like the adaptation of legacy systems to new innovations.

As we explore the top trends for 2026, it is vital to focus on these developments. Cleaner energy solutions and regulatory compliance are driving forces in this market. Moreover, the ability to handle corrosive and high-viscosity fluids remains a key factor. The journey ahead is marked by both promise and the need for thoughtful consideration of evolving industry demands.

Emerging Materials in Diaphragm Pump Manufacturing for 2026

The diaphragm pump industry is on the brink of exciting changes. New materials are vital in shaping the manufacturing landscape for 2026. Advanced thermoplastics and composite materials are gaining traction. These materials offer superior chemical resistance and durability, essential for various applications. In particular, lightweight alternatives enhance efficiency and performance.

Sustainability remains a pressing concern. Biodegradable materials are being explored. However, challenges exist in balancing performance with eco-friendliness. Some manufacturers struggle to find materials that perform well in extreme conditions. Research is ongoing, but results have been mixed. The transition to sustainable options proves to be complex.

Emerging technologies also influence material selection. 3D printing techniques enable more efficient designs. Yet, some engineers find limitations in the available biocompatible materials. The future is exciting, but uncertainties remain. Striking the perfect balance between innovation and practicality is critical. Innovation is not without its hurdles, and reflection is necessary to pave the way forward.

Advancements in Diaphragm Design for Enhanced Efficiency and Performance

In recent years, advancements in diaphragm design have revolutionized pump technology. These innovations focus on enhancing efficiency and performance across various applications. Manufacturers are experimenting with new materials and geometries to optimize the diaphragm's movement. This leads to less energy consumption, which is a game-changer in industrial settings.

One fascinating trend is the use of composite materials. These materials can be lighter and more durable than traditional options. By integrating these composites, pumps can handle higher pressures and aggressive fluids effectively. This improvement can boost operational reliability. However, the integration of new materials also poses challenges. Understanding their long-term performance in different environments is crucial for sustainability.

Another innovation lies in the design of the diaphragm itself. Advanced modeling techniques allow for precision engineering of diaphragm shapes. These designs improve fluid flow and minimize pulsation. However, achieving the perfect balance between flexibility and sturdiness remains difficult. Continuous testing is needed to identify potential weaknesses in various scenarios. Embracing these innovations, while being mindful of potential pitfalls, will shape the future of diaphragm pumps.

Innovations in Pump Control Technologies for Precision Applications

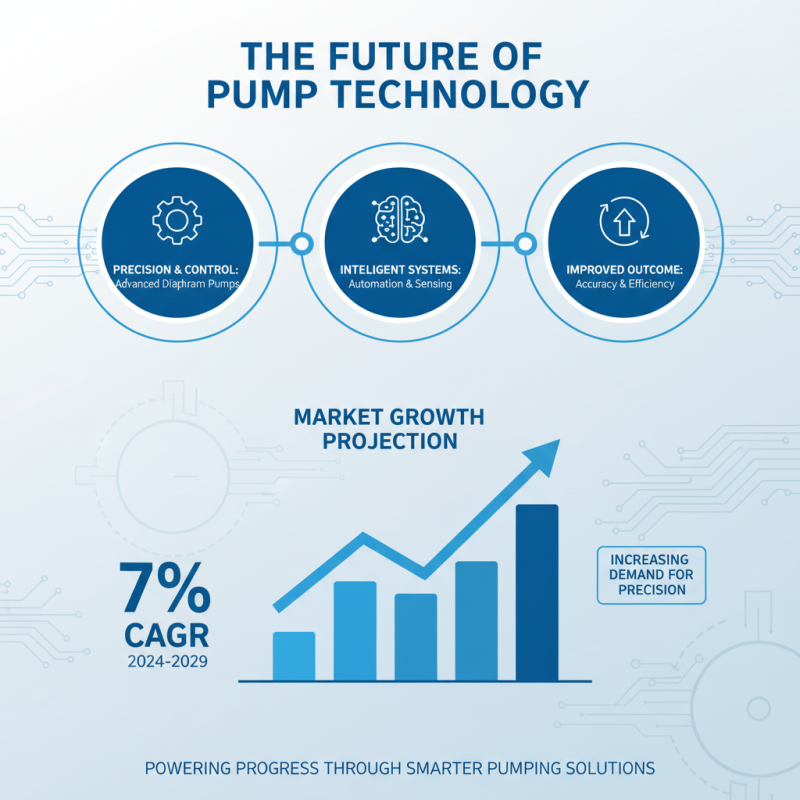

The future of pump technology is focusing on precision. Advanced control systems are enhancing the performance of diaphragm pumps. Innovations in automation and sensing technologies are paving the way for improved accuracy and efficiency. Reports show that the market for intelligent pump controls is expected to grow significantly, with a projected CAGR of 7% from 2024 to 2029. This highlights the increasing demand for precision applications.

Tips for optimizing pump control include regular monitoring. Implementing real-time data analytics tools can greatly enhance responsiveness. Make sure to evaluate existing software systems. Coordination between components is crucial for seamless operation. However, many manufacturers still face challenges with integration and compatibility. Keeping an updated database of pump specifications helps in making informed decisions.

Emerging technologies like IoT are shaping the landscape of pump control. Smart sensors can detect changes in flow rates instantaneously. This leads to better management of resources. However, not all systems are foolproof. Operators must be cautious of potential inaccuracies. Regular training and adherence to best practices can mitigate risks. Embracing these innovations is essential, but vulnerabilities remain.

Sustainability Trends in Chemical Diaphragm Pump Production

The production of chemical diaphragm pumps is increasingly emphasizing sustainability. Companies are exploring eco-friendly materials to reduce environmental impact. For instance, using recycled plastics can significantly lower carbon footprints. These materials are durable and can perform under varying chemical conditions.

Innovation in manufacturing processes is also crucial. Techniques such as 3D printing allow for precise designs while minimizing waste. However, this technology still faces challenges in scaling up production effectively. Moreover, not all manufacturers have access to the resources required for such technologies.

Transparency in sourcing materials is essential. Some suppliers may not disclose their environmental policies. This opacity can lead to ethical dilemmas for manufacturers seeking sustainability. In many cases, there may be a gap between commitment and actual practices. Consequently, continuous reflection on these processes is vital for true sustainability in chemical diaphragm pump production.

Integration of Smart Technologies in Diaphragm Pump Systems

The integration of smart technologies in diaphragm pump systems is shaping the future of fluid handling. According to a report by Research and Markets, the global diaphragm pump market is expected to witness a CAGR of 5.5% by 2026. This growth is driven by the adoption of IoT and advanced automation. Smart sensors now enhance performance monitoring and predictive maintenance, reducing downtime.

Real-time data analytics is crucial. Operators can monitor pump performance remotely, enabling quick responses to issues. This technology increases efficiency and reliability in various applications, from wastewater treatment to chemical processing. However, integrating these systems can be challenging. Companies must invest in training. Not all staff are familiar with advanced tech.

A major concern is cybersecurity. Connected devices are vulnerable to attacks. Securing data must remain a priority for manufacturers. Continuous innovation should focus not only on performance but also on safety measures. This industry must learn from past mistakes. Balancing technology and practicality will be key for successful integration in diaphragm pump systems.

2026 Top Trends in Chemical Diaphragm Pump Technology and Innovations

| Trend | Description | Impact | Year of Implementation |

|---|---|---|---|

| IoT Integration | Integration of Internet of Things technology for real-time monitoring and analytics. | Increased efficiency and decreased downtime through predictive maintenance. | 2026 |

| Artificial Intelligence | Utilization of AI for optimal operation adjustments and fault detection. | Enhanced process control leading to cost savings and resource optimization. | 2026 |

| Energy Efficiency | Development of energy-efficient diaphragm pump designs to reduce consumption. | Lower operational costs and reduced carbon footprint. | 2025 |

| Smart Sensors | Incorporation of advanced sensors for monitoring pressure, flow, and temperature. | Improved safety and system reliability. | 2025 |

| Remote Operation | Capabilities for remote operation and control through mobile applications. | Increased operational flexibility and responsiveness. | 2026 |

Related Posts

-

Understanding the Benefits of Motor Driven Diaphragm Pumps in Industrial Applications

-

Top 5 Chemical Diaphragm Pumps for Efficient Fluid Transfer in 2023

-

2026 How to Choose the Right Diaphragm Pump Diaphragm for Your Needs?

-

2026 Top Trends in Chemical Diaphragm Pumps to Watch Out For?

-

What is a Lab Pump and How Does It Work in Scientific Research

-

Top 7 High Viscosity Pumps for Optimal Performance in Industrial Applications