2025 Top Lab Pump Innovations for Precision and Efficiency in Research

As the demand for precision and efficiency in research continues to rise, the laboratory equipment industry is witnessing groundbreaking innovations, particularly in the field of lab pumps. According to Dr. Emily Chen, an expert in fluid dynamics and lab automation, "The evolution of lab pump technology is pivotal for enhancing experimental accuracy and streamlining workflows in modern laboratories." This statement encapsulates the importance of reliable lab pumps in various research settings, where precision in fluid handling is critical.

The advancements in lab pump design over the next few years aim to improve not only the accuracy of measurements but also to enhance the efficiency of operations. With the integration of smart technology and advanced materials, these innovations promise to meet the increasing demands from researchers across various scientific disciplines. This article delves into the top innovations anticipated for 2025, highlighting how they will transform the landscape of research and laboratory practices. As we explore the future of lab pumps, it becomes evident that these technologies are not just tools but essential components that empower researchers to push the boundaries of discovery.

Why Precision Matters in Laboratory Pump Design

Precision in laboratory pump design is crucial for successful research outcomes. In scientific experimentation, even the slightest deviation in fluid delivery can lead to significant variances in results. For instance, in fields like pharmaceuticals and chemical analysis, accurate dosing is essential to ensure reproducibility and validity of findings. As innovative technologies emerge, lab pumps equipped with advanced sensors and automated controls are providing researchers with the ability to fine-tune flow rates and minimize errors.

**Tips:**

1. Always calibrate your pump before starting your experiments to ensure accuracy.

2. Consider investing in pumps with real-time monitoring capabilities to track performance and make necessary adjustments on the fly.

In addition to accuracy, efficiency in pump operation can greatly enhance productivity in the lab. Pumps that offer faster priming, self-venting features, and user-friendly interfaces allow researchers to focus more on their experiments rather than troubleshooting equipment. This not only streamlines workflows but also reduces the risk of human error, catering to the growing demand for high-throughput processing in various research applications. Ensuring precision in laboratory pump design is not just about achieving exact measurements; it is about empowering researchers to push the boundaries of innovation.

Why Innovative Materials Enhance Pump Performance

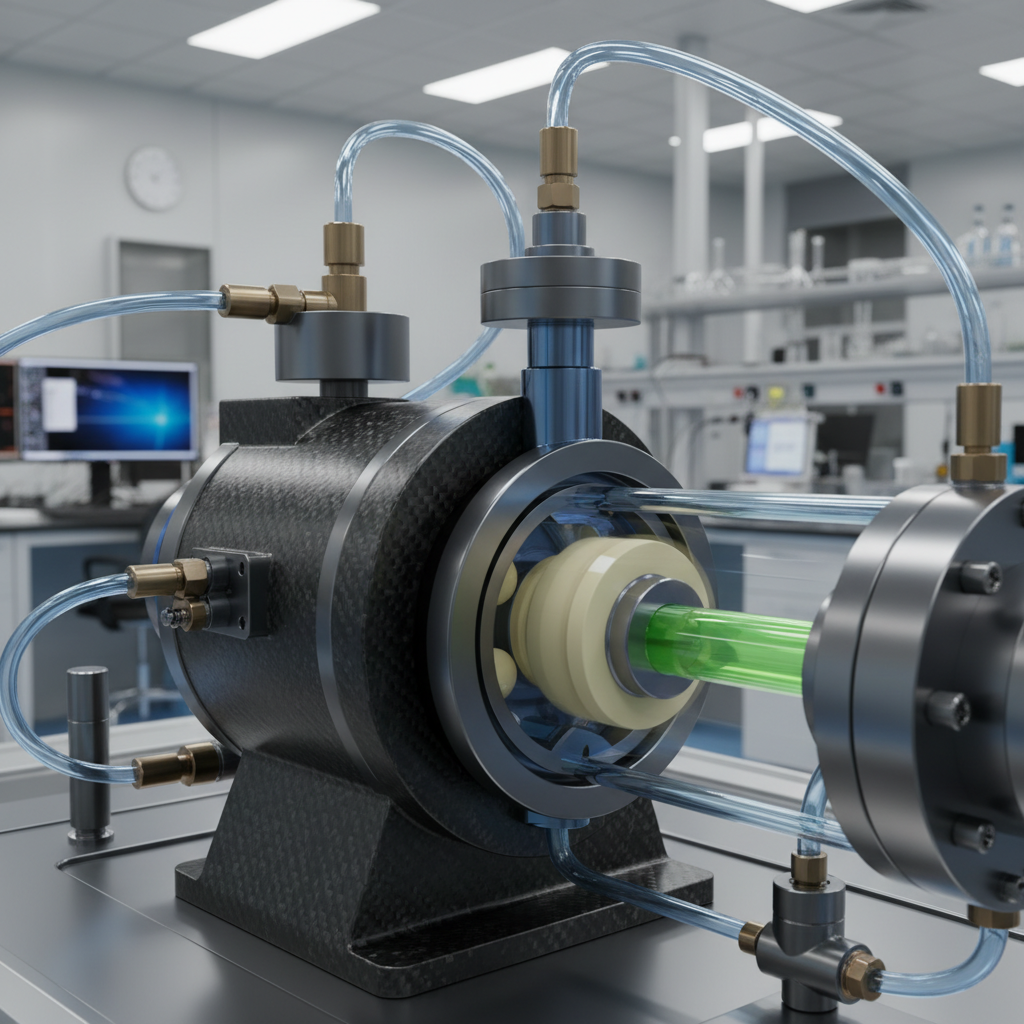

Innovative materials play a crucial role in enhancing pump performance, particularly in laboratory settings where precision and efficiency are paramount. The development of advanced composites and alloys has led to pumps that withstand corrosion, temperature fluctuations, and wear over time. For instance, the incorporation of ceramic materials has resulted in pumps that maintain their integrity under high pressures and aggressive chemical environments, significantly minimizing maintenance requirements and downtime.

Moreover, the advent of smart materials, which can adapt to varying operational conditions, has allowed for real-time monitoring and adjustments in pump performance. These materials not only improve the longevity of the pumps but also optimize fluid dynamics by reducing cavitation and turbulence. As a result, researchers can achieve more accurate and reproducible results in their experiments, thereby driving innovation in scientific inquiry and applications across various disciplines.

Why Smart Technology is Revolutionizing Lab Pump Efficiency

Smart technology is revolutionizing lab pump efficiency by integrating advanced sensors and automation into laboratory processes. According to a recent report by Lab Manager, the adoption of smart lab equipment, including pumps, has increased by over 30% in the past two years. These innovations not only optimize fluid control but also enhance data accuracy and operational reliability—reducing human error significantly. As a result, researchers can now achieve more precise dosing while streamlining workflows, which is crucial when conducting experiments that require meticulous measurements.

Tips for enhancing your lab pump efficiency include regular software updates to leverage the latest features and performance improvements. Additionally, consider investing in pumps equipped with real-time monitoring capabilities; these can alert users to potential issues before they escalate, minimizing downtime and saving resources. Leveraging big data analysis, many teams are also finding that predictive maintenance scheduling based on usage patterns can lead to a reduction in operational costs by up to 20%, showcasing the financial benefits of these smart technologies in laboratory settings.

2025 Top Lab Pump Innovations for Precision and Efficiency

Why Energy Efficiency in Lab Pumps is Crucial for Sustainability

Energy efficiency in laboratory pumps is becoming increasingly vital as research institutions and organizations strive for sustainability while maintaining high productivity. According to a report from the International Energy Agency (IEA), approximately 30% of energy consumed in research facilities is attributed to equipment, including pumps. This highlights the potential for significant energy savings through the adoption of more efficient laboratory pumps. By optimizing energy use, labs can reduce their carbon footprint while simultaneously lowering operational costs.

Recent innovations in pump technology focus on improving energy efficiency without compromising performance. For instance, advancements in variable speed drive pumps enable precise control over flow rates, leading to reduced energy consumption by up to 50% compared to traditional fixed-speed pumps. A study published by the American Chemical Society indicates that integrating smart technologies in lab pumps not only enhances accuracy but can also lead to up to 25% energy savings. As laboratory practices evolve, prioritizing energy-efficient pump systems will be essential in fostering a sustainable research environment, demonstrating a commitment to both efficiency and a greener future.

2025 Top Lab Pump Innovations for Precision and Efficiency in Research

| Innovation | Key Features | Energy Efficiency Rating | Applications | Sustainability Impact |

|---|---|---|---|---|

| Smart Flow Control | Adaptive flow monitoring with real-time feedback | A+ | Chemical analysis, pharmaceuticals | Reduces waste and conserves resources |

| Eco-Drive Technology | Low consumption operation; solar compatibility | A++ | Environmental research, field studies | Significantly lowers carbon footprint |

| Variable Speed Precision Pump | Customizable speed settings for varying viscosities | B+ | Biotechnology, cleanroom environments | Enhanced resource management |

| Compact peristaltic pump | Space-saving design with powerful output | A | Microfluidics, lab automation | Optimizes energy use in limited space |

| Integrated Monitoring Systems | Built-in sensors for flow and temperature | A+ | Food and beverage, chemical processing | Reduces errors and improves throughput |

Why User-Centric Features Improve Research Outcomes in Pump Design

In the rapidly evolving landscape of laboratory equipment, user-centric features in pump design are becoming increasingly pivotal for enhancing research outcomes. According to a report by Grand View Research, the global laboratory pump market is projected to reach $3.5 billion by 2025, driven largely by advancements in technology that prioritize user experience. Customizable settings, intuitive interfaces, and connectivity options are crucial elements that empower researchers to tailor their experiments more effectively. By focusing on the end-user's needs, manufacturers are creating pumps that not only increase efficiency but also reduce the potential for human error, ultimately leading to more reliable data.

Furthermore, a study published by the Journal of Laboratory Automation found that laboratories employing pumps with user-centric designs experienced a 30% increase in throughput—signifying the importance of functionality and ease of use in achieving research goals. Features such as real-time monitoring and integrated analytics allow researchers to adjust parameters on-the-fly, fostering an environment of innovation and adaptability. As the industry continues to evolve, the integration of user-centric designs in laboratory pump technology will undoubtedly remain a key factor in improving precision and efficiency in research settings.

Related Posts

-

Understanding the Essential Role of Lab Pumps in Modern Scientific Research

-

10 Expert Tips to Choose the Right Fluid Pump for Your Industrial Application

-

Revolutionizing Pump Systems with IoT Integration for Enhanced Efficiency and Performance

-

Unlocking Efficiency: The Ultimate Guide to Choosing the Right Chemical Pump for Your Industrial Needs

-

2025 Top Well Pumps: A Comprehensive Guide to Performance and Efficiency

-

How to Choose the Right Micro Pump: Key Factors and Industry Insights for Optimal Performance