2026 Top Pump Solutions for Every Industry Need?

In today's diverse industries, finding the right pump solutions can be a daunting task. Each sector, from agriculture to manufacturing, has unique needs that demand innovative approaches. Industry expert Dr. Emily Carter once stated, "Effective pump solutions are the backbone of operational efficiency." This highlights the critical role that tailored pump systems play in enhancing productivity.

As we look toward 2026, the landscape of pump solutions evolves rapidly. New technologies emerge, promising greater reliability and energy efficiency. However, many companies still overlook the importance of selecting the appropriate pump for their specific applications. It's essential to recognize that a one-size-fits-all approach often leads to inefficiencies. Companies can benefit significantly from a customized strategy that matches their unique processes.

Moreover, the integration of smart technologies in pump solutions offers endless potential. Yet, some organizations struggle with understanding these advancements. This can result in missed opportunities and increased operational costs. Thus, pondering the right pump solutions not only requires technical knowledge but also a willingness to adapt and refine existing practices for future success.

Overview of Pump Solutions Across Industries

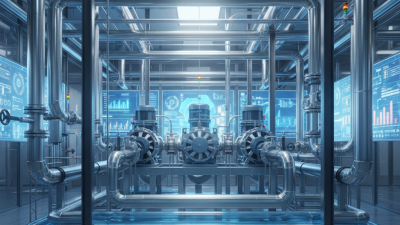

Pumps play a crucial role in diverse industries. Each sector has unique requirements. Understanding these needs helps in selecting the right solution. For instance, in the water treatment industry, efficient pump systems are vital for maintaining clean supplies. They must handle varying flow rates and pressures. This need often leads to complex engineering challenges.

In the oil and gas sector, pumps face harsh environments. They must resist corrosion and high temperatures. Selecting the right material becomes essential. Yet, many companies overlook regular maintenance. This neglect can lead to unexpected failures. Additionally, in agriculture, irrigation systems rely heavily on reliable pumps. However, improper installation can waste water and energy.

Manufacturers continue to innovate. Smart pumps with sensor technologies offer efficiency gains. But not all facilities embrace these advancements. Some may stick to outdated models. This creates a gap in performance. Such reflections can lead to better choices. Evaluation of existing systems is key to meeting industrial demands effectively.

2026 Top Pump Solutions for Every Industry Need

| Industry | Pump Type | Application | Flow Rate (m³/h) | Head (m) |

|---|---|---|---|---|

| Oil & Gas | Centrifugal Pump | Crude Oil Transfer | 150 | 80 |

| Water Treatment | Diaphragm Pump | Chemical Dosing | 20 | 10 |

| Chemical Processing | Gear Pump | Viscous Liquid Transfer | 30 | 15 |

| Food & Beverage | Progressive Cavity Pump | Food Paste Transfer | 50 | 20 |

| HVAC | Submersible Pump | Condensate Removal | 40 | 5 |

Key Factors in Selecting the Right Pump Type

When choosing a pump, it's vital to understand the specific requirements of your industry. Each sector has unique challenges. This can range from handling various fluid types to ensuring efficiency.

A food processing plant, for instance, requires pumps that are sanitary and easy to clean. In contrast, an oil rig needs pumps that can withstand high pressures and harsh conditions.

Consider the pump’s intended use. Will it be moving viscous liquids or slurries? How much flow rate do you require? You should also assess the energy efficiency of the pump. Some are designed to minimize energy consumption while maximizing output. Yet, not all pumps meet these criteria. It's essential to test their performance during real-world conditions.

Be wary of claims that seem too good to be true.

Maintenance is another critical factor. Choosing a pump is not just about initial purchase price. Long-term maintenance costs can add up. Understanding the level of maintenance each pump type requires is critical. Some might need frequent servicing, while others can run for years with minimal intervention.

Evaluate your team’s capability too. Sometimes, the best choice may not be the most obvious one.

Top Pump Technologies for Various Applications

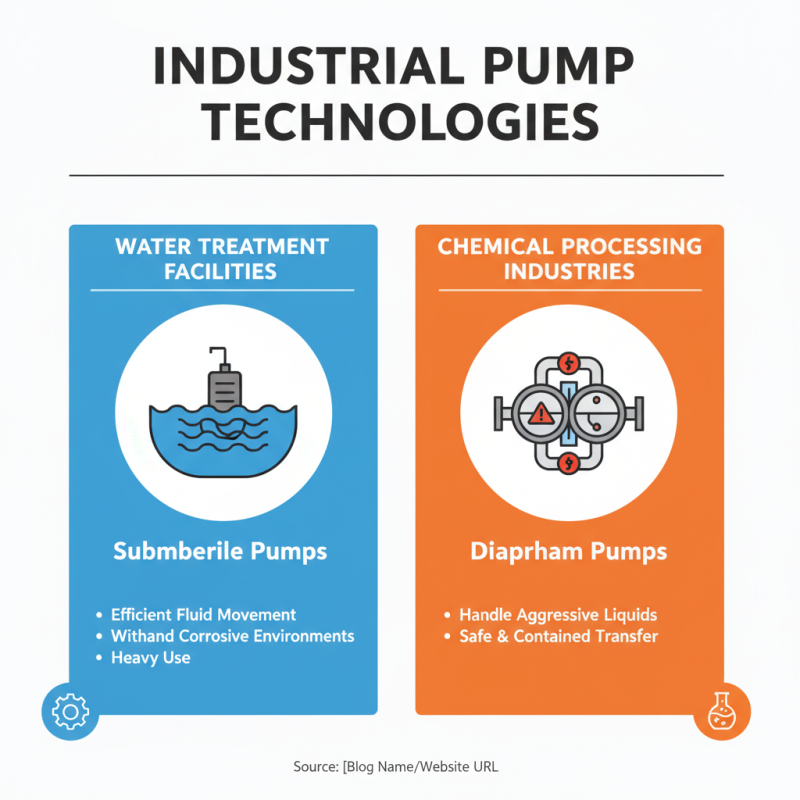

When it comes to pump technologies, different industries have unique needs. For instance, water treatment facilities often require submersible pumps for efficient fluid movement. These pumps need to withstand corrosive environments and heavy use. Similarly, chemical processing industries rely on diaphragm pumps to handle aggressive liquids safely.

Tips: Always consider the specific requirements of your application. Think about fluid type, temperature, and viscosity. This will guide you in selecting the right pump technology.

In the food and beverage industry, sanitary pumps play a crucial role. They ensure that hygiene standards are met while transporting products. If a pump is difficult to clean, it may lead to contamination, which can be costly. Evaluating ease of maintenance is vital.

Tips: Regular maintenance checks can prolong pump lifespan. Don’t ignore unusual noises or performance drops. These can signal underlying issues that need attention.

Future Trends in Pump Engineering and Design

The future of pump engineering is bright yet challenging. Engineers must adapt to evolving industry demands.

Innovative materials, such as composites, are gaining popularity. These materials can reduce weight and improve resistance to corrosion.

The use of smart technology is also on the rise. Sensors and IoT connectivity can enhance efficiency and provide real-time data.

Design trends are shifting towards modular systems. These systems offer flexibility and easier maintenance. They allow industries to scale without extensive overhauls.

However, not every design will fit every application. Customization can be a double-edged sword. It requires more time and resources, which some companies may lack.

Sustainability is a vital theme shaping pump design. Energy-efficient motors and environmentally friendly materials are essential.

Yet, balancing cost and sustainability remains a challenge. Feedback from users is often mixed. Some see benefits, while others struggle with higher initial costs.

This inconsistency forces engineers to rethink their strategies continuously. Embracing feedback is crucial for evolution in the industry.

Case Studies: Successful Pump Solutions in Different Sectors

In today's industrial landscape, pumps are integral to various operations. Case studies reveal diverse applications across multiple sectors. For instance, in the oil and gas industry, a report from the American Petroleum Institute states that nearly 70% of production relies on efficient pumping systems. These pumps manage crude oil extraction and transportation, showing their critical role in the supply chain.

In the chemical manufacturing sector, research indicates that improper pump selection can result in up to 40% higher maintenance costs. One facility improved output by 25% after implementing a new pump technology. This highlights the importance of tailoring solutions to specific industry needs. However, not all facilities achieve these gains. Many face issues like pump failures and inefficiencies, indicating a gap between potential and reality.

Meanwhile, in the wastewater treatment industry, a study found that inefficient pumps can lead to energy losses of up to 30%. By redesigning their pumping systems, one municipality reduced energy consumption by nearly 20%. Yet, many systems still struggle with outdated technologies. This emphasizes the need for continuous evaluation and innovation to meet evolving demands in every industry.

Related Posts

-

Why You Need Effective Pump Solutions for Your Business Efficiency

-

2025 How to Pump Direct: Tips for Maximizing Your Output Efficiently

-

Top Tips for Choosing the Best Well and Pump Systems in 2025

-

Why Are Micro Pumps Essential for Modern Technology Applications?

-

10 Essential Tips for Choosing the Right Sanitary Pumps for Your Needs

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency